A Winning Formula to Combat Abrasion, Erosion and Corrosion

As pioneers in the field of infiltration brazed tungsten carbide cladding, Kennametal Conforma Clad™ spent four decades developing and refining high end wear solutions for industry. We utilize three standard tungsten carbide cladding formulas - WC200, WC210, WC219- that provide superior wear protection for a wide range of operating conditions and wear modes. In addition to the standard tungsten carbide cladding formulas, we also offer custom formulations to fit specific customer requirements.

Our engineers evaluate each substrate and operating environment to determine the best cladding formula for your specific application.

Conforma Clad vs Standard Wear Solutions

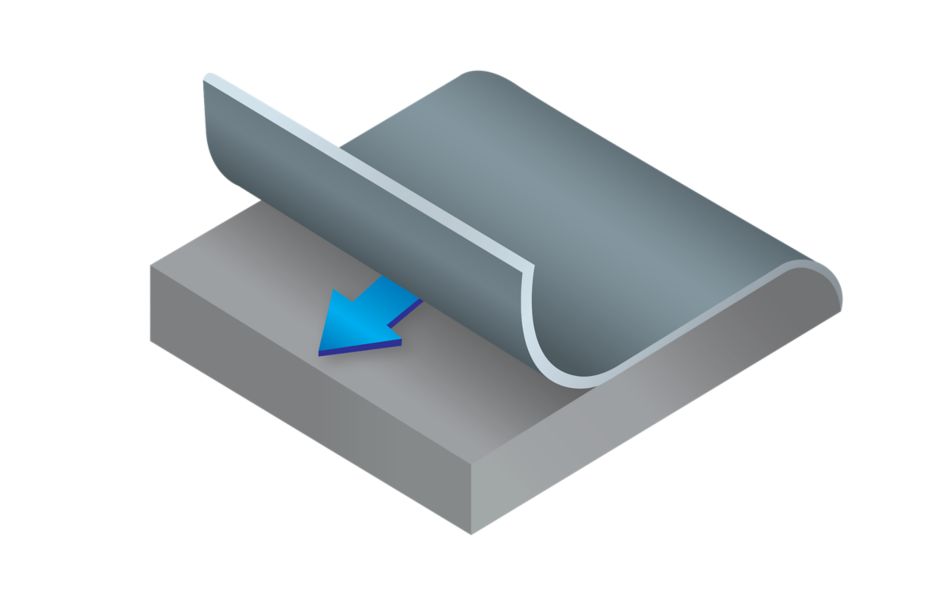

The Conforma Clad process produces claddings with densely loaded particles of tungsten carbide, resulting in exceptional resistance to abrasion and erosion relative to other hardfacing solutions such as chrome carbide weld overlay and thermal sprays.

- Cladding microstructure is consistent throughout, with minimal dilution and a tight interface between cladding and substrate. This consistency facilitates wear monitoring while parts are in service as the cladding will wear uniformly from top to bottom.

- Cladding has minimal porosity, typically less than 3 percent, and no interconnected porosity.

- Cladding has a strong metallurgical bond (>70,000 psi), ensuring no unexpected loss of protection in application such as flaking or spalling.

- Cladding can be used in operating temperatures up to approximately 1850°F and has excellent high temperature erosion resistance in fine particle erosion streams.

