Drill Fix™ DFSP™ • MD 刀片

Drill Fix™ DFSP™ • MD 刀片

物料号5534257

公制样本编号SPGX070304MD英制样本编号SPGX070304MD

- P 钢

- M 不锈钢

- K 铸铁

- N 非铁材质

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

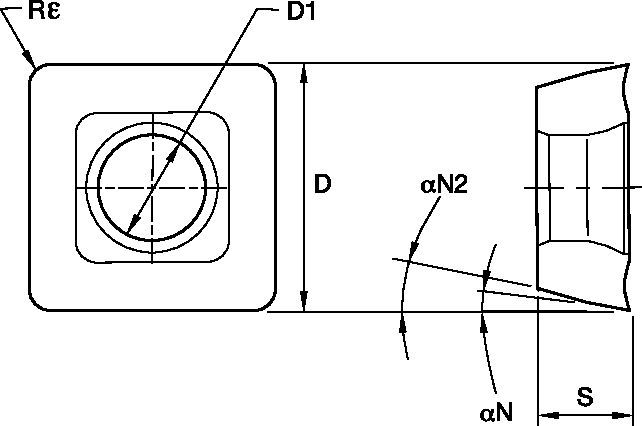

| 物料号 | 5534257 |

| 公制样本编号 | SPGX070304MD |

| 英制样本编号 | SPGX070304MD |

| 材质 | KCU25 |

| [SSC] 刀片 IC 尺寸 | 7.95 mm |

| [SSC] 刀片 IC 尺寸 | 0.313 in |

| [D1] 刀片孔尺寸 | 2.85 mm |

| [D1] 刀片孔尺寸 | 0.112 in |

| [S] 刀片厚度 | 3.18 mm |

| [S] 刀片厚度 | 0.1252 in |

| [Rε] 刀尖半径 | 0.4 mm |

| [Rε] 刀尖半径 | 0.016 in |

| [GAA] 刀片前角 | 16 |

| [主要后角角度] | 7 |

| 第二主要后角 | 11 |

工件材料

- 钢

- 不锈钢

- 铸铁

- 非铁材质

Grades

KCU25

成份:一种高级PVD材质,具有硬质AlTiN涂层,以及细晶粒的非合金基体。这种经过改良的新型涂层可以提高刃口的稳定性,并可用于多种切削速度和进给量的加工。

应用范围:KCU25™ 材质是用于多种钢材料、不锈钢、高温合金、钛、铁,以及非铁金属材料通用加工的理想材质;可采用多种切削速度和进给率进行加工,刃口具有更好的韧性,可进行高进给断续切削加工。

Features and benefits

- Four cutting edges per insert

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

应用数据

| 公制 | |||||||||||||||

| 材料 分组 | 条件 | 刀窝 | 槽型 | 材质 | 切削速度 | 根据直径推荐进给率(fz) | |||||||||

| 范围 | |||||||||||||||

| 最小值 | 初始值 | 最大值 | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| P | 1 | S | O | MD | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 |

| I | MD | KC7140 | |||||||||||||

| U | O | FP | KCU25 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | MD | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | FP | KCU25 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | MD | KCPK10 | 260 | 285 | 320 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | FP | KCU25 | 180 | 195 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 110 | 120 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 4 | S | O | FP | KCPK10 | 220 | 250 | 300 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU25 | 150 | 180 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 90 | 110 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 5 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 6 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 公制 | |||||||||||||||

| 切削速度 | 公制 | ||||||||||||||

| 范围 | 根据直径推荐进给率(fz) | ||||||||||||||

| 材料 分组 | condition | 刀窝 | 槽型 | 材质 | 最小值 | 初始值 | 最大值 | Ø | SPGX05 DFTX2 14,00-17,49 | SPGX06 DFT03 17,50-21,99 | SPGX07 DFT05 22.00-25,99 | SPGX09 DFT05 26.00-32,99 | SPGX12 DFT06/..07 33,00-43,99 | SPGX15 DFT07/..09 44,00-55,00 | |

| P | 1 | S | O | MD | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 |

| 1 | S | I | MD | KC7140 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 1 | U | O | FP | KCU25 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | U | I | MD | KC7140 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | I | I | MD | KC7140 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | S | O | MD | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 2 | S | I | MD | KC7140 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 2 | U | O | FP | KCU25 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | U | I | MD | KC7140 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | I | I | MD | KC7140 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | S | O | MD | KCPK10 | 260 | 285 | 320 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 3 | S | I | MD | KC7140 | 260 | 285 | 320 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 3 | U | O | FP | KCU25 | 180 | 195 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | U | I | MD | KC7140 | 180 | 195 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | I | O | HP | KCU40 | 110 | 120 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | I | I | MD | KC7140 | 110 | 120 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | S | O | FP | KCPK10 | 220 | 250 | 300 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 4 | S | I | MD | KC7140 | 220 | 250 | 300 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 4 | U | O | HP | KCU25 | 150 | 180 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | U | I | MD | KC7140 | 150 | 180 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | I | O | HP | KCU40 | 90 | 110 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | I | I | MD | KC7140 | 90 | 110 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 5 | S | I | MD | KC7140 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 5 | U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | U | I | MD | KC7140 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | I | I | MD | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 6 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 6 | S | I | MD | KC7140 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 6 | U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 6 | U | I | MD | KC7140 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 6 | I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 6 | I | I | MD | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 公制 | |||||||||||||||

