欢迎

请确认您的首选项

更新首选项

产品建议

Product Family suggestions

编辑解决方案

添加解决方案

解决方案名称: {{SolutionName}}- 产品

- /

- Mill 1-10™ Helical End Mills • Screw-On • Inch

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

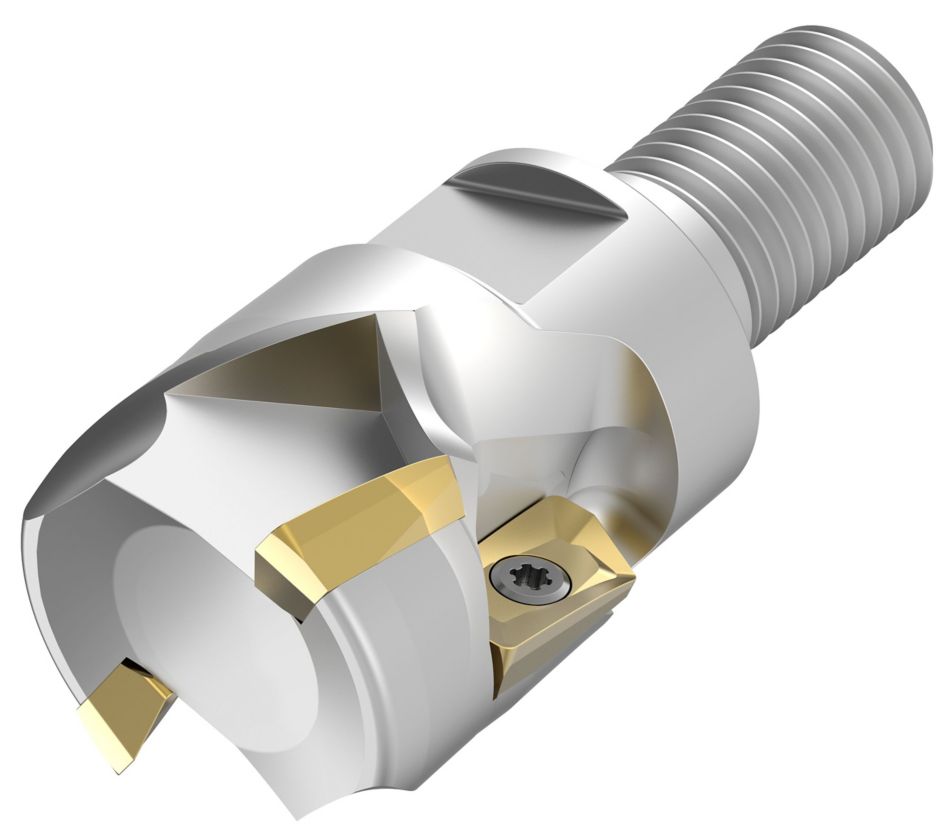

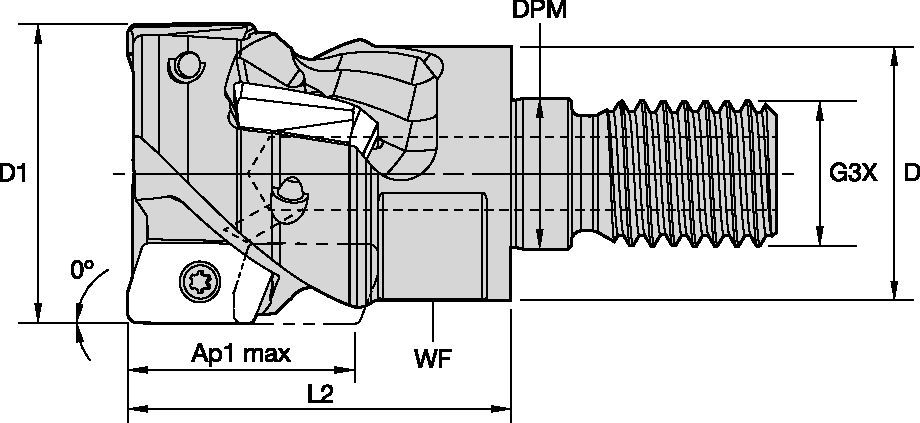

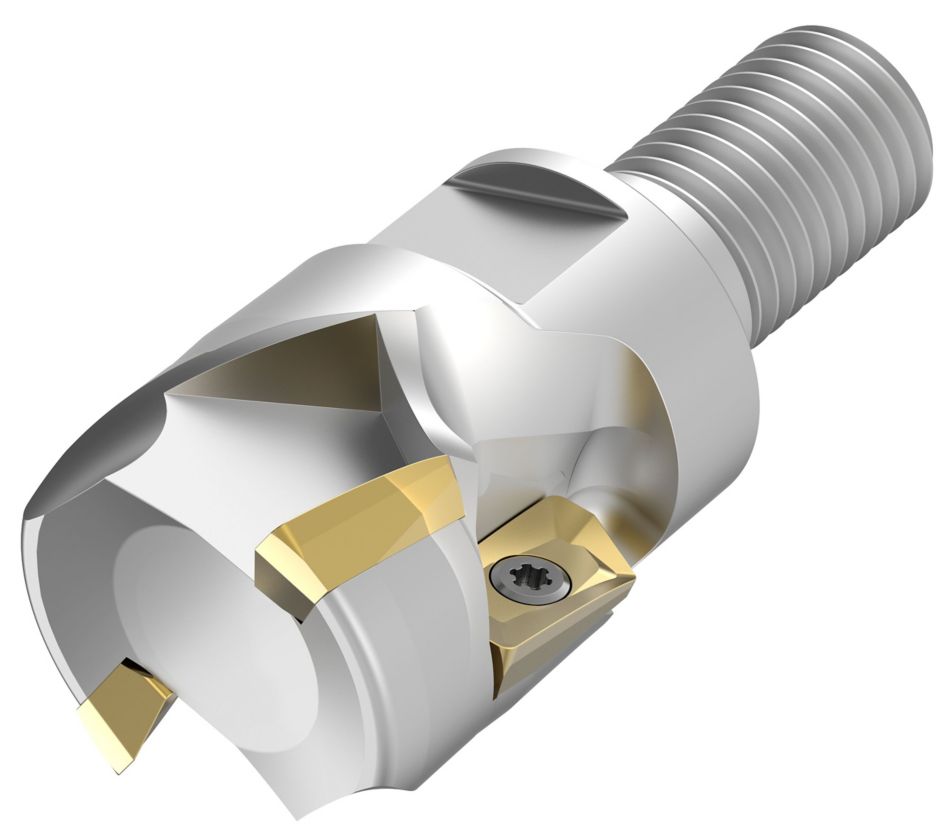

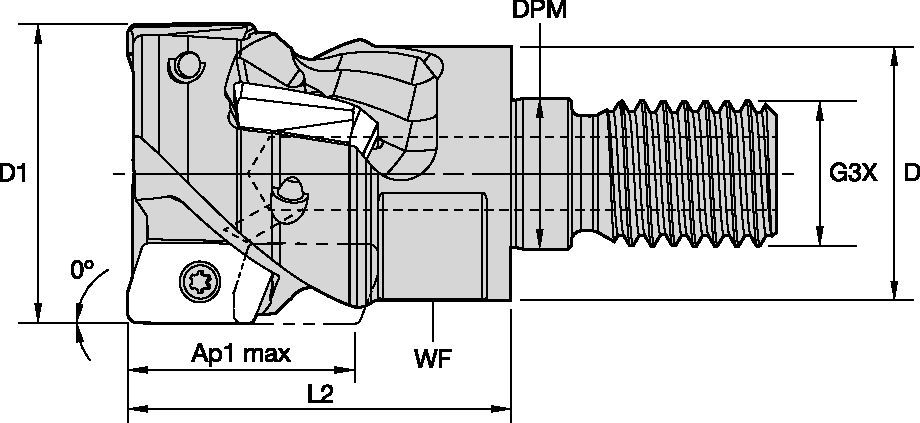

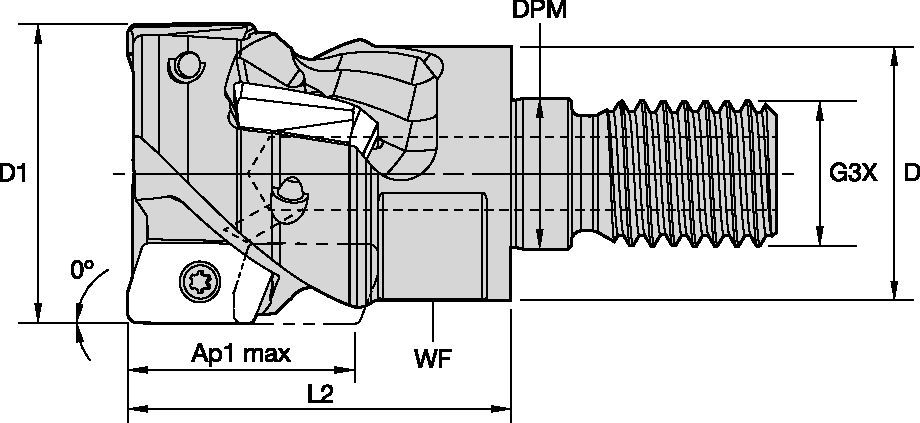

Mill 1-10™ Helical End Mills • Screw-On • Inch

Indexable Helical End Mills

Features and benefits

- 可进行 90°壁面铣削加工。

- 极佳的坡铣性能。

- 卓越的表面精加工性能。

Uses and application

端面铣削

螺旋铣削

坡铣: 毛坯

槽铣: 方头立铣

侧铣/方肩铣削: 方头立铣