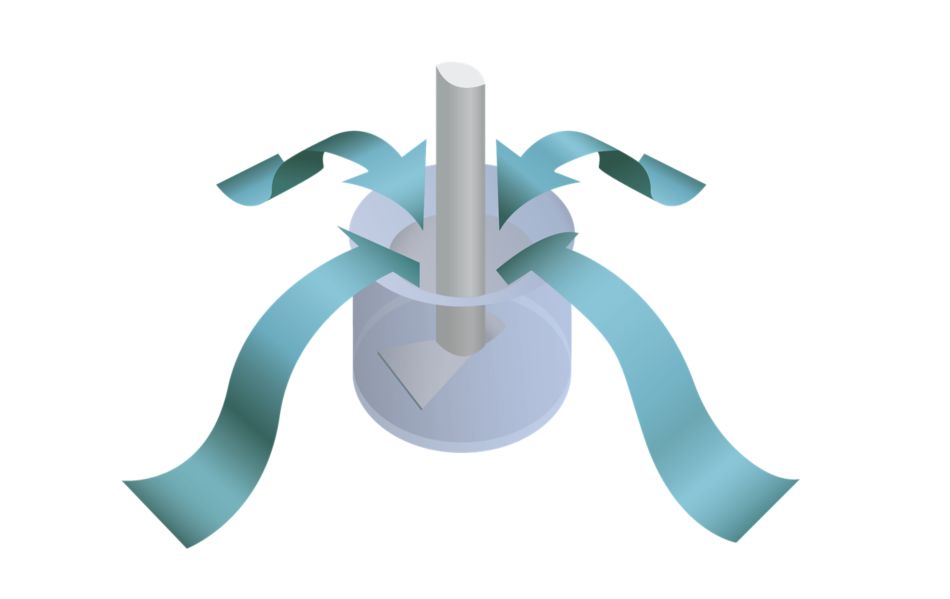

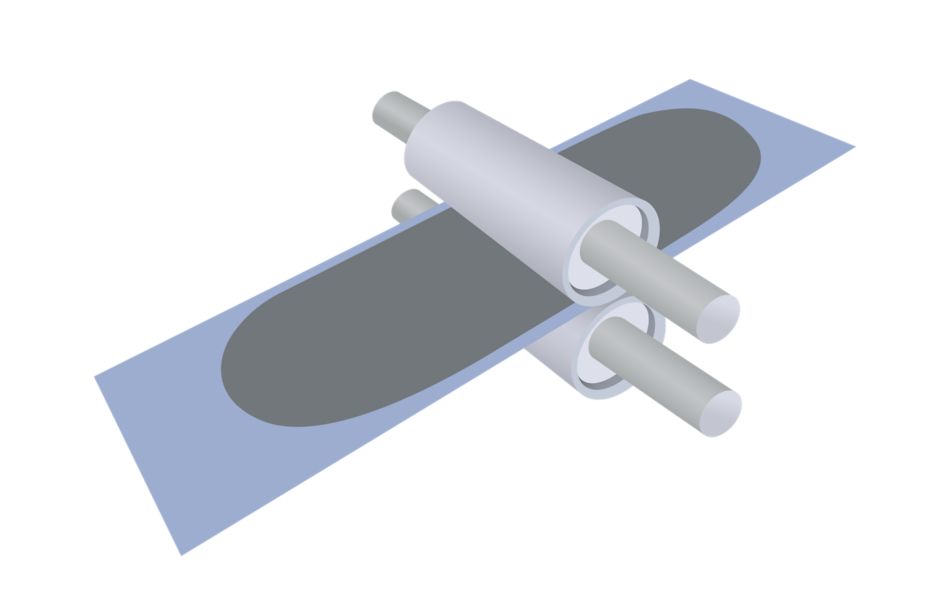

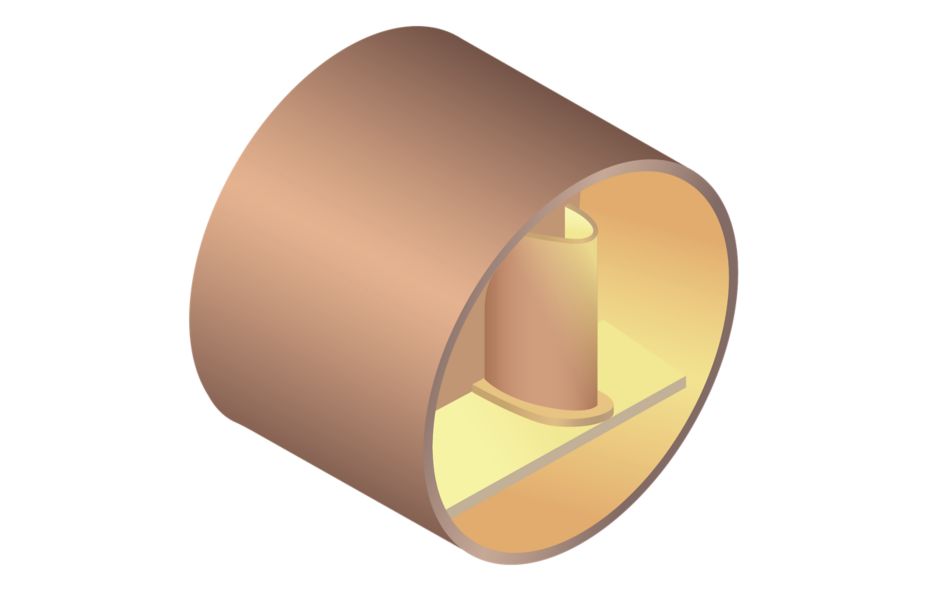

- Cladding can be applied to complex geometries, inside diameters, and other non-line-of-site surfaces that are unreachable by other methods.

Third party testing has shown that 1/16” of Conforma Clad cladding is equivalent to 1” of chrome carbide weld overlay or 3” of carbon steel plate in fly ash erosion applications, making it the solution of choice when weight considerations are paramount, such as fans.