Produkt podobny do:

FIX8™ • Płytka negatywowa • CNUX-RN

Toczenie ciężkie • Płytka z węglika spiekanego • Typ C negatywowy

Nr materiału6710688

Nr katalogowy ISOCNUX191024LRNNr katalogowy ANSICNUX6676LRN

- P Steel

- K Cast Iron

100788768

Turning

Facing

Chamfering

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Nr materiału | 6710688 |

| Nr katalogowy ISO | CNUX191024LRN |

| Nr katalogowy ANSI | CNUX6676LRN |

| Grade | KCP25B |

| Insert Hand | L |

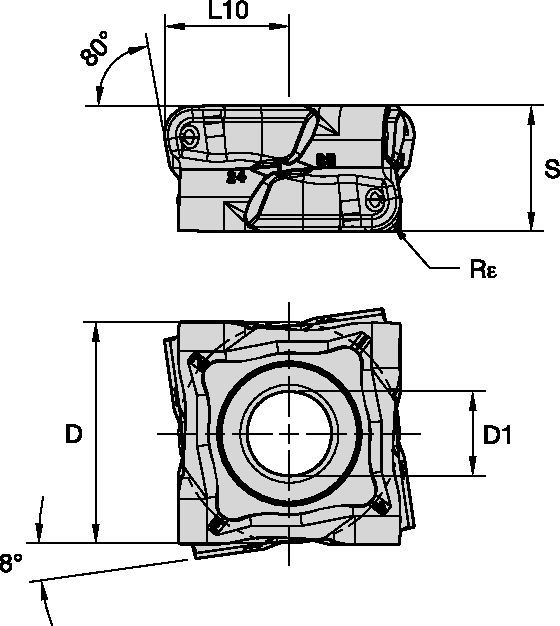

| [L10] Insert Cutting Edge Length | 19.344 mm |

| [L10] Insert Cutting Edge Length | 0.7616 in |

| [D] Insert IC Size | 19.05 mm |

| [D] Insert IC Size | 0.75 in |

| [D1] Insert Hole Size | 7.16 mm |

| [D1] Insert Hole Size | 0.2819 in |

| [S] Insert Thickness | 10.58 mm |

| [S] Insert Thickness | 0.4165 in |

| [W] Insert Width | 18.73 mm |

| [W] Insert Width | 0.7374 in |

| [Rε] Corner Radius | 2.4 mm |

| [Rε] Corner Radius | 0.094 in |

| INS_REG_AP_MAX_M | 4 mm |

| INS_REG_AP_MAX_I | 0.1575 in |

Materiały przedmiotu obrabianego

- Steel

- Cast Iron

Zastosowania

100788768

Turning

Facing

Chamfering

Gatunki

KCP25B

Composition: A tough cobalt-enriched carbide grade with a newly designed multilayer MTCVD-TiCN-Al2O3-TiOCN coating with superior interlayer adhesion.

Application: Best general-purpose turning grade for most steels and ferritic and martensitic stainless steels. The substrate design ensures adequate deformation resistance with excellent insert edge strength. Coating layers offer good wear resistance over a wide range of machining conditions and the post-coat treatment minimises microchipping and improves coating adhesion to substrate leading to long tool life and improved workpiece finishes.

Właściwości i zalety

- Inserts can withstand large cutting forces and vibrations due to the holder's rigid clamping system.

- Large depth of cut (up to 12mm) and feed rate (up to 1.4mm) ensure highest possible metal removal rates in steel, cast iron, and stainless steels.

- Ideal for medium machining and roughing reducing cost per edge.

- 8 cutting edges on the insert for higher productivity.

- Tangential design increases the amount of carbide between the workpiece and the tool holder, allowing the system to take higher loads.

- With 15% less cutting forces, FIX8 is also well suited for low horsepower lathes.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data