Advancing E-Vehicle Manufacturing

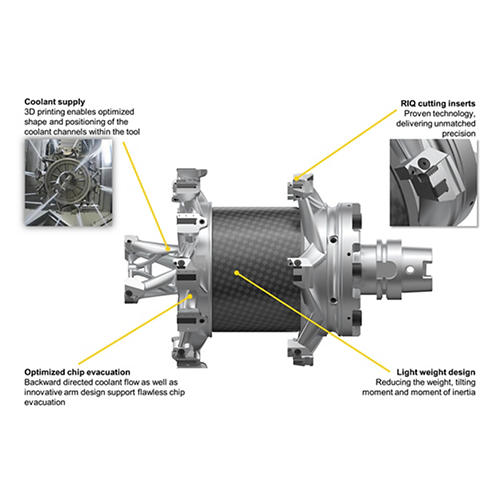

As automotive manufacturers expand their hybrid and electric vehicle offerings, Kennametal is leveraging the design flexibility of additive manufacturingto meet growing customer demand for lighter weight tooling solutions for machining e-vehicle components. Our innovative 3D-printed stator bore tool—combined with a carbon-fiber-body and our proven RIQ inserts technology—delivers unmatched productivity and reliability in the production of large diameter, deep bore electric motor housings.