1. Versatility

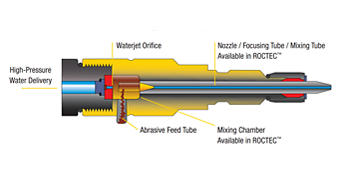

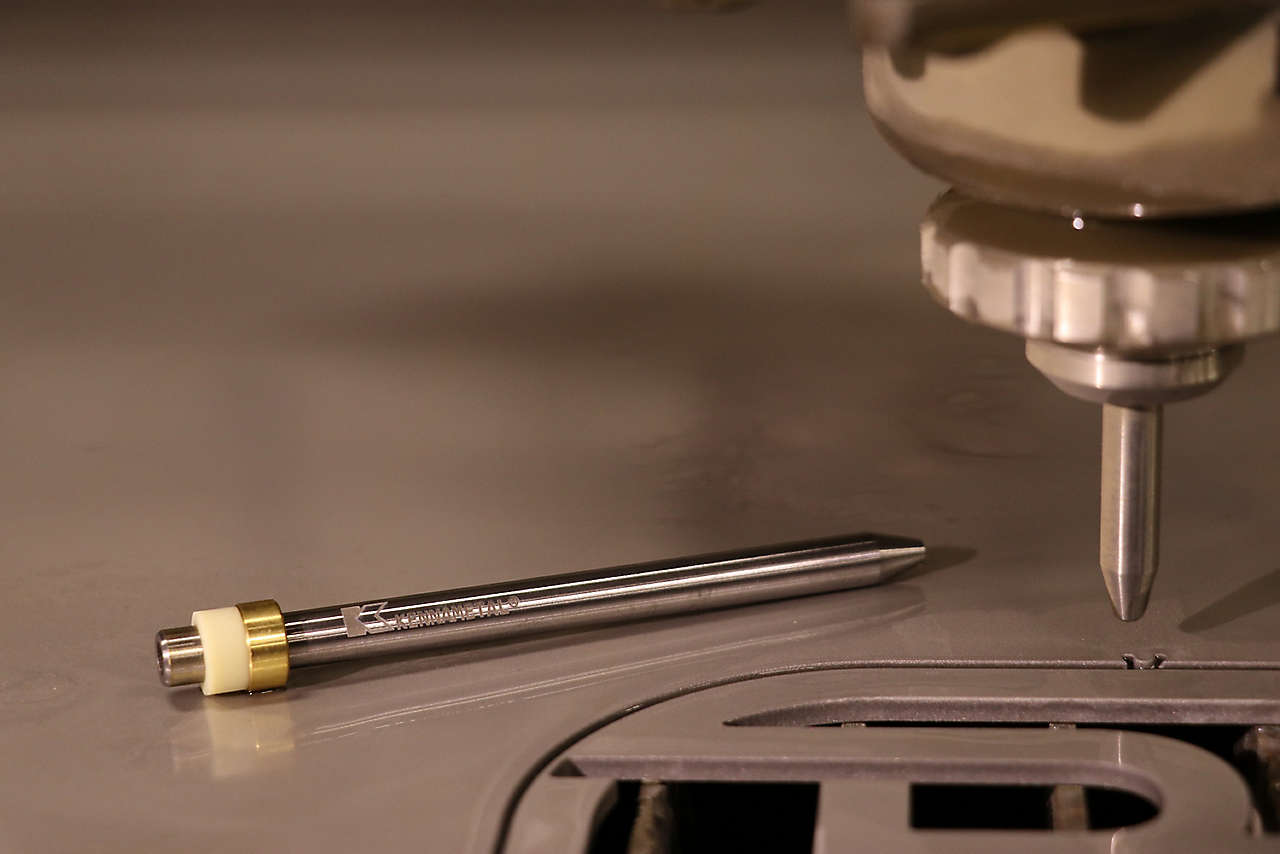

Kennametal’s product is the last thing that customer’s abrasive jet stream touches before hitting the workpiece, so it is very critical. Abrasive waterjet cutting is used on a variety of workpiece materials, so customers need a versatile product offering that can be adapted for numerous materials. Some of the primary materials that ROCTEC customers are cutting include metals, composites, ceramics, exotic alloys, and even stone. In addition to the different materials, there are many varying machine settings for the process including pump pressures, abrasive feed rates, cutting head configurations and many more. ROCTEC provides a premium high-performance offering to address the varying cutting operations in practice today.