Premium Wear Protection for Over 30 Years

Providing high-end wear protection for directional drilling components since 1985, Conforma Clad™ proprietary tungsten carbide brazing technology offers exceptional wear protection for downhole and surface equipment, including mud motor radial bearings and flow diverters.

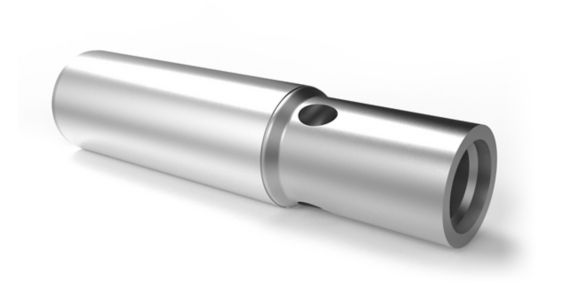

Mud Motor Radial Bearings

Radial bearings are a key component of downhole oil and gas drilling operations, transmitting radial loads from the bit through the drill string.

With Kennametal Conforma Clad bearings, contractors can push mud motors harder and get the job done faster. Easily handling extreme side loading , enabling sharper turns and increasing drill accuracy, our bearings reduce downtime and increase drill productivity.