Produkt podobny do:

Płytki PCD • KSDR • E1

Płytki wymienne

Nr materiału6042985

Nr katalogowy ISOKSDR100031E1W4SNr katalogowy ASIKSDR100031E1W4S

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

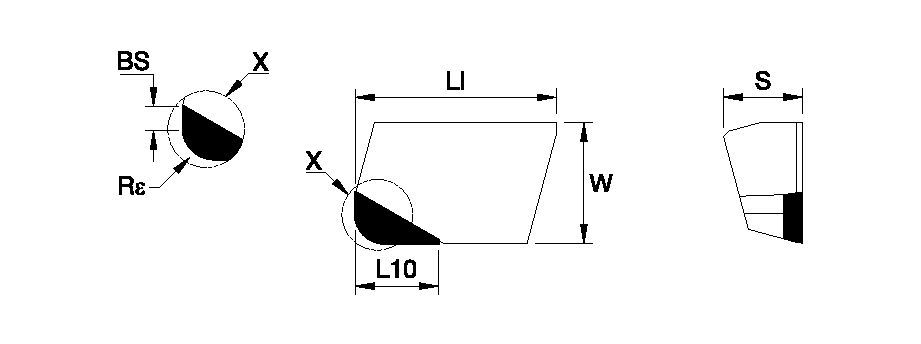

| Nr materiału | 6042985 |

| Nr katalogowy ISO | KSDR100031E1W4S |

| Nr katalogowy ASI | KSDR100031E1W4S |

| Grade | KD1425 |

| [W] Insert Width | 9.52 mm |

| [W] Insert Width | 0.375 in |

| [BS] Corner Facet Length | 1.52 mm |

| [BS] Corner Facet Length | 0.06 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| Average Chip Thickness [HM] | 0.02 mm |

| Average Chip Thickness [HM] | 0.0008 in |

Materiały przedmiotu obrabianego

- Non-Ferrous

Gatunki

KD1425

Composition: A multimodal PCD grade with a range of grain sizes brazed onto a carbide substrate.

Application: Engineered for extreme abrasion resistance, combined with good edge strength for demanding applications. An ideal choice for high-silicon aluminium alloys, bi-metallic (AL/GCI) materials, MMC, carbon-fibre reinforced plastics, and other abrasive non-metallic materials.

Właściwości i zalety

- Ap1 max = 6,3mm (.250")

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

Prędkości

Zalecane wyjściowe wartości prędkości skrawania [m/min]

| Grupa materiałowa | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 910 | 1980 | 4880 | 910 | 1980 | 4880 |

| 3 | 460 | 610 | 760 | 460 | 610 | 760 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

| Grupa materiałowa | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 910 | 1980 | 4880 | 910 | 1980 | 4880 |

| 3 | 460 | 610 | 760 | 460 | 610 | 760 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Grupa materiałowa | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 3000 | 6500 | 16000 | 3000 | 6500 | 16000 |

| 3 | 1500 | 2000 | 2500 | 1500 | 2000 | 2500 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

| Grupa materiałowa | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 3000 | 6500 | 16000 | 3000 | 6500 | 16000 |

| 3 | 1500 | 2000 | 2500 | 1500 | 2000 | 2500 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

Dobór płytek

Poradnik doboru płytek • KBDM

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| (Lekka geometria) | (Zgrubna geometria) | |||||

| odporność na zużycie |  | ciągliwość | ||||

| Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | .KSDR….. | KD1400 | .KSDR….. | KD1400 | .KSDR….. | KD1400 |

| N3 | .KSDR….. | KD1400 | .KSDR….. | KD1425 | .KSDR….. | KD1425 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| (Lekka geometria) | (Zgrubna geometria) | |||||

| odporność na zużycie |  | ciągliwość | ||||

| Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | .KSDR….. | KD1400 | .KSDR….. | KD1400 | .KSDR….. | KD1400 |

| N3 | .KSDR….. | KD1400 | .KSDR….. | KD1425 | .KSDR….. | KD1425 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data