Benzer Ürün:

B210_SGL (~3 x D) • B211_SGL (~5 x D) • B212_SGL (~8 x D) • KCMS15 • A-Shank • SGL Drills

SGL Matkaplar • Paslanmaz çelik • İçten soğutmalı

Ürün Numarası6350606

ISO Katalog NoB212A12500SGLANSI Catalog NoB212A12500SGL

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Drilling: Stacked Plates

Drilling

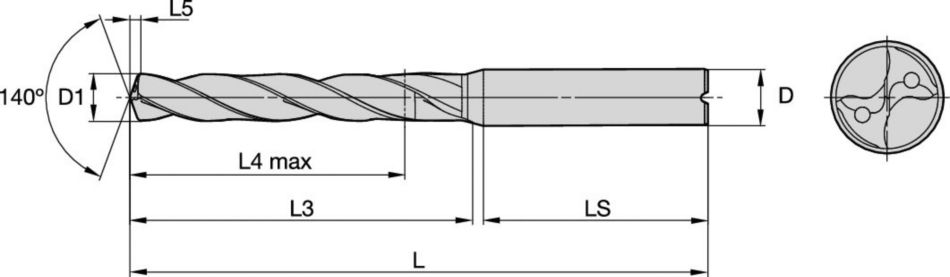

Tool Dimensions: 2flute/2margin/coolant

DIN number 6535

DIN number 6537

Drilling - Through Coolant

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling Depth: 3x

Drilling Depth: 5x

Drilling Depth: 8x

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Ürün Numarası | 6350606 |

| ISO Katalog No | B212A12500SGL |

| ANSI Catalog No | B212A12500SGL |

| Grade | KCMS15 |

| [D1] Drill Diameter M | 12.5 mm |

| [D1] Drill Diameter M | 0.4921 in |

| [L] Overall Length | 176 mm |

| [L] Overall Length | 6.9291 in |

| [L3] Flute Length | 128 mm |

| [L3] Flute Length | 5.0394 in |

| [L4] Maximum Drilling Depth | 112 mm |

| [L4] Maximum Drilling Depth | 4.4094 in |

| [L5] Drill Point Length | 1.85 mm |

| [L5] Drill Point Length | 0.0728 in |

| [LS] Shank Length | 45 mm |

| [LS] Shank Length | 1.7717 in |

| [D] Adapter / Shank / Bore Diameter | 14 mm |

| [D] Adapter / Shank / Bore Diameter | 0.5512 in |

İş Parçası Malzemeleri

- Steel

- Stainless Steel

- High-Temp Alloys

Kullanım ve uygulama alanları

Drilling: Stacked Plates

Drilling

Tool Dimensions: 2flute/2margin/coolant

DIN number 6535

DIN number 6537

Drilling - Through Coolant

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling Depth: 3x

Drilling Depth: 5x

Drilling Depth: 8x

Kaliteler

KCMS15

Composition: Monolayer PVD AlTiN coated fine-grain carbide with superior surface finish.

Application: First choice for stainless steel and high-temperature-resistant materials. The coating offers high hardness and excellent wear resistance, as well as enhanced high-temperature properties increasing its applicability also to MQL machining of steel.

Özellikler ve avantajlar

- SGL drills with through coolant for stainless steel and high-temperature alloys.

- By combining unique Kennametal features such as the all new SGL-Point-Geometry with a patented gashing, an unique Flute Design and a best in class coating into one tool, the B21*SGL drill is the ultimate high volume production tool.

- All new SGL point geometry with improved web thinning and patented gashing which migrate in a straight cutting edge enables high cutting parameters (feeds), improves hole quality and creates controlled chips which leads to a reliable performance.

- KCMS15 grade is a Monolayer PVD AlTiN coated fine grain carbide with superior surface finish. First choice for stainless steel, high-temperature resistant materials. The coating offers high hardness and excellent wear resistance as well as enhanced high-temperature properties increasing its applicability also to MQL machining of steel.

- The highly polished surface ensures superior chip evacuation even when low-pressure coolant is applied.

- Ideal point angle and tolerance make the B21_SGL series the preffered pilot drill for B27_SGL series Solid Carbide deep Hole Drills.

İlerleme ve Devir hesaplamak için Çözüm Oluşturun

Bir çözüm oluşturduktan sonra, sadece İlerleme ve Devir simgesini seçin ve sistemimiz öneriler sunacaktır. Makinenizi ve teknik özelliklerinizi ekleyerek bilgileri özelleştirebilir veya kaydırıcıları kullanarak ayarlamalar yapabilirsiniz.

Uygulama bilgisi

| Malzeme grubu |  |  | |||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | |||||||||||

| Malzeme grubu |  |  | |||||||||||

| Malzeme grubu | Kesme hızı | İnç | |||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | |||||||||||

|  | ||||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Malzeme grubu | Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| P | 1 | 110 | 160 | 210 | mm/r | 0,05–0,13 | 0,08–0,19 | 0,11–0,24 | 0,14–0,30 | 0,16–0,35 | 0,18–0,39 | 0,20–0,46 | 0,23–0,51 |

| 2 | 130 | 170 | 210 | mm/r | 0,05–0,13 | 0,08–0,17 | 0,11–0,20 | 0,14–0,24 | 0,16–0,28 | 0,18–0,32 | 0,20–0,37 | 0,23–0,41 | |

