Benzer Ürün:

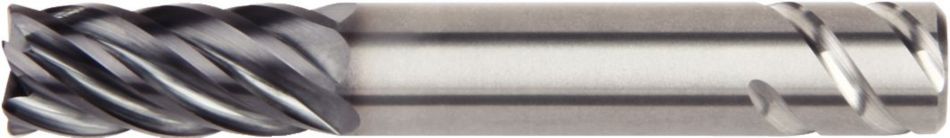

HARVI II™ • UCDE • Eşit Olmayan Ağız Aralığı

HARVI II™ • UCDE • Eşit Olmayan Ağız Aralığı

Ürün Numarası5351815

ISO Katalog NoUJDE375J6CSANSI Catalog NoUJDE375J6CS

- P Steel

- M Stainless Steel

- S High-Temp Alloys

- H Hardened Materials

Trochoidal Milling

Ramping: Blank

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 6

Helix Angle: 38°

Corner Style: Corner Radius

Corner Style: Square End

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Ürün Numarası | 5351815 |

| ISO Katalog No | UJDE375J6CS |

| ANSI Catalog No | UJDE375J6CS |

| Grade | KCSM15 |

| Adapter Style Machine Side | Straight-Cylindrical |

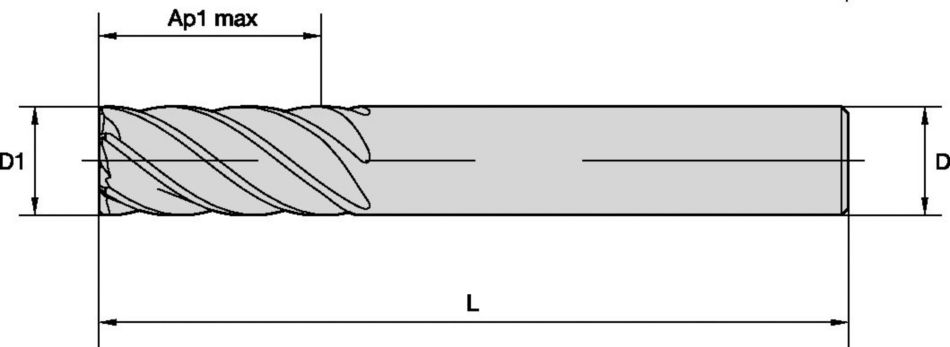

| [D1] Effective Cutting Diameter | 9.525 mm |

| [D1] Effective Cutting Diameter | 0.375 in |

| [D] Adapter / Shank / Bore Diameter | 9.525 mm |

| [D] Adapter / Shank / Bore Diameter | 0.375 in |

| [AP1MAX] 1st Maximum Cutting Depth | 25.4 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1 in |

| [L3] Usable Length | 35.7 mm |

| [L3] Usable Length | in |

| [L] Overall Length | 76.2 mm |

| [L] Overall Length | 3 in |

| [Z] Number of Flutes | 6 |

İş Parçası Malzemeleri

- Steel

- Stainless Steel

- High-Temp Alloys

- Hardened Materials

Kullanım ve uygulama alanları

Trochoidal Milling

Ramping: Blank

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 6

Helix Angle: 38°

Corner Style: Corner Radius

Corner Style: Square End

Kaliteler

KCSM15

Coated carbide grade with thick PVD coating and optimized chemistry

and process for increased wear resistance. Outstanding protection in milling stainless steel to mitigate crater, DOCN (depth-of-cut notching), and flank wear. Excellent performance up to 52 HRC.

Özellikler ve avantajlar

- Kennametal standardı.

- Merkezi olmayan kesme.

- Eşit Olmayan ağız aralığı daha düzgün işleme için tırlamayı en aza indirir.

- Daha az ayar için hem kaba hem de hassas işleme operasyonları için tek takım.

- Beş-ağız geometrisi 1 x D'ye kadar kanal frezelemeyi mümkün kılar.

İlerleme ve Devir hesaplamak için Çözüm Oluşturun

Bir çözüm oluşturduktan sonra, sadece İlerleme ve Devir simgesini seçin ve sistemimiz öneriler sunacaktır. Makinenizi ve teknik özelliklerinizi ekleyerek bilgileri özelleştirebilir veya kaydırıcıları kullanarak ayarlamalar yapabilirsiniz.

