Bienvenue

Veuillez confirmer vos préférences

Mettre à jour les préférences

Suggestions de produit

Product Family suggestions

Kennametal à votre service

Support Clients

Nouveau client

Êtes-vous un nouveau client de Kennametal ? Créez un compte et commencez.

Créer un compteBonjour, User Name

Votre compte sélectionné :

Il y a un problème avec votre compte. Veuillez contacter le service client.

Compte Client Modifier le compte

Compte de livraison Modifier le compte

- Tableau de bord

- Gérer les commandes

- Gérer les canaux

- Carnet d’adresses

Notifications

Mark all as read- Modifier le mot de passe

- Mon profil

- Se déconnecter

Article(s) ajoutées avec succès au panier

Voir le panier

Voir le panier

Kennametal à votre service

Support Clients

Article(s) ajoutées avec succès au panier

Voir le panier

Voir le panier

Édition de la Solution

Ajout de Solution

Nom de la Solution:{{SolutionName}}- Produits

- /

- Outils d’usinage des métaux

- /

- Fraisage

- /

- Fraises en carbure monobloc

- /

- Fraises en carbure monobloc hautes performances

- /

- PCD End Mills

- /

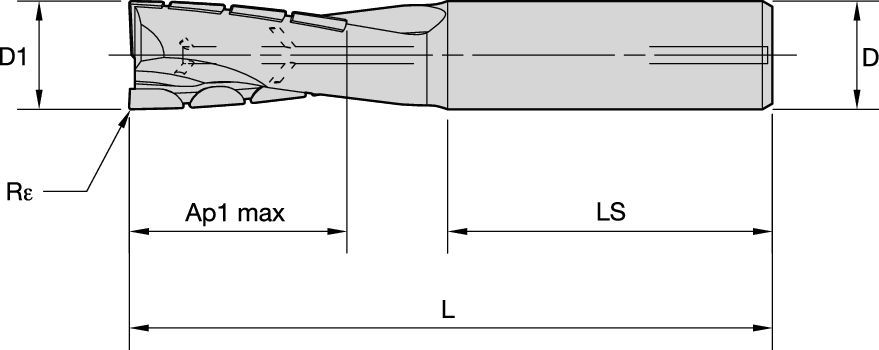

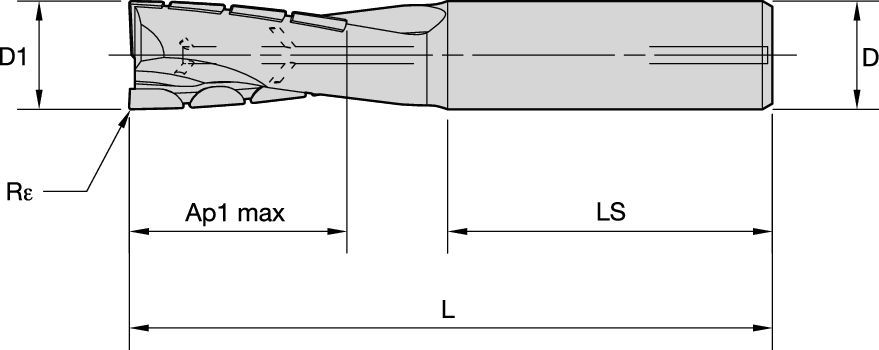

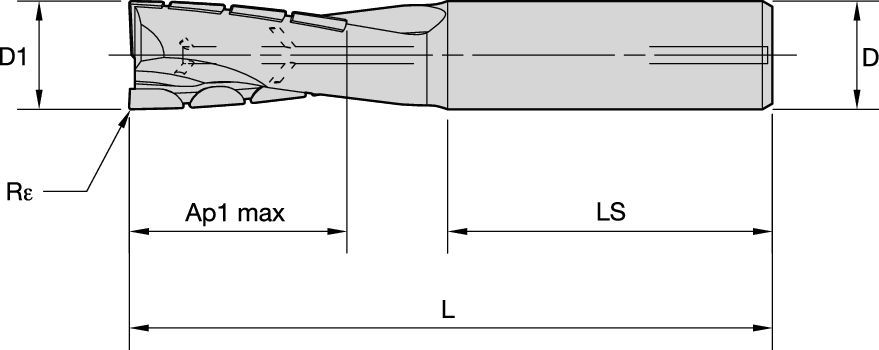

- KenCut™ AQ • ALCR • Rayonnée • 2 dents • 2 x D • Arrosage interne • Queue cylindrique • Métrique

