Forestry Experience

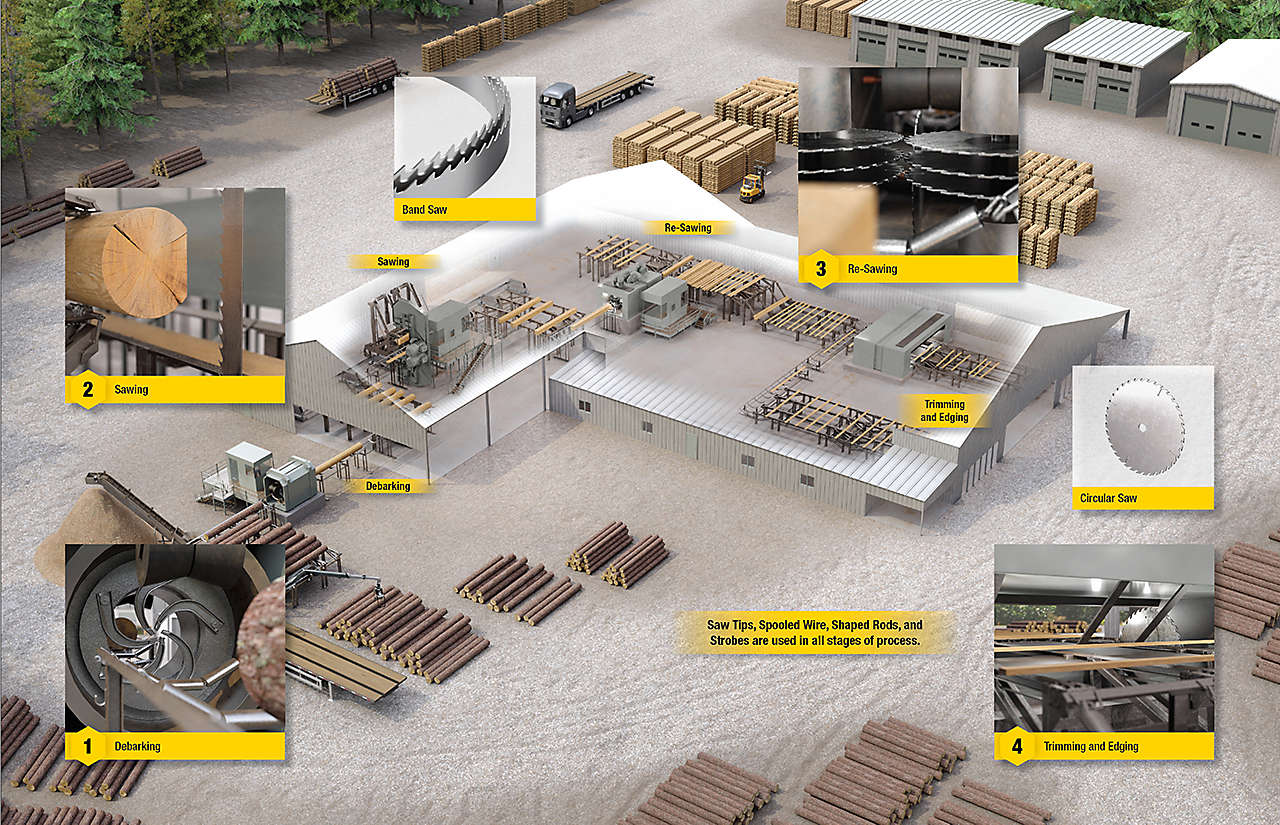

Kennametal uses a collaborative approach to deliver an extensive saw tipping portfolio that best fits our partners’ needs. Our knowledge and understanding of the timber industry leads to continually enhanced products and improved service. Our partnerships with lumber mills, distributors, and equipment manufacturers facilitate ease of business, product availability, and breadth of portfolio.

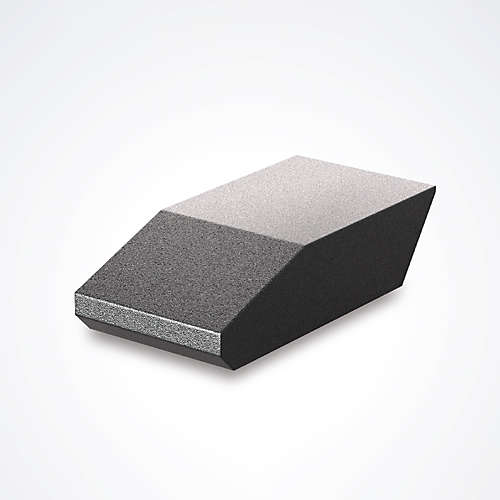

Quality

Our tungsten carbide and Stellite materials are produced to the highest quality standards, ensuring saw sharpness and tip strength are never compromised. Our dedication to quality means reliable performance, longer run times, and no surprises.

Consistency

Kennametal offers a wide selection of sawmilling solutions to provide its users with consistent results even in the most inconsistent environments and with toughest species of wood.