| 材料 分组 | 条件 | 刀窝 | 槽型 | 材质 | 切削速度 | 根据直径推荐进给率(fz) | |||||||||

| 范围 | |||||||||||||||

| 最小值 | 初始值 | 最大值 | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| M | 1 | S | O | FP | KCU25 | 150 | 190 | 230 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 |

| I | MD | KC7140 | |||||||||||||

| U | O | MD | KCU40 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | FP | KCU25 | 150 | 180 | 210 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| I | MD | KC7140 | |||||||||||||

| U | O | MD | KCU40 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | HP | KCU25 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| I | HP | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 80 | 110 | 140 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | |||||||||||||

| 公制 | |||||||||||||||

| 切削速度 | |||||||||||||||

| 范围 | 根据直径推荐进给率(fz) | ||||||||||||||

| 材料 分组 | 条件 | 刀窝 | 槽型 | 材质 | 最小值 | 初始值 | 最大值 | Ø | SPGX05 DFTX2 14,00–17,49 | SPGX06 DFT03 17,50–21,99 | SPGX07 DFT05 22.00–25,99 | SPGX09 DFT05 26.00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | |

| M | 1 | S | O | FP | KCU25 | 150 | 190 | 230 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 |

| 1 | S | I | MD | KC7140 | 150 | 190 | 230 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | U | O | MD | KCU40 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 1 | U | I | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 1 | I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 1 | I | I | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 2 | S | O | FP | KCU25 | 150 | 180 | 210 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | S | I | MD | KC7140 | 150 | 180 | 210 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | U | O | MD | KCU40 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 2 | U | I | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 2 | I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 2 | I | I | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 3 | S | O | HP | KCU25 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | S | I | HP | KC7140 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | U | O | HP | KCU40 | 80 | 110 | 140 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 3 | U | I | HP | KC7140 | 80 | 110 | 140 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 3 | I | O | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 3 | I | I | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 公制 | |||||||||||||||

| 材料 分组 | 条件 | 刀窝 | 槽型 | 材质 | 切削速度 | 根据直径推荐进给率(fz) | |||||||||

| 范围 | |||||||||||||||

| 最小值 | 初始值 | 最大值 | Ø | ||||||||||||

| N | 1 | S | O | LP | KCU40 | 150 | 190 | 230 | mm/r | 0,06-0,08 | 0,06-0,10 | 0,08-0,12 | 0,10-0,16 | 0,12-0,021 | 0,14-0,024 |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/r | 0,05-0,07 | 0,06-0,08 | 0,07-0,10 | 0,05-0,10 | 0,06-0,013 | 0,08-0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 2 | S | O | LP | KCU40 | 150 | 180 | 210 | mm/r | 0,06–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,16 | 0,12–0,021 | 0,14–0,024 | |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/r | 0,05-0,07 | 0,06-0,08 | 0,07-0,10 | 0,05-0,10 | 0,06-0,013 | 0,08-0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 3 | S | O | LP | KCU40 | 150 | 190 | 230 | mm/r | 0,06-0,08 | 0,06-0,10 | 0,08-0,12 | 0,10-0,16 | 0,12-0,021 | 0,14-0,024 | |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/r | 0,05-0,07 | 0,06-0,08 | 0,07-0,10 | 0,05-0,10 | 0,06-0,013 | 0,08-0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 公制 | |||||||||||||||

| 切削速度 | |||||||||||||||

| 范围 | 根据直径推荐进给率(fz) | ||||||||||||||

| 材料 分组 | 条件 | 刀窝 | 槽型 | 材质 | 最小值 | 初始值 | 最大值 | Ø | SPGX05 DFTX2 14,00–17,49 | SPGX06 DFT03 17,50–21,99 | SPGX07 DFT05 22.00–25,99 | SPGX09 DFT05 26.00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | |

| K | 1 | S | O | FP | KCPK10 | 200 | 240 | 300 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 |

| 1 | S | I | HP | KCU40 | 200 | 240 | 300 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 1 | U | O | FP | KCU25 | 120 | 155 | 200 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | U | I | HP | KC7140 | 120 | 155 | 200 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | I | O | FP | KC7140 | 80 | 100 | 125 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | I | I | HP | KC7140 | 80 | 100 | 125 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | S | O | FP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 2 | S | I | HP | KCU40 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 2 | U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | U | I | HP | KC7140 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | I | O | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | I | I | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | S | O | HP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 3 | S | I | HP | KCU40 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 3 | U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | U | I | HP | KC7140 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | I | O | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | I | I | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 公制 | |||||||||||||||

| 材料 分组 | 条件 | 刀窝 | 槽型 | 材质 | 切削速度 | 根据直径推荐进给率(fz) | |||||||||

| 范围 | |||||||||||||||

| 最小值 | 初始值 | 最大值 | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| K | 1 | S | O | FP | KCPK10 | 200 | 240 | 300 | 毫米/转 | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 |

