Průkopník v oblasti materiálové vědy

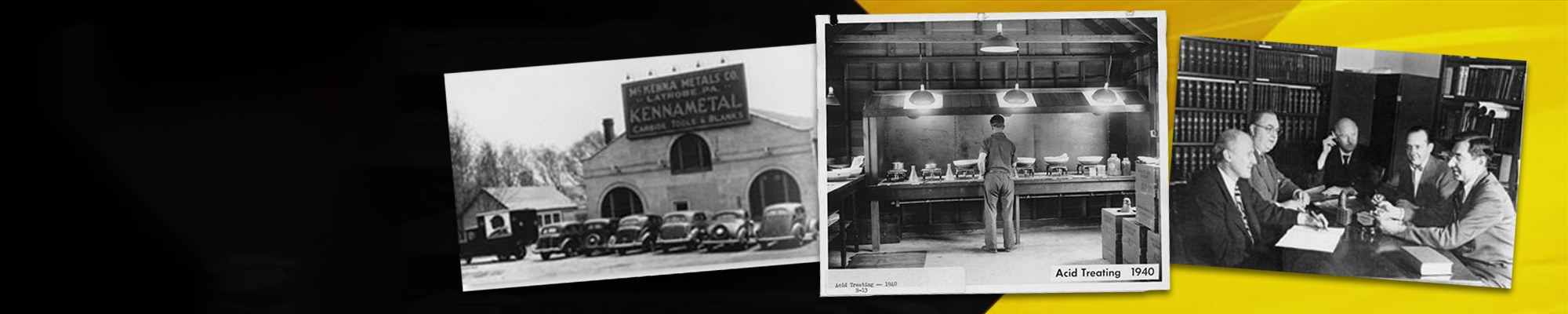

Boříme bariéry v oblasti materiálových věd. Tohle poslání začalo před 85 lety u našeho zakladatele metalurga Philipa M. McKenna a od té doby pokračuje. Po letech výzkumu vytvořil McKenna slitinu karbidu wolframu a titanu, která přinesla průlom v produktivitě při obrábění oceli. Díky McKennově inovaci dokáží nástroje Kennametal řezat rychleji a vydrží déle než konkurenční produkty, což umožňuje zákazníkům napříč průmyslovými odvětvími – od dopravy po letecký průmysl – obrábět kovy dosud nevídanou rychlostí.