| 3 | 110 | 150 | 190 | mm/r | 0,08–0,13 | 0,12–0,19 | 0,14–0,24 | 0,17–0,30 | 0,20–0,35 | 0,22–0,39 | 0,26–0,46 | 0,29–0,51 | |

| 4 | 80 | 120 | 150 | mm/r | 0,08–0,12 | 0,11–0,18 | 0,12–0,23 | 0,15–0,28 | 0,17–0,33 | 0,19–0,37 | 0,22–0,43 | 0,25–0,48 | |

| 5 | 60 | 80 | 90 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,14–0,24 | 0,16–0,26 | |

| 6 | 60 | 70 | 80 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,14–0,24 | 0,16–0,26 | |

| M | 1 | 60 | 80 | 90 | mm/r | 0,04–0,08 | 0,06–0,14 | 0,08–0,19 | 0,11–0,21 | 0,13–0,23 | 0,14–0,24 | 0,16–0,26 | 0,19–0,29 |

| 2 | 50 | 80 | 80 | mm/r | 0,04–0,08 | 0,06–0,14 | 0,08–0,19 | 0,11–0,21 | 0,13–0,23 | 0,14–0,24 | 0,16–0,26 | 0,19–0,29 | |

| 3 | 40 | 50 | 70 | mm/r | 0,04–0,07 | 0,06–0,10 | 0,08–0,14 | 0,09–0,17 | 0,10–0,20 | 0,12–0,22 | 0,14–0,24 | 0,16–0,27 | |

| S | 1 | 20 | 20 | 20 | mm/r | 0,03–0,08 | 0,04–0,09 | 0,05–0,11 | 0,05–0,11 | 0,08–0,14 | 0,11–0,16 | 0,14–0,19 | 0,16–0,21 |

| 2 | 10 | 20 | 30 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,11 | 0,08–0,14 | 0,11–0,16 | 0,14–0,19 | 0,16–0,21 | |

| 3 | 10 | 20 | 50 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,11 | 0,08–0,14 | 0,11–0,16 | 0,14–0,19 | 0,16–0,21 | |

| 4 | 30 | 50 | 60 | mm/r | 0,03–0,04 | 0,04–0,05 | 0,06–0,08 | 0,08–0,10 | 0,11–0,13 | 0,13–0,15 | 0,14–0,18 | 0,16–0,20 | |

Tolerans

| Tolerans • Metrik | ||

| Anma ölçüsü aralığı | D1 Tolerans m7 | D Tolerans h6 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 | |

| Tolerans • İnç | ||

| Anma ölçüsü aralığı | D1 Tolerans m7 | D Tolerans h6 |

| .0002/.0006 | .0000/-.0003 | |

| .0002/.0008 | .0000/-.0004 | |

| .0003/.0010 | .0000/-.0004 | |

| .0003/.0011 | .0000/-.0005 | |

Dimension

Kennametal Karbür Matkaplar için Boyutlar (B* Serileri)

| mm | KISA TİP* | UZUN TİP* | EKSTRA UZUN** | |||||||||

| Ø | DIN 6535 | ~3 x D | ~5 x D | ~8 x D (SGL) | ||||||||

| D1 min | D1 maks | D | LS min | L | L3 | L4 | L | L3 | L4 | L | L3 | L4 |

| 2,301 | 2,999 | 4 | 28 | 58 | 17 | 12 | 58 | 22 | 17 | 66 | 30 | 25 |

| 3,000 | 3,750 | 6 | 36 | 62 | 20 | 14 | 66 | 28 | 23 | 78 | 40 | 33 |

| 3,751 | 4,750 | 6 | 36 | 66 | 24 | 17 | 74 | 36 | 29 | 87 | 49 | 41 |

| 4,751 | 6,000 | 6 | 36 | 66 | 28 | 20 | 82 | 44 | 35 | 94 | 56 | 48 |

| 6,001 | 7,000 | 8 | 36 | 79 | 34 | 24 | 91 | 53 | 43 | 105 | 67 | 57 |

| 7,001 | 8,000 | 8 | 36 | 79 | 41 | 29 | 91 | 53 | 43 | 121 | 82 | 64 |

| 8,001 | 10,000 | 10 | 40 | 89 | 47 | 35 | 103 | 61 | 49 | 145 | 102 | 80 |

| 10,001 | 12,000 | 12 | 45 | 102 | 55 | 40 | 118 | 71 | 56 | 170 | 122 | 96 |

| 12,001 | 14,000 | 14 | 45 | 107 | 60 | 43 | 124 | 77 | 60 | 190 | 142 | 112 |

| 14,001 | 16,000 | 16 | 48 | 115 | 65 | 45 | 133 | 83 | 63 | 213 | 162 | 128 |

| 16,001 | 18,000 | 18 | 48 | 123 | 73 | 51 | 143 | 93 | 71 | 232 | 181 | 144 |

| 18,001 | 20,000 | 20 | 50 | 131 | 79 | 55 | 153 | 101 | 77 | 254 | 201 | 160 |

| 20,001 | 22,000 | 20 | 50 | 141 | 86 | 60 | 167 | 112 | 85 | 274 | 221 | 176 |

| 22,001 | 25,000 | 25 | 56 | 153 | 95 | 65 | 184 | 126 | 98 | 310 | 251 | 200 |

| * D1 20 mm, DIN 6537K standardına göre | ||||||||||||

| * D1 | ||||||||||||

| ** Fabrika standardına göre | ||||||||||||

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data