Uygulama bilgisi

HARVI III • UJDE • Unequal Flute Spacing • Roughing

| Malzeme grubu |  | KCSM15A | Recommended feed per tooth (IPT = inch/th) for side milling. | ||||||||||

| Kesme hızı | D1 | ||||||||||||

| frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | 1 1/2 | ||||||

| ap | ae | min | max | dec. | 0.3750 | 0.5000 | 0.6250 | 0.7500 | 1.0000 | 1.2500 | 1.5000 | ||

| P | 4 | Ap max | 0.4 x D | 300 | 490 | IPT | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0039 | 0.0040 | 0.0040 |

| 5 | Ap max | 0.4 x D | 200 | 330 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | 0.0039 | 0.0039 | |

| M | 1 | Ap max | 0.4 x D | 300 | 380 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | 0.0048 | 0.0048 |

| 2 | Ap max | 0.4 x D | 200 | 260 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | 0.0039 | 0.0039 | |

| 3 | Ap max | 0.4 x D | 200 | 230 | IPT | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | 0.0029 | 0.0029 | |

| S | 1 | Ap max | 0.4 x D | 160 | 300 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | 0.0048 | 0.0048 |

| 2 | Ap max | 0.4 x D | 80 | 160 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | 0.0026 | 0.0026 | |

| 3 | Ap max | 0.4 x D | 80 | 130 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | 0.0026 | 0.0026 | |

| 4 | Ap max | 0.4 x D | 160 | 200 | IPT | 0.0017 | 0.0021 | 0.0025 | 0.0028 | 0.0033 | 0.0036 | 0.0036 | |

| H | 1 | Ap max | 0.4 x D | 260 | 460 | IPT | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0039 | 0.0040 | 0.0040 |

| 2 | Ap max | 0.4 x D | 230 | 390 | IPT | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | 0.0029 | 0.0029 | |

HARVI III • UJDE • Unequal Flute Spacing • Finishing

|  | |||||||||||

| Dik kenar frezeleme (A) | KCSM15 | Recommended feed per tooth (IPT=inch/th) for side milling. | ||||||||||

| Kesme hızı | D1 | |||||||||||

| frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | ||||||

| Malzeme grubu | ap | ae | min | max | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | |

| P | 4 | Ap max | 0.06 x D | 560 | 940 | IPT | .0025 | .0031 | .0036 | .0040 | .0046 | .0048 |

| 5 | Ap max | 0.06 x D | 370 | 620 | IPT | .0022 | .0028 | .0033 | .0037 | .0043 | .0047 | |

| M | 1 | Ap max | 0.06 x D | 560 | 720 | IPT | .0027 | .0035 | .0041 | .0046 | .0054 | .0058 |

| 2 | Ap max | 0.06 x D | 370 | 500 | IPT | .0022 | .0028 | .0033 | .0037 | .0043 | .0047 | |

| 3 | Ap max | 0.06 x D | 370 | 440 | IPT | .0018 | .0023 | .0027 | .0030 | .0034 | .0035 | |

| S | 1 | Ap max | 0.06 x D | 310 | 560 | IPT | .0027 | .0035 | .0041 | .0046 | .0054 | .0058 |

| 2 | Ap max | 0.06 x D | 160 | 250 | IPT | .0015 | .0018 | .0022 | .0025 | .0029 | .0032 | |

| 3 | Ap max | 0.06 x D | 160 | 250 | IPT | .0015 | .0018 | .0022 | .0025 | .0029 | .0032 | |

| 4 | Ap max | 0.06 x D | 310 | 370 | IPT | .0020 | .0026 | .0030 | .0034 | .0040 | .0043 | |

| H | 1 | Ap max | 0.06 x D | 500 | 870 | IPT | .0025 | .0031 | .0036 | .0040 | .0046 | .0048 |

Tolerans

| Parmak freze toleransları | |||

| D1 | Tolerans | D | Tolerans h6 + / - |

| All | +.000/- .002" | ≤1/8" | +0/-.00024" |

| +0/-.00031" | |||

| +0/-.00035" | |||

| +0/-.00043" | |||

| 0/.00051" | |||

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data