刀柄 — 旋入式

铣削 — 贯通式冷却

刀座

刀片选择指南

| Material

|

Light

|

Medium

|

Heavy

|

|||

| P1–P2 | .E..LD | KCPM40 | .S..GD | KCPM40 | .E..HD | KCPM40 |

| P3–P4 | .E..LD | KCPK30 | .S..GD | KCPK30 | .E..HD | KCPK30 |

| P5–P6 | .E..LD | KC725M | .S..GD | KC725M | .E..HD | KC725M |

| M1–M2 | .E..LD | KCSM40 | .S..GD | KC725M | .E..HD | KCSM40 |

| M3 | .E..LD | KCSM40 | .S..GD | KCPM40 | .E..HD | KCSM40 |

| K1–K2 | .E..LD | KCK15 | .S..GD | KCK15 | .E..HD | KCK15 |

| K3 | .E..LD | KCK20B | .S..GD | KCK20B | .E..HD | KCK20B |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC422M | .E..LDJ | KC422M |

| N3 | .F..LDJ | KC410M | .E..LDJ | KC422M | .E..LDJ | KC422M |

| S1–S2 | .E..LD | KC725M | .S..GD | KC725M | .E..HD | KC725M |

| S3 | .E..LD | KCSM40 | .S..GE | KCSM40 | .E..HD | KCSM40 |

| S4 | .E..LD | KCSM40 | .S..GE | KCSM40 | .E..HD | KCSM40 |

| H1 | .E..LD | KC510M | – | – | – | – |

推荐初始进给率 [mm]

| Light

|

General

|

Heavy

|

| Mill 1-10™ • Recommended Starting Feeds [mm] | |||||||||||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .F..LDJ | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,16 | 0,27 | 0,05 | 0,15 | 0,25 |

| .F..-PCD | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,16 | 0,27 | 0,05 | 0,15 | 0,25 |

