Product Similar To :

KenTIP™ FS • Insert • HPC Geometry

Modular Drilling • Carbide Insert for KenTIP™ FS

Material Number6370406

ISO Catalog IDKTFST21433HPCMANSI Catalog IDKTFST08438HPC

- K Cast Iron

Drilling

Drilling: Inclined Exit

Drilling: Stacked Plates

100160773

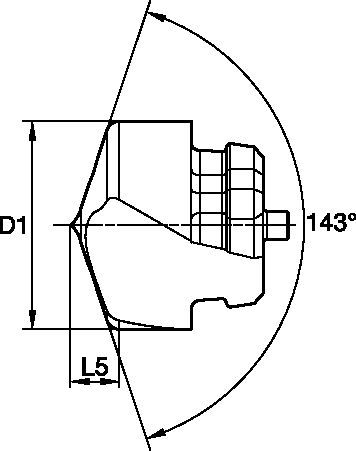

Tool Dimensions: 2flute/4margin/coolant

Drilling: Cross-Hole Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6370406 |

| ISO Catalog ID | KTFST21433HPCM |

| ANSI Catalog ID | KTFST08438HPC |

| Grade | KC7410 |

| [D1] Drill Diameter | 21.432 mm |

| [D1] Drill Diameter | 0.8438 in |

| [L5] Drill Point Length | 4.95 mm |

| [L5] Drill Point Length | 0.1949 in |

| [SSC] Insert Seat Size | Z |

Workpiece Materials

- Cast Iron

Uses and application

Drilling

Drilling: Inclined Exit

Drilling: Stacked Plates

100160773

Tool Dimensions: 2flute/4margin/coolant

Drilling: Cross-Hole Drilling

Grades

KC7410

Composition: Multilayered PVD AlCrN-based coated fine-grain carbide.

Application: First choice for cast iron. Due to the uniquely developed coating, this grade exhibits extraordinary wear resistance in abrasive materials offering the highest material removal rates.

Features and benefits

- HPC point geometry for highest performance in cast iron.

- Four margin lands ensure hole straightness.

- Large corner radius to prevents chipping and reduces exit burs when drilling through holes.

- Through coolant.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

| Material | Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate per Rev | |||||||||||||

| Min | Starting Value | Max | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| K | 1 | 100 | 175 | 200 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 |

| 2 | 100 | 160 | 180 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 | |

| 3 | 70 | 85 | 120 | mm/r | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,21 | 0,28 | 0,32 | 0,33 | |

| Material | Cutting Speed | Inch | ||||||||||||

| Range | Recommended Feed Rate per Rev | |||||||||||||

| Min | Starting Value | Max | .236 | .315 | .394 | .472 | .551 | .630 | .787 | .945 | 1.023 | |||

| K | 1 | 330 | 570 | 660 | IPR | .005 | .005 | .006 | .007 | .009 | .010 | .012 | .014 | .015 |

| 2 | 330 | 520 | 590 | IPR | .005 | .005 | .006 | .007 | .009 | .010 | .012 | .014 | .015 | |

| 3 | 230 | 280 | 390 | IPR | .004 | .005 | .005 | .006 | .007 | .008 | .011 | .013 | .013 | |

| Material | Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate per Rev | |||||||||||||

| Min | Starting Value | Max | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| K | 1 | 100 | 175 | 200 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 |

| 2 | 100 | 160 | 180 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 | |

| 3 | 70 | 85 | 120 | mm/r | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 – 0,42 | 0,21 | 0,28 | 0,32 | 0,33 | |

Tolerance

| Tolerance • Metric | |

| D1 metric | tolerance k8 |

| 6 | 0,000/+0,018 |

| 0,000/+0,022 | |

| 0,000/+0,027 | |

| 0,000/+0,033 | |

| Tolerance • Inch | |

| D1 inch | tolerance k8 |

| 0.2362 | 0.0000/+0.0007 |

| 0.0000/+0.0009 | |

| 0.0000/+0.0011 | |

| 0.0000/+0.0013 | |

I have read and accepted the Terms & Conditions of use