Produit similaire à:

Drill Fix™ DFSP™ • Plaquettes FP

Drill Fix™ DFSP™ • Plaquettes FP

Numéro de matériel4042890

Ref. ISO CatalogueSPPX09T310FPRef. ANSI CatalogueSPPX09T310FP

- P Acier

- K Fonte

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Numéro de matériel | 4042890 |

| Ref. ISO Catalogue | SPPX09T310FP |

| Ref. ANSI Catalogue | SPPX09T310FP |

| Nuance | KCPK10 |

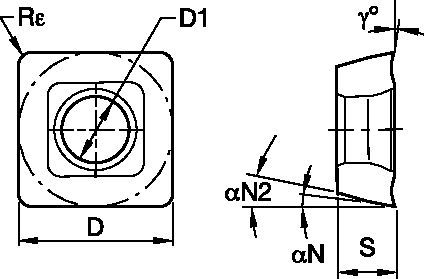

| [D] Taille de plaquette CI | 9.525 mm |

| [D] Taille de plaquette CI | 0.375 in |

| [D1] Taille du trou de la plaquette | 3.6 mm |

| [D1] Taille du trou de la plaquette | 0.1417 in |

| [S] Épaisseur de la plaquette | 3.97 mm |

| [S] Épaisseur de la plaquette | 0.1563 in |

| [Rε] Rayon de bec | 1 mm |

| [Rε] Rayon de bec | 0.039 in |

| [GAA] Angle de coupe de la plaquette | 6 |

| [Angle de dépouille majeur | 7 |

| Deuxième angle de dépouille majeur | 11 |

Matériaux de pièce à usiner

- Acier

- Fonte

Grades

KCPK10

Composition : Revêtement TiCN-Al2O3 CVD sur un nouveau substrat carbure enrichi au cobalt.

Application : La nuance KCPK10 est une combinaison équilibrée de résistance à la déformation et de ténacité des arêtes qui offre une excellente résistance à l'abrasion et à l'usure en cratère dans l'usinage à grande vitesse de l'acier et de la fonte. S'utilise à vitesse de coupe supérieure et vitesse d'avance faible à moyenne.

Features and benefits

- Four cutting edges per insert

- High positive chipbreaker geometry preferred for use on ductile and normal chipping materials

- Additional inserts with increased corner radius support use with Beyond™ grades

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Données d'application

| Métrique | |||||||||||||||

| Groupe Matières | Condition | Logement | Géométrie | Nuance | Vitesse de coupe | Plage des avances (fz) par diamètre | |||||||||

| Plage | |||||||||||||||

| Mini | Valeur initiale | Maxi | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| P | 1 | S | O | MD | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 |

| I | MD | KC7140 | |||||||||||||

| U | O | FP | KCU25 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | MD | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | FP | KCU25 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | MD | KCPK10 | 260 | 285 | 320 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | FP | KCU25 | 180 | 195 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 110 | 120 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 4 | S | O | FP | KCPK10 | 220 | 250 | 300 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU25 | 150 | 180 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 90 | 110 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 5 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 6 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| Métrique | |||||||||||||||

| Vitesse de coupe | Métrique | ||||||||||||||

| Plage | Plage des avances (fz) par diamètre | ||||||||||||||

| Groupe Matières | condition | Logement | Géométrie | Nuance | Mini | Valeur initiale | Maxi | Ø | SPGX05 DFTX2 14,00-17,49 | SPGX06 DFT03 17,50-21,99 | SPGX07 DFT05 22.00-25,99 | SPGX09 DFT05 26.00-32,99 | SPGX12 DFT06/..07 33,00-43,99 | SPGX15 DFT07/..09 44,00-55,00 | |

| P | 1 | S | O | MD | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 |

| 1 | S | I | MD | KC7140 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 1 | U | O | FP | KCU25 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | U | I | MD | KC7140 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | I | I | MD | KC7140 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | S | O | MD | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 2 | S | I | MD | KC7140 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 2 | U | O | FP | KCU25 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | U | I | MD | KC7140 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | I | I | MD | KC7140 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | S | O | MD | KCPK10 | 260 | 285 | 320 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 3 | S | I | MD | KC7140 | 260 | 285 | 320 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 3 | U | O | FP | KCU25 | 180 | 195 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | U | I | MD | KC7140 | 180 | 195 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | I | O | HP | KCU40 | 110 | 120 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | I | I | MD | KC7140 | 110 | 120 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | S | O | FP | KCPK10 | 220 | 250 | 300 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 4 | S | I | MD | KC7140 | 220 | 250 | 300 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 4 | U | O | HP | KCU25 | 150 | 180 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | U | I | MD | KC7140 | 150 | 180 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | I | O | HP | KCU40 | 90 | 110 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | I | I | MD | KC7140 | 90 | 110 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 5 | S | I | MD | KC7140 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 5 | U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | U | I | MD | KC7140 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | I | I | MD | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 6 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 6 | S | I | MD | KC7140 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 6 | U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 6 | U | I | MD | KC7140 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 6 | I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 6 | I | I | MD | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| Métrique | |||||||||||||||

| Groupe Matières | Condition | Logement | Géométrie | Nuance | Vitesse de coupe | Plage des avances (fz) par diamètre | |||||||||

| Plage | |||||||||||||||

| Mini | Valeur initiale | Maxi | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| M | 1 | S | O | FP | KCU25 | 150 | 190 | 230 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 |

| I | MD | KC7140 | |||||||||||||

| U | O | MD | KCU40 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | FP | KCU25 | 150 | 180 | 210 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| I | MD | KC7140 | |||||||||||||

| U | O | MD | KCU40 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | HP | KCU25 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| I | HP | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 80 | 110 | 140 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | |||||||||||||

| Métrique | |||||||||||||||

| Vitesse de coupe | |||||||||||||||

| Plage | Plage des avances (fz) par diamètre | ||||||||||||||

| Groupe Matières | Condition | Logement | Géométrie | Nuance | Mini | Valeur initiale | Maxi | Ø | SPGX05 DFTX2 14,00–17,49 | SPGX06 DFT03 17,50–21,99 | SPGX07 DFT05 22.00–25,99 | SPGX09 DFT05 26.00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | |

| M | 1 | S | O | FP | KCU25 | 150 | 190 | 230 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 |

| 1 | S | I | MD | KC7140 | 150 | 190 | 230 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | U | O | MD | KCU40 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 1 | U | I | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 1 | I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 1 | I | I | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 2 | S | O | FP | KCU25 | 150 | 180 | 210 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | S | I | MD | KC7140 | 150 | 180 | 210 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | U | O | MD | KCU40 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 2 | U | I | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 2 | I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 2 | I | I | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 3 | S | O | HP | KCU25 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | S | I | HP | KC7140 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | U | O | HP | KCU40 | 80 | 110 | 140 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 3 | U | I | HP | KC7140 | 80 | 110 | 140 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 3 | I | O | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 3 | I | I | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| Métrique | |||||||||||||||

| Groupe Matières | Condition | Logement | Géométrie | Nuance | Vitesse de coupe | Plage des avances (fz) par diamètre | |||||||||

| Plage | |||||||||||||||

| Mini | Valeur initiale | Maxi | Ø | ||||||||||||

| N | 1 | S | O | LP | KCU40 | 150 | 190 | 230 | mm/r | 0,06-0,08 | 0,06-0,10 | 0,08-0,12 | 0,10-0,16 | 0,12-0,021 | 0,14-0,024 |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/r | 0,05-0,07 | 0,06-0,08 | 0,07-0,10 | 0,05-0,10 | 0,06-0,013 | 0,08-0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 2 | S | O | LP | KCU40 | 150 | 180 | 210 | mm/r | 0,06–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,16 | 0,12–0,021 | 0,14–0,024 | |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/r | 0,05-0,07 | 0,06-0,08 | 0,07-0,10 | 0,05-0,10 | 0,06-0,013 | 0,08-0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 3 | S | O | LP | KCU40 | 150 | 190 | 230 | mm/r | 0,06-0,08 | 0,06-0,10 | 0,08-0,12 | 0,10-0,16 | 0,12-0,021 | 0,14-0,024 | |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/r | 0,05-0,07 | 0,06-0,08 | 0,07-0,10 | 0,05-0,10 | 0,06-0,013 | 0,08-0,014 | ||

| I | DS | KCU40 | |||||||||||||

| Métrique | |||||||||||||||

| Vitesse de coupe | |||||||||||||||

| Plage | Plage des avances (fz) par diamètre | ||||||||||||||

| Groupe Matières | Condition | Logement | Géométrie | Nuance | Mini | Valeur initiale | Maxi | Ø | SPGX05 DFTX2 14,00–17,49 | SPGX06 DFT03 17,50–21,99 | SPGX07 DFT05 22.00–25,99 | SPGX09 DFT05 26.00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | |

| K | 1 | S | O | FP | KCPK10 | 200 | 240 | 300 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 |

| 1 | S | I | HP | KCU40 | 200 | 240 | 300 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 1 | U | O | FP | KCU25 | 120 | 155 | 200 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | U | I | HP | KC7140 | 120 | 155 | 200 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | I | O | FP | KC7140 | 80 | 100 | 125 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | I | I | HP | KC7140 | 80 | 100 | 125 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | S | O | FP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 2 | S | I | HP | KCU40 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 2 | U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | U | I | HP | KC7140 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | I | O | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | I | I | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | S | O | HP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 3 | S | I | HP | KCU40 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 3 | U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | U | I | HP | KC7140 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | I | O | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | I | I | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| Métrique | |||||||||||||||

| Groupe Matières | Condition | Logement | Géométrie | Nuance | Vitesse de coupe | Plage des avances (fz) par diamètre | |||||||||

| Plage | |||||||||||||||

| Mini | Valeur initiale | Maxi | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| K | 1 | S | O | FP | KCPK10 | 200 | 240 | 300 | mm/tr | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 |