| .E..LDJ | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,32 | 0,06 | 0,16 | 0,28 | 0,05 | 0,15 | 0,25 |

| .E..LD | 0,12 | 0,35 | 0,57 | 0,09 | 0,25 | 0,41 | 0,07 | 0,19 | 0,31 | 0,06 | 0,17 | 0,27 | 0,05 | 0,15 | 0,25 |

| .S..GE | 0,23 | 0,46 | 0,70 | 0,17 | 0,33 | 0,51 | 0,13 | 0,25 | 0,38 | 0,11 | 0,22 | 0,33 | 0,10 | 0,20 | 0,30 |

| .S..GD | 0,23 | 0,47 | 0,71 | 0,17 | 0,34 | 0,51 | 0,13 | 0,25 | 0,38 | 0,11 | 0,22 | 0,33 | 0,10 | 0,20 | 0,30 |

| .E..HD | 0,23 | 0,51 | 0,82 | 0,17 | 0,37 | 0,59 | 0,13 | 0,28 | 0,44 | 0,11 | 0,24 | 0,38 | 0,10 | 0,22 | 0,35 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||||||||||

| Mill 1-10™ • Recommended Starting Feeds [IPT] | |||||||||||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .F..LDJ | 0.005 | 0.014 | 0.023 | 0.003 | 0.010 | 0.017 | 0.003 | 0.008 | 0.013 | 0.002 | 0.007 | 0.011 | 0.002 | 0.006 | 0.010 |

| .F..-PCD | 0.005 | 0.014 | 0.023 | 0.003 | 0.010 | 0.017 | 0.003 | 0.008 | 0.013 | 0.002 | 0.007 | 0.011 | 0.002 | 0.006 | 0.010 |

| .E..LDJ | 0.005 | 0.014 | 0.023 | 0.003 | 0.010 | 0.017 | 0.003 | 0.008 | 0.013 | 0.002 | 0.007 | 0.011 | 0.002 | 0.006 | 0.010 |

| .E..LD | 0.005 | 0.014 | 0.023 | 0.004 | 0.010 | 0.016 | 0.003 | 0.008 | 0.012 | 0.002 | 0.007 | 0.011 | 0.002 | 0.006 | 0.010 |

| .S..GE | 0.009 | 0.018 | 0.028 | 0.007 | 0.013 | 0.020 | 0.005 | 0.010 | 0.015 | 0.004 | 0.009 | 0.013 | 0.004 | 0.008 | 0.012 |

| .S..GD | 0.009 | 0.019 | 0.028 | 0.007 | 0.013 | 0.020 | 0.005 | 0.010 | 0.015 | 0.004 | 0.009 | 0.013 | 0.004 | 0.008 | 0.012 |

| .E..HD | 0.009 | 0.020 | 0.032 | 0.007 | 0.014 | 0.023 | 0.005 | 0.011 | 0.017 | 0.004 | 0.009 | 0.015 | 0.004 | 0.009 | 0.014 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||||||||||

| Light

|

General

|

Heavy

|

推荐初始速度 [m/min]

| Mill 1-10™ • Recommended Starting Speed [m/min] | ||||||||||||||||||||||||||||||||||||||||||||

| D = Dry Machining W = Wet Machining Y = Yes N = No Y, -20% = Yes, but reduce speed by 20% | K313 | KC410M | KC422M | KC510M | KC522M | KC725M | KCK15 | KCK20B | KCKP10 | KCPK30 | KCPM40 | KCSM30 | KCSM40 | KD1410 | ||||||||||||||||||||||||||||||

| Chip Thickness hex mm | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||||||||||

| D | W | Cutting Speed (m/min) | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min |

| P | ||||||||||||||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 330 | 285 | 270 | 260 | 230 | 215 | – | – | – | – | – | – | 300 | 295 | 260 | 455 | 395 | 370 | 295 | 260 | 245 | 370 | 320 | 300 | 350 | 320 | 300 | – | – | – |