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

KenCut™ AQ • ALCR • Rayonnée • 2 dents • 2 x D • Arrosage interne • Queue cylindrique • Métrique

KenCut™ AQ Fraise en PCD pour l'ébauche et la finition de l'aluminium

Features and benefits

- Fraises à queue avec diamant polycristallin (PCD) pour l'usinage de l'aluminium à grande vitesse, réduisant considérablement le temps d'usinage.

- Les fraises PCD offrent une productivité jusqu'à dix fois supérieure à celle des fraises en carbure monobloc.

- Prête pour une quantité minimale de lubrifiant (Paré pour MQL).

- Les arêtes de coupe vives et les faces de coupe à faibles frottements garantissent des états de surface de grande qualité.

- Coupe au centre pour opérations de plongée et de ramping.

Uses and application

Drilling

Trochoidal Milling

Slotting: Square End

100665610

Surfaçage

Fraisage hélicoïdal

Fraisage en plongée

Ramping : Ébauche

Rainurage : Bout plat

Fraisage de côté/avec épaulement : Bout plat

Usinage de poches

Fraisage de côté/avec épaulement : Ébauche

| Malzeme grubu |  |  | KD1410 | Dik kenar frezeleme (A) için diş başına önerilen ilerleme (fz = mm/Diş). Kanal frezeleme (B) için fz %20 azaltılır. | |||||||

| A | B | Kesme hızı; | D1 | ||||||||

| ap | ae | ap | Min. | Maks. | mm | 12,0 | 16,0 | 20,0 | |||

| N | 1 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 3000 | Fz | 0,140 | 0,160 | 0,160 |

| 2 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 3000 | Fz | 0,140 | 0,160 | 0,160 | |

| 3 | 2 x D | 0,2 x D | 0,5 x D | 180 | – | 1400 | Fz | 0,120 | 0,140 | 0,140 | |

| 4 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 800 | Fz | 0,100 | 0,120 | 0,120 | |

| 5 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 1000 | Fz | 0,090 | 0,100 | 0,100 | |

| 6 | 2 x D | 0,2 x D | 0,5 x D | 150 | – | 800 | Fz | 0,060 | 0,080 | 0,080 | |

| 7 | 2 x D | 0,2 x D | 0,5 x D | 250 | – | 500 | Fz | 0,060 | 0,080 | 0,080 | |

| Malzeme grubu |  |  | KD1410 | Dik kenar frezeleme (A) için diş başına önerilen ilerleme (fz = mm/Diş). Kanal frezeleme (B) için fz %20 azaltılır. | |||||||

| A | B | Kesme hızı; | D1 | ||||||||

| ap | ae | ap | Min. | Maks. | mm | 12,0 | 16,0 | 20,0 | |||

| N | 1 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 3000 | Fz | 0,140 | 0,160 | 0,160 |

| 2 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 3000 | Fz | 0,140 | 0,160 | 0,160 | |

| 3 | 2 x D | 0,2 x D | 0,5 x D | 180 | – | 1400 | Fz | 0,120 | 0,140 | 0,140 | |

| 4 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 800 | Fz | 0,100 | 0,120 | 0,120 | |

| 5 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 1000 | Fz | 0,090 | 0,100 | 0,100 | |

| 6 | 2 x D | 0,2 x D | 0,5 x D | 150 | – | 800 | Fz | 0,060 | 0,080 | 0,080 | |

| 7 | 2 x D | 0,2 x D | 0,5 x D | 250 | – | 500 | Fz | 0,060 | 0,080 | 0,080 | |