| I | HP | KCU40 | |||||||||||||

| U | O | FP | KCU25 | 120 | 155 | 200 | 毫米/转 | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | FP | KC7140 | 80 | 100 | 125 | 毫米/转 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | HP | KC7140 | |||||||||||||

| 2 | S | O | FP | KCPK10 | 180 | 220 | 260 | 毫米/转 | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 110 | 140 | 170 | 毫米/转 | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 80 | 100 | 120 | 毫米/转 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | HP | KC7140 | |||||||||||||

| 3 | S | O | HP | KCPK10 | 180 | 220 | 260 | 毫米/转 | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 110 | 140 | 170 | 毫米/转 | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 80 | 100 | 120 | 毫米/转 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | HP | KC7140 | |||||||||||||

| N | 1 | S | O | LP | KCU40 | 150 | 190 | 230 | 毫米/转 | 0,06–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,16 | 0,12–0,021 | 0,14–0,024 |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | 毫米/转 | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | 毫米/转 | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 2 | S | O | LP | KCU40 | 150 | 180 | 210 | 毫米/转 | 0,06–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,16 | 0,12–0,021 | 0,14–0,024 | |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | 毫米/转 | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | 毫米/转 | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 3 | S | O | LP | KCU40 | 150 | 190 | 230 | 毫米/转 | 0,06–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,16 | 0,12–0,021 | 0,14–0,024 | |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | 毫米/转 | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | 毫米/转 | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 公制 | |||||||||||||||

| 切削速度 | |||||||||||||||

| 范围 | 根据直径推荐进给率(fz) | ||||||||||||||

| 材料 分组 | 条件 | 刀窝 | 槽型 | 材质 | 最小值 | 初始值 | 最大值 | Ø | SPGX05 DFTX2 14,00–17,49 | SPGX06 DFT03 17,50–21,99 | SPGX07 DFT05 22.00–25,99 | SPGX09 DFT05 26.00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | |

| N | 1 | S | O | HP | KCPK10 | 350 | 500 | 650 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 |

| 1 | S | I | HP | KMF | 350 | 500 | 650 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 1 | U | O | HP | KCU40 | 300 | 400 | 500 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | U | I | HP | KMF | 300 | 400 | 500 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | I | O | HP | KCU40 | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | I | I | HP | KMF | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | S | O | HP | KCPK10 | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 2 | S | I | HP | KMF | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 2 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | U | I | HP | KMF | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | I | O | HP | KCU40 | 175 | 250 | 325 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | I | I | HP | KMF | 175 | 250 | 325 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | S | O | HP | KCPK10 | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 3 | S | I | HP | KMF | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 3 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | U | I | HP | KMF | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | I | O | HP | KCU40 | 150 | 250 | 350 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | I | I | HP | KMF | 150 | 250 | 350 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | S | O | HP | KCU25 | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 4 | S | I | HP | KC7140 | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 4 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 4 | U | I | HP | KC7140 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 4 | I | O | HP | KCU40 | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | I | I | HP | KC7140 | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | S | O | HP | KCU40 | 400 | 450 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 5 | S | I | HP | KMF | 400 | 450 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 5 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 5 | U | I | HP | KMF | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 5 | I | O | HP | KCU40 | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | I | I | HP | KMF | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 公制 | |||||||||||||||

| 材料 分组 | 条件 | 刀窝 | 槽型 | 材质 | 切削速度 | 根据直径推荐进给率(fz) | |||||||||

| 范围 | |||||||||||||||

| 最小值 | 初始值 | 最大值 | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| S | 1 | S | O | HP | KCU40 | 60 | 70 | 75 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 40 | 50 | 60 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| 4 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| 公制 | |||||||||||||||

| 切削速度 | |||||||||||||||

| 范围 | 根据直径推荐进给率(fz) | ||||||||||||||

| 材料 分组 | 条件 | 刀窝 | 槽型 | 材质 | 最小值 | 初始值 | 最大值 | Ø | SPGX05 DFTX2 14,00–17,49 | SPGX06 DFT03 17,50–21,99 | SPGX07 DFT05 22.00–25,99 | SPGX09 DFT05 26.00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | |

| S | 1 | S | O | HP | KCU40 | 60 | 70 | 75 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 |

| 1 | S | I | MD | KC7140 | 60 | 70 | 75 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 1 | U | O | HP | KCU40 | 40 | 50 | 60 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 1 | U | I | MD | KC7140 | 40 | 50 | 60 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 1 | I | O | HP | KCU40 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 1 | I | I | MD | KC7140 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 2 | S | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 2 | S | I | MD | KC7140 | 50 | 60 | 70 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 2 | U | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 2 | U | I | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 2 | I | O | HP | KCU40 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 2 | I | I | MD | KC7140 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 3 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 3 | S | I | MD | KC7140 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 3 | U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 3 | U | I | MD | KC7140 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 3 | I | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 3 | I | I | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 4 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 4 | S | I | MD | KC7140 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 4 | U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 4 | U | I | MD | KC7140 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 4 | I | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 4 | I | I | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

I have read and accepted the Terms & Conditions of use