Product Similar To :

HARVI™ II Long • Radiused • 5 Flutes • 5 x D • Plain Shank • Metric

HARVI™ II Long Solid Carbide End Mill for Finishing and Fine Finishing Applications

Material Number7077933

ISO Catalog IDHA2L5RA0600X030HAR100MANSI Catalog IDHA2L5RA0600X030HAR100M

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Trochoidal Milling

Side Milling/Shoulder Milling: Square End

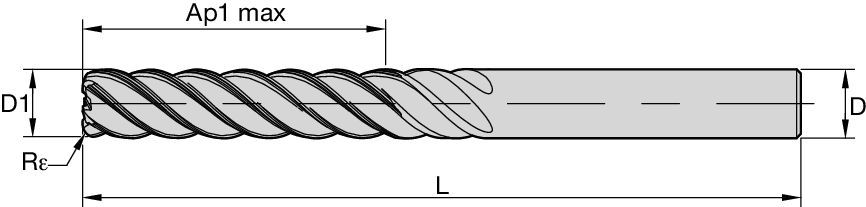

Tool Dimensions: Flute Configuration: 5

Corner Style: Corner Radius

Helix Angle: 43°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 7077933 |

| ISO Catalog ID | HA2L5RA0600X030HAR100M |

| ANSI Catalog ID | HA2L5RA0600X030HAR100M |

| Grade | KCSM15A |

| Adapter Style Machine Side | Straight-Cylindrical |

| [D1] Effective Cutting Diameter | 6 mm |

| [D1] Effective Cutting Diameter | 0.2362 in |

| [D] Adapter / Shank / Bore Diameter | 6 mm |

| [D] Adapter / Shank / Bore Diameter | 0.2362 in |

| [AP1MAX] 1st Maximum Cutting Depth | 30 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.1811 in |

| [L3] Usable Length | 33.9 mm |

| [L3] Usable Length | 1.3346 in |

| [L] Overall Length | 76 mm |

| [L] Overall Length | 2.9921 in |

| [Re] Corner Radius | 1 mm |

| [Re] Corner Radius | 0.039 in |

| [Z] Number of Flutes | 5 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Uses and application

Trochoidal Milling

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 5

Corner Style: Corner Radius

Helix Angle: 43°

Features and benefits

- Versatile solid carbide end mill for semi-finishing and finishing of thin walls and deep pockets in titanium, steels and stainless steels with excellent surface finishes

- HARVI™ II long solid carbide end mills cover side milling operations and dynamic milling

- HARVI™ II long solid carbide end mills feature unequal flute spacing for chatter-free machining at highest feed rates

- Back taper design for excellent wall straightness

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

HARVI™ II • UGDE • Unequal Flute Spacing • 3 x D Lengths of Cut

| Material |  | KCSM15A | Recommended feed per tooth (fz = mm/th) for side milling. | |||||||||||

| Cutting Speed | D1 | |||||||||||||

| ap | ae | Min | Max | mm | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 25,0 | ||

| P | 0 | ap max | 0,05 x D | 300 | 400 | Fz | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,114 | 0,124 |

| 1 | ap max | 0,05 x D | 300 | 400 | Fz | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,114 | 0,124 | |

| 2 | ap max | 0,05 x D | 280 | 380 | Fz | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,114 | 0,124 | |

| 3 | ap max | 0,05 x D | 240 | 320 | Fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,101 | 0,114 | |

| 4 | ap max | 0,05 x D | 180 | 300 | Fz | 0,033 | 0,045 | 0,054 | 0,062 | 0,070 | 0,077 | 0,088 | 0,098 | |

| 5 | ap max | 0,05 x D | 120 | 200 | Fz | 0,029 | 0,040 | 0,048 | 0,056 | 0,063 | 0,070 | 0,081 | 0,091 | |

| 6 | ap max | 0,05 x D | 100 | 150 | Fz | 0,025 | 0,034 | 0,040 | 0,047 | 0,052 | 0,057 | 0,065 | 0,071 | |

| M | 1 | ap max | 0,05 x D | 180 | 230 | Fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,101 | 0,114 |

| 2 | ap max | 0,05 x D | 120 | 160 | Fz | 0,029 | 0,040 | 0,048 | 0,056 | 0,063 | 0,070 | 0,081 | 0,091 | |

| 3 | ap max | 0,05 x D | 120 | 140 | Fz | 0,025 | 0,034 | 0,040 | 0,047 | 0,052 | 0,057 | 0,065 | 0,071 | |

| K | 1 | ap max | 0,05 x D | 240 | 300 | Fz | 0,044 | 0,060 | 0,072 | 0,083 | 0,092 | 0,101 | 0,114 | 0,124 |

| 2 | ap max | 0,05 x D | 220 | 280 | Fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,101 | 0,114 | |

| 3 | ap max | 0,05 x D | 220 | 260 | Fz | 0,029 | 0,040 | 0,048 | 0,056 | 0,063 | 0,070 | 0,081 | 0,091 | |

| S | 1 | ap max | 0,05 x D | 100 | 180 | Fz | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,101 | 0,114 |

| 2 | ap max | 0,05 x D | 50 | 100 | Fz | 0,019 | 0,026 | 0,032 | 0,037 | 0,042 | 0,046 | 0,054 | 0,061 | |

| 3 | ap max | 0,05 x D | 50 | 80 | Fz | 0,019 | 0,026 | 0,032 | 0,037 | 0,042 | 0,046 | 0,054 | 0,061 | |

| 4 | ap max | 0,05 x D | 100 | 120 | Fz | 0,026 | 0,037 | 0,045 | 0,052 | 0,058 | 0,064 | 0,074 | 0,084 | |

| H | 1 | ap max | 0,05 x D | 160 | 280 | Fz | 0,033 | 0,045 | 0,054 | 0,062 | 0,070 | 0,077 | 0,088 | 0,098 |

| 2 | ap max | 0,05 x D | 140 | 240 | Fz | 0,025 | 0,034 | 0,040 | 0,047 | 0,052 | 0,057 | 0,065 | 0,071 | |

Tolerance

| End Mill Tolerances | |||

| D1 | tolerance e8 | D | tolerance h6 + / - |

| ≤3 | -0,014/-0,028 | ≤3 | +0/-0,006 |

| -0,020/-0,038 | +0/-0,008 | ||

| -0,025/-0,047 | +0/-0,009 | ||

| -0,032/-0,059 | +0/-0,011 | ||

| -0,040/-0,073 | +0/-0,013 | ||

I have read and accepted the Terms & Conditions of use