Produkt podobný k:

Dodeka™ • Karbidové břitové destičky • HNGJ-LD • Lehké obrábění

Čelní frézy

Objednací číslo3331175

ISO katalogové IDHNGJ0905ANENLDANSI katalogové IDHNGJ535ANENLD

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Objednací číslo | 3331175 |

| ISO katalogové ID | HNGJ0905ANENLD |

| ANSI katalogové ID | HNGJ535ANENLD |

| Grade | KC725M |

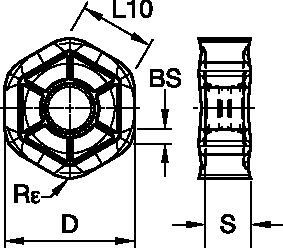

| [D] Insert IC Size | 15.875 mm |

| [D] Insert IC Size | 0.625 in |

| [BS] Corner Facet Length | 1.758 mm |

| [BS] Corner Facet Length | 0.0692 in |

| [L10] Insert Cutting Edge Length | 8.582 mm |

| [L10] Insert Cutting Edge Length | 0.3379 in |

| [Rε] Corner Radius | 1.2 mm |

| [Rε] Corner Radius | 0.047 in |

| [S] Insert Thickness | 5.556 mm |

| [S] Insert Thickness | 0.2188 in |

| Average Chip Thickness [HM] | 0.05 mm |

| Average Chip Thickness [HM] | 0.002 in |

| Cutting Edges per Insert | 12 |

Materiály obrobků

- Steel

- Stainless Steel

- High-Temp Alloys

Karbidy

KC725M

Coated carbide grade with an advanced PVD TiAlN coating. KC725M is a high-performance grade for milling steel, stainless steel, and high-temperature alloys. The good thermal shock resistance of the substrate makes this grade ideal for both wet and dry machining. Primarily for use in general and heavy machining.

Vlastnosti a výhody

- Precision ground insert with polished rake face

- Insert for Dodeka 15/45 cutters (metric)

- Insert for Dodeka 75/45 cutters (inch)

Vytvořit řešení pro výpočet posuvů a rychlosti

Po vytvoření řešení stačí vybrat ikonu Posuvy & Rychlosti a náš systém poskytne doporučení. Informace můžete upravit přidáním zařízení a specifikací nebo provést úpravy pomocí posuvníků.

Výběr břitové destičky

| Materiálová skupina | Lehké obrábění | Střední | Těžké obrábění | Těžké obrábění | ||||||||

| P1–P2 | .E..LD | KC522M | .E..LP | KC522M | .E..GP | KC522M | .S..GD | KC522M | .S..HD | KC725M | ||

| P3–P4 | .E..LD | KCPK30 | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPK30 | .S..HD | KCPK30 | ||

| P5–P6 | .E..LD | KC725M | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPM40 | .S..HD | KCPM40 | ||

| M1–M2 | .E..LD | KC522M | .E..LM | KC522M | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 | ||

| M3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCPM40 | ||

| K1–K2 | .E..LD | KCK20B | .E..LP | KCK20B | .E..LP | KCK20B | .S..GD | KCK15 | .S..HD | KCK15 | .ANSN | KY3500 |

| K3 | .E..LD | KCK20B | .E..LP | KCKP30 | .E..LP | KCPK30 | .S..GD | KCK20B | .S..HD | KCPK30 | ||

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | ||

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | ||

| S1–S2 | .E..LD | KC725M | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KC725M | .S..HD | KC725M | ||

| S3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 | ||

| S4 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 | ||

| H1 | .E..GP | KC522M | ||||||||||

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data