| I | HP | KCU40 | |||||||||||||

| U | O | FP | KCU25 | 120 | 155 | 200 | mm/tr | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | FP | KC7140 | 80 | 100 | 125 | mm/tr | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | HP | KC7140 | |||||||||||||

| 2 | S | O | FP | KCPK10 | 180 | 220 | 260 | mm/tr | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 110 | 140 | 170 | mm/tr | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 80 | 100 | 120 | mm/tr | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | HP | KC7140 | |||||||||||||

| 3 | S | O | HP | KCPK10 | 180 | 220 | 260 | mm/tr | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 110 | 140 | 170 | mm/tr | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 80 | 100 | 120 | mm/tr | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | HP | KC7140 | |||||||||||||

| N | 1 | S | O | LP | KCU40 | 150 | 190 | 230 | mm/tr | 0,06–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,16 | 0,12–0,021 | 0,14–0,024 |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/tr | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/tr | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 2 | S | O | LP | KCU40 | 150 | 180 | 210 | mm/tr | 0,06–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,16 | 0,12–0,021 | 0,14–0,024 | |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/tr | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/tr | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 3 | S | O | LP | KCU40 | 150 | 190 | 230 | mm/tr | 0,06–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,16 | 0,12–0,021 | 0,14–0,024 | |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/tr | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/tr | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,014 | ||

| I | DS | KCU40 | |||||||||||||

| Métrique | |||||||||||||||

| Vitesse de coupe | |||||||||||||||

| Plage | Plage des avances (fz) par diamètre | ||||||||||||||

| Groupe Matières | Condition | Logement | Géométrie | Nuance | Mini | Valeur initiale | Maxi | Ø | SPGX05 DFTX2 14,00–17,49 | SPGX06 DFT03 17,50–21,99 | SPGX07 DFT05 22.00–25,99 | SPGX09 DFT05 26.00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | |

| N | 1 | S | O | HP | KCPK10 | 350 | 500 | 650 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 |

| 1 | S | I | HP | KMF | 350 | 500 | 650 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 1 | U | O | HP | KCU40 | 300 | 400 | 500 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | U | I | HP | KMF | 300 | 400 | 500 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | I | O | HP | KCU40 | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | I | I | HP | KMF | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | S | O | HP | KCPK10 | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 2 | S | I | HP | KMF | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 2 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | U | I | HP | KMF | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | I | O | HP | KCU40 | 175 | 250 | 325 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | I | I | HP | KMF | 175 | 250 | 325 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | S | O | HP | KCPK10 | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 3 | S | I | HP | KMF | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 3 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | U | I | HP | KMF | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | I | O | HP | KCU40 | 150 | 250 | 350 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | I | I | HP | KMF | 150 | 250 | 350 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | S | O | HP | KCU25 | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 4 | S | I | HP | KC7140 | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 4 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 4 | U | I | HP | KC7140 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 4 | I | O | HP | KCU40 | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | I | I | HP | KC7140 | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | S | O | HP | KCU40 | 400 | 450 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 5 | S | I | HP | KMF | 400 | 450 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 5 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 5 | U | I | HP | KMF | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 5 | I | O | HP | KCU40 | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | I | I | HP | KMF | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| Métrique | |||||||||||||||

| Groupe Matières | Condition | Logement | Géométrie | Nuance | Vitesse de coupe | Plage des avances (fz) par diamètre | |||||||||

| Plage | |||||||||||||||

| Mini | Valeur initiale | Maxi | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| S | 1 | S | O | HP | KCU40 | 60 | 70 | 75 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 40 | 50 | 60 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| 4 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| Métrique | |||||||||||||||

| Vitesse de coupe | |||||||||||||||

| Plage | Plage des avances (fz) par diamètre | ||||||||||||||

| Groupe Matières | Condition | Logement | Géométrie | Nuance | Mini | Valeur initiale | Maxi | Ø | SPGX05 DFTX2 14,00–17,49 | SPGX06 DFT03 17,50–21,99 | SPGX07 DFT05 22.00–25,99 | SPGX09 DFT05 26.00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | |

| S | 1 | S | O | HP | KCU40 | 60 | 70 | 75 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 |

| 1 | S | I | MD | KC7140 | 60 | 70 | 75 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 1 | U | O | HP | KCU40 | 40 | 50 | 60 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 1 | U | I | MD | KC7140 | 40 | 50 | 60 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 1 | I | O | HP | KCU40 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 1 | I | I | MD | KC7140 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 2 | S | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 2 | S | I | MD | KC7140 | 50 | 60 | 70 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 2 | U | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 2 | U | I | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 2 | I | O | HP | KCU40 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 2 | I | I | MD | KC7140 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 3 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 3 | S | I | MD | KC7140 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 3 | U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 3 | U | I | MD | KC7140 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 3 | I | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 3 | I | I | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 4 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 4 | S | I | MD | KC7140 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 4 | U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 4 | U | I | MD | KC7140 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 4 | I | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 4 | I | I | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data