The Boron Nitride Advantage

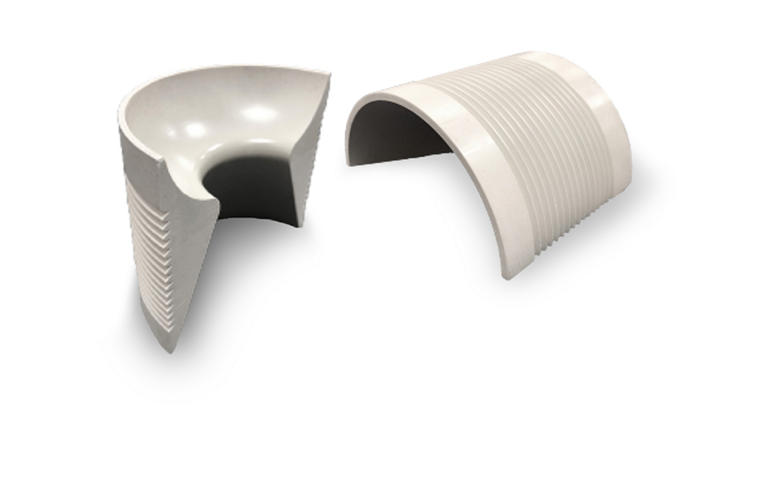

Boron nitride is a high temperature ceramic that has a structure similar to graphite. Our portfolio of hot-pressed solid materials includes pure hexagonal boron nitride as well as composites suitable for applications requiring excellent thermal properties combined with electrical isolation.

Easily machinable and fast availability make boron nitride an outstanding choice for prototypes to large quantities requiring its unique properties.