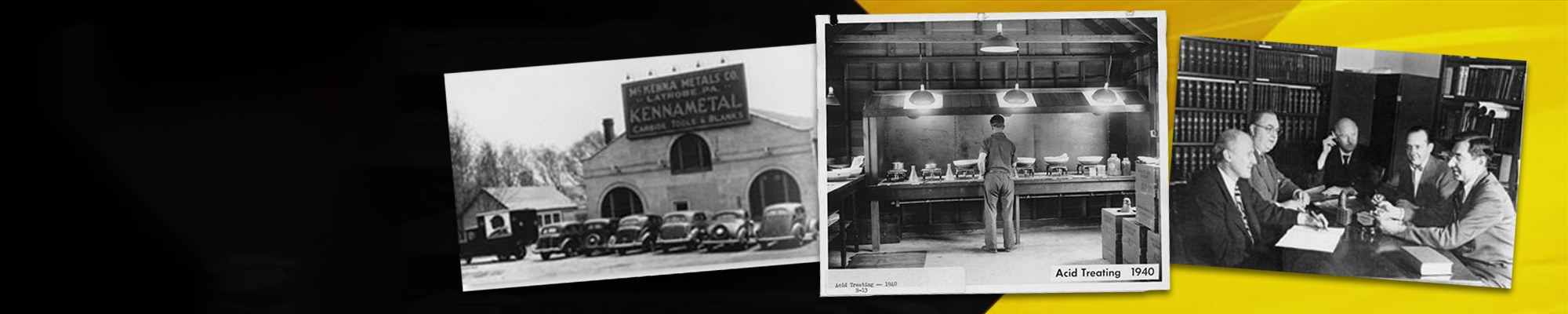

A Pioneer in Materials Science

Breaking barriers in materials science is what we do. This mission started 85 years ago with our founder, metallurgist Philip M. McKenna, and it has continued ever since. After years of research, McKenna created a tungsten-titanium carbide alloy that provided a productivity breakthrough in the machining of steel. With McKenna’s innovation, Kennametal tools cut faster and lasted longer than the competition, enabling customers across industries – from transportation to aerospace – to machine metal at rates never seen before.