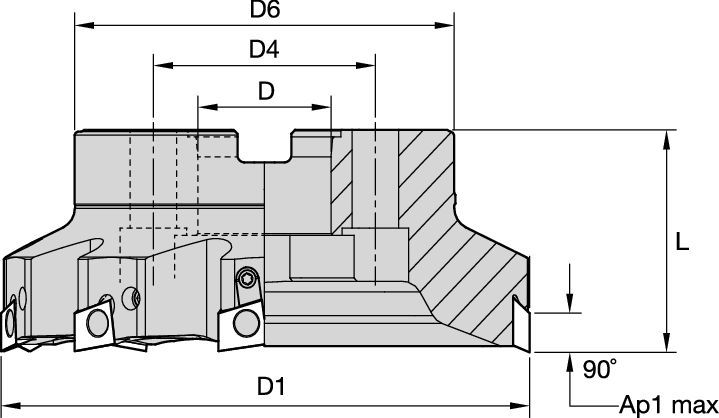

Fix-Perfect™ 90° • 铝材料 • 套式铣刀 • PM 系列 • 公制

套式铣刀 • PM 系列

物料号1758496

公制样本编号100B06RP90BG15C2WPM英制样本编号100B06RP90BG15C2WPM

- P 钢

- K 铸铁

- N 非铁材质

- H 淬火材料

- .caption

端面铣削

侧铣/方肩铣削: 方头立铣

铣削 — 贯通式冷却

铣削 — 侧铣和端面铣

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 1758496 |

| 公制样本编号 | 100B06RP90BG15C2WPM |

| 英制样本编号 | 100B06RP90BG15C2WPM |

| [D1] 有效的切削直径 | 100 mm |

| [D1] 有效的切削直径 | 3.937 in |

| [D]适配接头/刀柄/镗孔直径 | 32 mm |

| [D]适配接头/刀柄/镗孔直径 | 1.2598 in |

| [D6] 保护区孔直径 | 84 mm |

| [D6] 保护区孔直径 | 3.3071 in |

| [L] 总长 | 50 mm |

| [L] 总长 | 1.9685 in |

| [AP1MAX] 第一个最大切深 | 9.5 mm |

| [AP1MAX] 第一个最大切深 | 0.374 in |

| 刀片数量 | 6 |

| 可调刀片数量 | 2 |

| 重量(千克) | 1.68 |

| 最大 RPM | 12732 |

工件材料

- 钢

- 铸铁

- 非铁材质

- 淬火材料

- .caption

Uses and application

端面铣削

侧铣/方肩铣削: 方头立铣

铣削 — 贯通式冷却

铣削 — 侧铣和端面铣

Features and benefits

- 加工工件具有极佳的表面精度和平面度。

- 固定式及可调式刀窝。

- 用于高速加工。

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

Feeds

推荐初始进给率 [mm]

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| BGHX… | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,16 | 0,27 | 0,05 | 0,15 | 0,25 | BGHX… |

| 轻切削 | 中等切削 | 重切削 |

Speeds

推荐初始速度 [m/min]

| 材料 分组 | K110M | KC510M | KD1410 | KD1415 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | 505 | 475 | 450 | 640 | 570 | 525 | 4010 | 3505 | 2990 | 4010 | 3505 | 2990 |

| 3 | 410 | 365 | 320 | 580 | 535 | 490 | 1600 | 1495 | 1400 | 1600 | 1495 | 1400 | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

High Performance Combination Tools

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| (锋利的槽型) | – | (强壮的槽型) | ||||

| 耐磨性 |  | 韧性 | ||||

| 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | BGHX… | K110M | BGHX… | KC510M | BGHX… | KD1415 |

| N3 | BGHX… | K110M | BGHX… | KD1410 | BGHX… | KD1410 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use