Bienvenue

Veuillez confirmer vos préférences

Mettre à jour les préférences

Suggestions de produit

Product Family suggestions

Kennametal à votre service

Support Clients

Nouveau client

Êtes-vous un nouveau client de Kennametal ? Créez un compte et commencez.

Créer un compteBonjour, User Name

Votre compte sélectionné :

Il y a un problème avec votre compte. Veuillez contacter le service client.

Compte Client Modifier le compte

Compte de livraison Modifier le compte

- Tableau de bord

- Gérer les commandes

- Gérer les canaux

- Carnet d’adresses

Notifications

Mark all as read- Modifier le mot de passe

- Mon profil

- Se déconnecter

Article(s) ajoutées avec succès au panier

Voir le panier

Voir le panier

Kennametal à votre service

Support Clients

Article(s) ajoutées avec succès au panier

Voir le panier

Voir le panier

Édition de la Solution

Ajout de Solution

Nom de la Solution:{{SolutionName}}- Produits

- /

- HARVI II™ • UGDE • Unequal Flute Spacing • inch

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

HARVI II™ • UGDE • Unequal Flute Spacing • inch

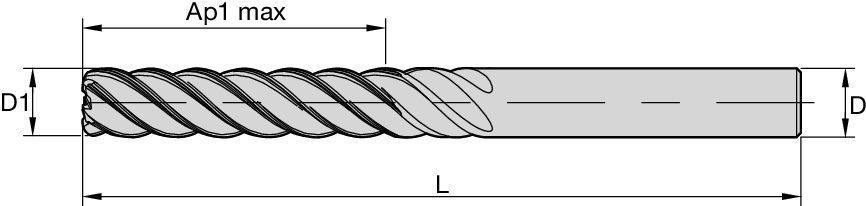

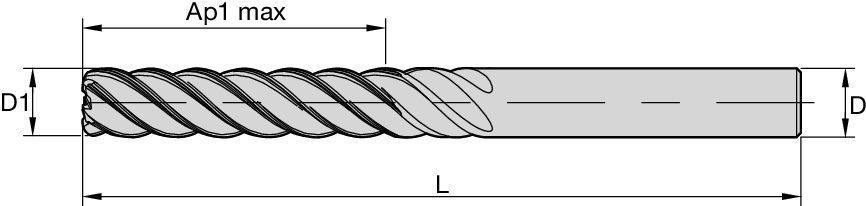

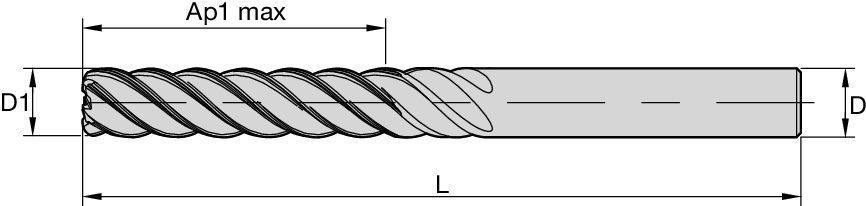

HARVI™ II Long Solid Carbide End Mill for Finishing and Fine Finishing Applications

Features and benefits

- Kennametal standard dimensions.

- Non-center cutting.

- Unequal flute spacing minimizes chatter for smoother machining.

- For finishing and semi-finishing applications.

Uses and application

Trochoidal Milling

Fraisage de côté/avec épaulement : Bout plat

Dimensions de l'outil : Configuration des goujures : 5

Style de bec : Rayon de bec

Style de bec : Bout plat

Angle d'hélice : 43°

| End Mill Tolerances | |||

| D1 | tolerance | D | tolerance h6 + / - |

| All | +.000/- .002" | ≤1/8" | +0/-.00024" |

| +0/-.00031" | |||

| +0/-.00035" | |||

| +0/-.00043" | |||

| 0/.00051" | |||

HARVI II • UGDE • Unequal Flute Spacing • 3 x D Lengths of Cut

| Material |  | KCSM15A | Recommended feed per tooth (IPT = inch/th) for side milling. | ||||||||||

| Cutting Speed | D1 | ||||||||||||

| frac. | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||

| ap | ae | min | max | dec. | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||

| P | 0 | Apmax | 0.05 x D | 980 | 1310 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0034 | 0.0039 | 0.0044 | 0.0049 |

| 1 | Apmax | 0.05 x D | 980 | 1310 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0034 | 0.0039 | 0.0044 | 0.0049 | |

| 2 | Apmax | 0.05 x D | 920 | 1250 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0034 | 0.0039 | 0.0044 | 0.0049 | |

| 3 | Apmax | 0.05 x D | 790 | 1050 | IPT | 0.0015 | 0.0020 | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | |

| 4 | Apmax | 0.05 x D | 590 | 980 | IPT | 0.0014 | 0.0017 | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0039 | |

| 5 | Apmax | 0.05 x D | 390 | 660 | IPT | 0.0012 | 0.0016 | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | |

| 6 | Apmax | 0.05 x D | 330 | 490 | IPT | 0.0010 | 0.0013 | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | |

| M | 1 | Apmax | 0.05 x D | 590 | 750 | IPT | 0.0015 | 0.0020 | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 |

| 2 | Apmax | 0.05 x D | 390 | 520 | IPT | 0.0012 | 0.0016 | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | |

| 3 | Apmax | 0.05 x D | 390 | 460 | IPT | 0.0010 | 0.0013 | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | |

| K | 1 | Apmax | 0.05 x D | 790 | 980 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0034 | 0.0039 | 0.0044 | 0.0049 |

| 2 | Apmax | 0.05 x D | 720 | 920 | IPT | 0.0015 | 0.0020 | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | |

| 3 | Apmax | 0.05 x D | 720 | 850 | IPT | 0.0012 | 0.0016 | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | |

| S | 1 | Apmax | 0.05 x D | 330 | 590 | IPT | 0.0015 | 0.0020 | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 |

| 2 | Apmax | 0.05 x D | 160 | 330 | IPT | 0.0008 | 0.0010 | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 3 | Apmax | 0.05 x D | 160 | 260 | IPT | 0.0008 | 0.0010 | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | |

| 4 | Apmax | 0.05 x D | 330 | 390 | IPT | 0.0011 | 0.0014 | 0.0017 | 0.0021 | 0.0025 | 0.0028 | 0.0033 | |

| H | 1 | Apmax | 0.05 x D | 520 | 920 | IPT | 0.0014 | 0.0017 | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0039 |

| 2 | Apmax | 0.05 x D | 460 | 790 | IPT | 0.0010 | 0.0013 | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | |