Produkt podobný k:

DUO-LOCK™ • KenCut™ RR • Radiused • 4 & 6 Flutes • Inch

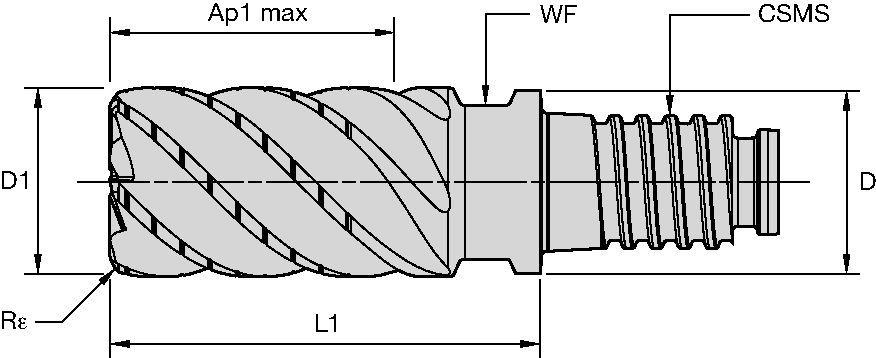

Modular End Milling • RKDF Style

Objednací číslo6126920

ISO katalogové IDRKDF0625Y4CQBANSI katalogové IDRKDF0625Y4CQB

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: X (variable)

Helix Angle: 45°

Corner Style: Corner Radius

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Objednací číslo | 6126920 |

| ISO katalogové ID | RKDF0625Y4CQB |

| ANSI katalogové ID | RKDF0625Y4CQB |

| Grade | KCSM15 |

| Adapter Style Machine Side | DUO-LOCK |

| [D] Adapter / Shank / Bore Diameter | 15.375 mm |

| [D] Adapter / Shank / Bore Diameter | 0.6053 in |

| [L1] Gage Length | 35.7 mm |

| [L1] Gage Length | 1.4055 in |

| [CSMS] System Size Machine Side | DL16 |

| [WF] Width of Flat | 13 mm |

| [WF] Width of Flat | 0.5118 in |

| [Re] Corner Radius | 0.75 mm |

| [Re] Corner Radius | 0.03 in |

| [Z] Number of Flutes | 4 |

| [D1] Effective Cutting Diameter | 15.875 mm |

| [D1] Effective Cutting Diameter | 0.625 in |

| [AP1MAX] 1st Maximum Cutting Depth | 23.812 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.9375 in |

Materiály obrobků

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Použití

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: X (variable)

Helix Angle: 45°

Corner Style: Corner Radius

Karbidy

KCSM15

Coated carbide grade with thick PVD coating and optimized chemistry

and process for increased wear resistance. Outstanding protection in milling stainless steel to mitigate crater, DOCN (depth-of-cut notching), and flank wear. Excellent performance up to 52 HRC.

Vlastnosti a výhody

- Center cutting.

- Shallow-pitch profile reduces machine power consumption.

- Standard items listed. Additional styles and coatings made-to-order.

Vytvořit řešení pro výpočet posuvů a rychlosti

Po vytvoření řešení stačí vybrat ikonu Posuvy & Rychlosti a náš systém poskytne doporučení. Informace můžete upravit přidáním zařízení a specifikací nebo provést úpravy pomocí posuvníků.

Řezné podmínky

RKDF • Inch

| Materiálová skupina |  |  | krátké | střední | dlouhé | Doporučený posuv na zub (IPT = palce/zub) při bočním frézování (A). Při drážkování (B) snižte posuv na zub IPT o 20%. | |||||||||||||

| A | B | s adaptérem | Průměr D1 | ||||||||||||||||

| KCSM15 | KCSM15 | KCSM15 | |||||||||||||||||

| Řezná rychlost | Řezná rychlost | Řezná rychlost | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||||||

| ap | ae | ap | Min | Max | Min | Max | Min | Max | dec. | .3750 | .5000 | .6250 | .7500 | 1.000 | |||||

| P | 3 | 1.0 x D | 0.5 x D | 0.75 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0019 | .0025 | .0029 | .0033 | .0033 |

| 4 | 1.0 x D | 0.3 x D | 0.75 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0017 | .0022 | .0026 | .0029 | .0028 | |

| 5 | 1.0 x D | 0.4 x D | 0.75 x D | 200 | – | 330 | 170 | – | 280.5 | 160 | – | 264 | IPT | .0016 | .0020 | .0023 | .0026 | .0026 | |

| 6 | 1.0 x D | 0.3 x D | 0.3 x D | 160 | – | 250 | 136 | – | 212.5 | 128 | – | 200 | IPT | .0013 | .0016 | .0019 | .0021 | .0020 | |

| M | 1 | 1.0 x D | 0.4 x D | 0.75 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0019 | .0025 | .0029 | .0033 | .0033 |

| 2 | 1.0 x D | 0.4 x D | 0.75 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0016 | .0020 | .0023 | .0026 | .0026 | |

| 3 | 1.0 x D | 0.4 x D | 0.75 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0013 | .0016 | .0019 | .0021 | .0020 | |

| K | 1 | 1.0 x D | 0.5 x D | 1 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0023 | .0029 | .0034 | .0037 | .0035 |

| 2 | 1.0 x D | 0.5 x D | 1 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0019 | .0025 | .0029 | .0033 | .0033 | |

| 3 | 1.0 x D | 0.5 x D | 1 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0016 | .0020 | .0023 | .0026 | .0026 | |

| S | 1 | 1.0 x D | 0.3 x D | 0.75 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0019 | .0025 | .0029 | .0033 | .0033 |

| 2 | 1.0 x D | 0.3 x D | 0.75 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0018 | |

| 3 | 1.0 x D | 0.3 x D | 0.75 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0018 | |

| 4 | 1.0 x D | 0.4 x D | 0.75 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0014 | .0018 | .0021 | .0024 | .0024 | |

| H | 1 | 1.0 x D | 0.3 x D | 0.3 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0017 | .0022 | .0026 | .0029 | .0028 |

| 2 | 1.0 x D | 0.2 x D | 0.2 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0013 | .0016 | .0019 | .0021 | .0020 | |

| 3 | 1.0 x D | 0.2 x D | 0.2 x D | 200 | – | 300 | 160 | – | 240 | 120 | – | 180 | IPT | .0010 | .0013 | .0015 | .0018 | .0018 | |

Tolerance

| Tolerance stopkových fréz | |

| D1 | tolerance d11 |

| 13/32 | -0.002/-0.0063" |

| 23/32 | -0.026/ -0.0077" |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data