| Y | Y, -20% | 2 | – | – | – | – | – | – | – | – | – | – | – | – | 275 | 240 | 200 | 220 | 190 | 160 | – | – | – | – | – | – | 310 | 275 | 240 | 280 | 255 | 230 | 250 | 215 | 180 | 305 | 270 | 220 | 300 | 270 | 220 | – | – | – |

| Y | Y, -20% | 3 | – | – | – | – | – | – | – | – | – | – | – | – | 255 | 215 | 175 | 200 | 170 | 140 | – | – | – | – | – | – | 275 | 240 | 205 | 255 | 230 | 205 | 230 | 195 | 160 | 285 | 240 | 195 | 280 | 240 | 195 | – | – | – |

| Y | Y, -20% | 4 | – | – | – | – | – | – | – | – | – | 245 | 200 | 170 | 225 | 185 | 150 | 180 | 150 | 120 | – | – | – | – | – | – | 240 | 205 | 160 | 225 | 185 | 160 | 205 | 170 | 135 | 250 | 205 | 165 | 240 | 205 | 165 | – | – | – |

| Y | Y, -20% | 5 | – | – | – | – | – | – | – | – | – | – | – | – | 185 | 170 | 150 | 150 | 135 | 120 | – | – | – | – | – | – | 205 | 160 | 125 | 190 | 170 | 150 | 170 | 155 | 135 | 205 | 190 | 165 | 200 | 180 | 160 | – | – | – |

| Y | Y, -20% | 6 | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 125 | 100 | 130 | 100 | 80 | – | – | – | – | – | – | 160 | 125 | 110 | 160 | 135 | 110 | 150 | 115 | 90 | 185 | 140 | 110 | 180 | 140 | 100 | – | – | – |

| M | ||||||||||||||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 205 | 180 | 165 | 170 | 150 | 135 | – | – | – | – | – | – | – | – | – | 205 | 185 | 155 | 195 | 170 | 155 | 225 | 180 | 170 | 260 | 210 | 185 | – | – | – |

| Y | Y, -20% | 2 | – | – | – | – | – | – | – | – | – | – | – | – | 185 | 160 | 130 | 155 | 130 | 110 | – | – | – | – | – | – | – | – | – | 185 | 160 | 140 | 175 | 150 | 125 | 205 | 160 | 135 | 235 | 180 | 145 | – | – | – |

| Y | Y, -20% | 3 | – | – | – | – | – | – | – | – | – | – | – | – | 140 | 120 | 95 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | 145 | 130 | 115 | 130 | 115 | 90 | 155 | 125 | 95 | 175 | 145 | 110 | – | – | – |

| K | ||||||||||||||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | 160 | 140 | 120 | – | – | – | – | – | – | 295 | 265 | 240 | 230 | 205 | 185 | – | – | – | 420 | 385 | 340 | 360 | 290 | 245 | 410 | 330 | 240 | 295 | 265 | 240 | – | – | – | – | – | – | – | – | – | – | – | – |

| Y | Y, -20% | 2 | 140 | 120 | 100 | – | – | – | – | – | – | 230 | 205 | 190 | 180 | 160 | 150 | – | – | – | 335 | 295 | 275 | 280 | 230 | 195 | 280 | 245 | 190 | 235 | 210 | 190 | – | – | – | – | – | – | – | – | – | – | – | – |

| Y | Y, -20% | 3 | 125 | 105 | 85 | – | – | – | – | – | – | 195 | 175 | 160 | 150 | 135 | 120 | – | – | – | 280 | 250 | 230 | 210 | 175 | 140 | 240 | 195 | 160 | 195 | 175 | 160 | – | – | – | – | – | – | – | – | – | – | – | – |

| N | ||||||||||||||||||||||||||||||||||||||||||||

| N | Y | 1 | 795 | 695 | 600 | 1215 | 1080 | 995 | 1075 | 945 | 875 | 640 | 570 | 525 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 3850 | 3365 | 2870 |

| N | Y | 2 | 615 | 520 | 425 | 1080 | 995 | 915 | 945 | 875 | 760 | 580 | 535 | 490 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1535 | 1435 | 1340 |

| N | Y | 3 | 615 | 520 | 425 | 1080 | 995 | 915 | 945 | 875 | 760 | 580 | 535 | 490 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1535 | 1435 | 1340 |

| S | ||||||||||||||||||||||||||||||||||||||||||||

| N | Y | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | 50 | 40 | 25 | – | – | – |

| N | Y | 2 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | 55 | 40 | 25 | – | – | – |

| N | Y | 3 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 25 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | 55 | 45 | 30 | 65 | 45 | 30 | – | – | – |

| N | Y | 4 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 45 | 35 | 50 | 45 | 30 | – | – | – | – | – | – | – | – | – | 50 | 45 | 35 | 55 | 50 | 35 | 60 | 55 | 40 | 75 | 60 | 40 | – | – | – |

| H | ||||||||||||||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | – | – | – | 130 | 105 | 80 | 120 | 90 | 70 | – | – | – | – | – | – | – | – | – | 140 | 110 | 90 | – | – | – | – | – | – | 135 | 100 | 75 | – | – | – | – | – | – |

| Y | Y, -20% | 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Y | Y, -20% | 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||||||||||||||||||||||||

Recommended Starting Speeds [SFM]

| Mill 1-10™ • Recommended Starting Speeds [SFM] | ||||||||||||||||||||||||||||||||||||||||||||

| D = Dry Machining W = Wet Machining Y = Yes N = No Y, -20% = Yes, but reduce speed by 20% | K313 | KC410M | KC422M | KC510M | KC522M | KC725M | KCK15 | KCK20B | KCKP10 | KCPK30 | KCPM40 | KCSM30 | KCSM40 | KD1410 | ||||||||||||||||||||||||||||||

| Chip Thickness hex Inch | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||||||||||

| D | W | Cutting Speed

|

Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min | Start | Start | Min |

| P | ||||||||||||||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 1085 | 935 | 885 | 855 | 755 | 705 | – | – | – | – | – | – | 985 | 970 | 855 | 1495 | 1295 | 1215 | 970 | 855 | 805 | 1215 | 1050 | 985 | 1150 | 1050 | 985 | – | – | – |

| Y | Y, -20% | 2 | – | – | – | – | – | – | – | – | – | – | – | – | 900 | 785 | 655 | 720 | 625 | 525 | – | – | – | – | – | – | 1015 | 900 | 785 | 920 | 835 | 755 | 820 | 705 | 590 | 1000 | 885 | 720 | 985 | 885 | 720 | – | – | – |

| Y | Y, -20% | 3 | – | – | – | – | – | – | – | – | – | – | – | – | 835 | 705 | 575 | 655 | 560 | 460 | – | – | – | – | – | – | 900 | 785 | 675 | 835 | 755 | 675 | 755 | 640 | 525 | 935 | 785 | 640 | 920 | 785 | 640 | – | – | – |

| Y | Y, -20% | 4 | – | – | – | – | – | – | – | – | – | 805 | 655 | 560 | 740 | 605 | 490 | 590 | 490 | 395 | – | – | – | – | – | – | 785 | 675 | 525 | 740 | 605 | 525 | 675 | 560 | 445 | 820 | 675 | 540 | 785 | 675 | 540 | – | – | – |

| Y | Y, -20% | 5 | – | – | – | – | – | – | – | – | – | – | – | – | 605 | 560 | 490 | 490 | 445 | 395 | – | – | – | – | – | – | 675 | 525 | 410 | 625 | 560 | 490 | 560 | 510 | 445 | 675 | 625 | 540 | 655 | 590 | 525 | – | – | – |

