Produkt podobny do:

NWC-E

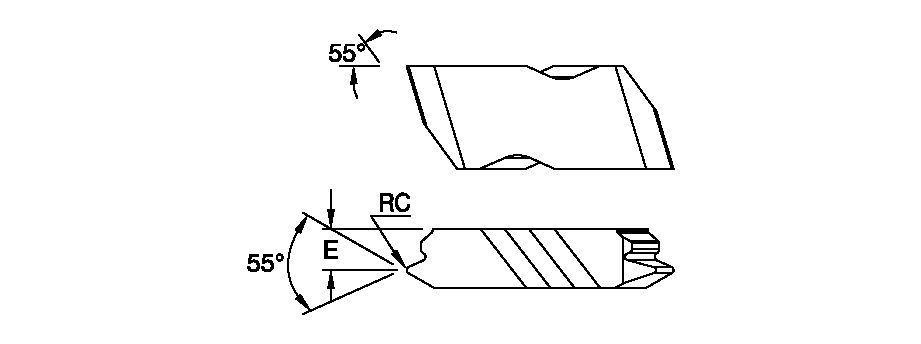

Płytki Top Notch™ do toczenia gwintów

Nr materiału1799500

Nr katalogowy ISONWC3R11ENr katalogowy ASINWC3R11E

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Nr materiału | 1799500 |

| Nr katalogowy ISO | NWC3R11E |

| Nr katalogowy ASI | NWC3R11E |

| Grade | KC5010 |

| Insert Size | 3 |

| Typ gwintu | BSW |

| [RC] Corner Radius Center | 0.3 mm |

| [RC] Corner Radius Center | 0.012 in |

| [E] Profile Distance | 3.429 mm |

| [E] Profile Distance | 0.135 in |

| TPI | 11 |

Materiały przedmiotu obrabianego

- Stainless Steel

- High-Temp Alloys

Gatunki

KC5010

Composition: An advanced PVD AlTiN coating over a very deformation-resistant unalloyed carbide substrate. The new and improved coating enables speeds to be increased by 50–100%.

Application: The KC5010 grade is ideal for finishing to general machining of most workpiece materials at higher speeds. Excellent for machining most steels, stainless steels, cast irons, non-ferrous materials, and super alloys under stable conditions. It also performs well machining hardened and short chipping materials.

Właściwości i zalety

- KENGold™ PVD, multilayer coating for easy wear-detection

- A positive chipbreaker that delivers very low cutting forces for excellent chip control

- Precision-ground inserts for accurate indexing, resulting in reliability and repeatability

- Improved cutting conditions for tool life, stability and rigidity

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data