| Y | Y, -20% | 6 | – | – | – | – | – | – | – | – | – | – | – | – | 540 | 410 | 330 | 425 | 330 | 260 | – | – | – | – | – | – | 525 | 410 | 360 | 525 | 445 | 360 | 490 | 375 | 295 | 605 | 460 | 360 | 590 | 460 | 330 | – | – | – |

| M | ||||||||||||||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 675 | 590 | 540 | 560 | 490 | 445 | – | – | – | – | – | – | – | – | – | 675 | 605 | 510 | 640 | 560 | 510 | 740 | 590 | 560 | 855 | 690 | 605 | – | – | – |

| Y | Y, -20% | 2 | – | – | – | – | – | – | – | – | – | – | – | – | 605 | 525 | 425 | 510 | 425 | 360 | – | – | – | – | – | – | – | – | – | 605 | 525 | 460 | 575 | 490 | 410 | 675 | 525 | 445 | 770 | 590 | 475 | – | – | – |

| Y | Y, -20% | 3 | – | – | – | – | – | – | – | – | – | – | – | – | 460 | 395 | 310 | 375 | 330 | 260 | – | – | – | – | – | – | – | – | – | 475 | 425 | 375 | 425 | 375 | 295 | 510 | 410 | 310 | 575 | 475 | 360 | – | – | – |

| K | ||||||||||||||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | 525 | 460 | 395 | – | – | – | – | – | – | 970 | 870 | 785 | 755 | 675 | 605 | – | – | – | 1380 | 1265 | 1115 | 1180 | 950 | 805 | 1345 | 1085 | 785 | 970 | 870 | 785 | – | – | – | – | – | – | – | – | – | – | – | – |

| Y | Y, -20% | 2 | 460 | 395 | 330 | – | – | – | – | – | – | 755 | 675 | 625 | 590 | 525 | 490 | – | – | – | 1100 | 970 | 900 | 920 | 755 | 640 | 920 | 805 | 625 | 770 | 690 | 625 | – | – | – | – | – | – | – | – | – | – | – | – |

| Y | Y, -20% | 3 | 410 | 345 | 280 | – | – | – | – | – | – | 640 | 575 | 525 | 490 | 445 | 395 | – | – | – | 920 | 820 | 755 | 690 | 575 | 460 | 785 | 640 | 525 | 640 | 575 | 525 | – | – | – | – | – | – | – | – | – | – | – | – |

| N | ||||||||||||||||||||||||||||||||||||||||||||

| N | Y | 1 | 2610 | 2280 | 1970 | 3985 | 3545 | 3265 | 3525 | 3100 | 2870 | 2100 | 1870 | 1725 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 12630 | 11040 | 9415 |

| N | Y | 2 | 2020 | 1705 | 1395 | 3545 | 3265 | 3000 | 3100 | 2870 | 2495 | 1905 | 1755 | 1610 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 5035 | 4710 | 4395 |

| N | Y | 3 | 2020 | 1705 | 1395 | 3545 | 3265 | 3000 | 3100 | 2870 | 2495 | 1905 | 1755 | 1610 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 5035 | 4710 | 4395 |

| S | ||||||||||||||||||||||||||||||||||||||||||||

| N | Y | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 150 | 130 | 100 | 165 | 130 | 80 | – | – | – |

| N | Y | 2 | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 150 | 130 | 100 | 180 | 130 | 80 | – | – | – |

| N | Y | 3 | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 130 | 80 | 150 | 115 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 130 | 100 | 180 | 150 | 100 | 215 | 150 | 100 | – | – | – |

| N | Y | 4 | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 150 | 115 | 165 | 150 | 100 | – | – | – | – | – | – | – | – | – | 165 | 150 | 115 | 180 | 165 | 115 | 195 | 180 | 130 | 245 | 195 | 130 | – | – | – |

| H | ||||||||||||||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | – | – | – | 425 | 345 | 260 | 395 | 295 | 230 | – | – | – | – | – | – | – | – | – | 460 | 360 | 295 | – | – | – | – | – | – | 445 | 330 | 245 | – | – | – | – | – | – |

| Y | Y, -20% | 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Y | Y, -20% | 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||||||||||||||||||||||||

应用举例

| Mill 1-10™ • Ramping Angles [mm] | ||||||

| insert style | cutting diameter | max ramp angle to non-cutting corner tangent | max ramp angle to steel body interference | DH min [mm] - (min hole diameter) | DH max [mm] - (max hole diameter) | DHI [mm] - (max flat-bottomed hole diameter) |

| Mill-1, 10mm | 12 | not recommended | not recommended | not recommended | not recommended | not recommended |

| Mill-1, 10mm | 16 | 9,7° | 12,3° | 19,50 | 32 | 28,73 |

| Mill-1, 10mm | 18 | 7,6° | 9,6° | 23,29 | 63 | 32,68 |

| Mill-1, 10mm | 20 | 6,2° | 8,6° | 27,25 | 40 | 36,63 |

| Mill-1, 10mm | 22 | 5,2° | 7,0° | 31,25 | 44 | 40,63 |

| Mill-1, 10mm | 25 | 4,2° | 5,3° | 37,26 | 50 | 46,62 |

| Mill-1, 10mm | 28 | 3,5° | 4,3° | 43,26 | 56 | 52,62 |

| Mill-1, 10mm | 32 | 2,8° | 3,3° | 51,27 | 64 | 60,62 |

| Mill-1, 10mm | 40 | 2,0° | 2,3° | 67,30 | 80 | 76,61 |

| Mill-1, 10mm | 42 | 1,9° | 2,1° | 71,32 | 82 | 80,60 |

| Mill-1, 10mm | 50 | 1,5° | 1,6° | 87,53 | 100 | 96,86 |

| Mill-1, 10mm | 63 | 1,2° | 1,2° | 113,54 | 126 | 122,86 |

| Mill-1, 10mm | 80 | 0,9° | 0,9° | 147,54 | 160 | 156,85 |

| Mill-1, 10mm | 100 | 0,7° | 0,7° | 187,54 | 200 | 196,85 |

| Mill 1-10TM • Ramping Angles • Inch | ||||||

| insert style | cutting diameter | max ramp angle to non-cutting corner tangent | max ramp angle to steel body interference | DH min [Inch] - (min hole diameter) | DH max [Inch] - (max hole diameter) | DHI [Inch] - (max flat-bottomed hole diameter) |

| Mill-1, 10mm | .500 | not recommended | not recommended | not recommended | not recommended | not recommended |

| Mill-1, 10mm | .625 | 9.9° | 12.5° | .758 | 1.250 | 1.121 |

| Mill-1, 10mm | .750 | 6.8° | 9.7° | .998 | 1.500 | 1.367 |

| Mill-1, 10mm | .875 | 5.1° | 6.8° | 1.248 | 1.750 | 1.617 |

| Mill-1, 10mm | 1.000 | 4.1° | 5.1° | 1.498 | 2.000 | 1.867 |

| Mill-1, 10mm | 1.100 | 3.5° | 4.3° | 1.698 | 2.200 | 2.067 |

| Mill-1, 10mm | 1.250 | 2.9° | 3.4° | 1.999 | 2.500 | 2.367 |

| Mill-1, 10mm | 1.500 | 2.2° | 2.4° | 2.499 | 3.000 | 2.867 |

| Mill-1, 10mm | 2.000 | 1.2° | 1.6° | 3.509 | 4.000 | 3.876 |

| Mill-1, 10mm | 2.500 | 1.2° | 1.2° | 4.509 | 5.000 | 4.876 |

| Mill-1, 10mm | 3.000 | 0.9° | 1.0° | 5.509 | 6.000 | 5.876 |

| Mill-1, 10mm | 4.000 | 0.7° | 0.7° | 7.509 | 8.000 | 7.876 |