Produkt podobný k:

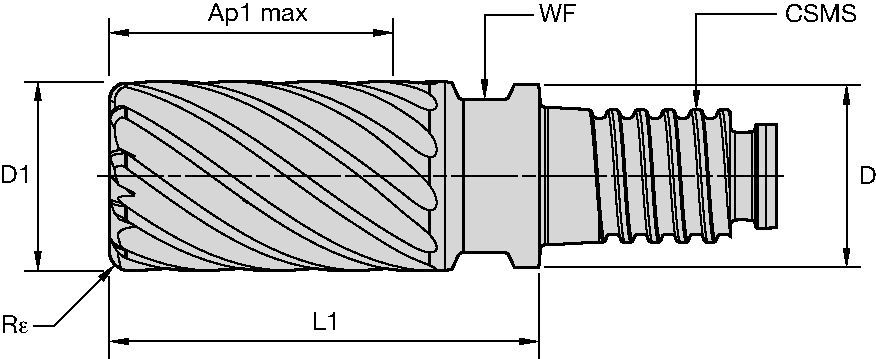

DUO-LOCK • RSM II™ • Radiused • Multi-Flute • Inch

RSM II • FSDE • High-Performance Finishing

Objednací číslo6127058

ISO katalogové IDFSDE0375Y9CQAANSI katalogové IDFSDE0375Y9CQA

- P Steel

- M Stainless Steel

- S High-Temp Alloys

- H Hardened Materials

Helix Angle: 36°

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: X (variable)

Corner Style: Corner Radius

Side Milling/Shoulder Milling: Fine Finishing

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Objednací číslo | 6127058 |

| ISO katalogové ID | FSDE0375Y9CQA |

| ANSI katalogové ID | FSDE0375Y9CQA |

| Grade | KC643M |

| Adapter Style Machine Side | DUO-LOCK |

| [D] Adapter / Shank / Bore Diameter | 9.125 mm |

| [D] Adapter / Shank / Bore Diameter | 0.3593 in |

| [L1] Gage Length | 21.4 mm |

| [L1] Gage Length | 0.8425 in |

| [CSMS] System Size Machine Side | DL10 |

| [WF] Width of Flat | 8 mm |

| [WF] Width of Flat | 0.315 in |

| [Re] Corner Radius | 0.375 mm |

| [Re] Corner Radius | 0.015 in |

| [Z] Number of Flutes | 9 |

| [D1] Effective Cutting Diameter | 9.525 mm |

| [D1] Effective Cutting Diameter | 0.375 in |

| [AP1MAX] 1st Maximum Cutting Depth | 14.288 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.5625 in |

Materiály obrobků

- Steel

- Stainless Steel

- High-Temp Alloys

- Hardened Materials

Použití

Helix Angle: 36°

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: X (variable)

Corner Style: Corner Radius

Side Milling/Shoulder Milling: Fine Finishing

Karbidy

KC643M

Coated fine-grain grade with PVD multilayer (AlTiN). KC643M™ is a very thin and hard PVD coating particularly suited for cutting steel, cast iron, stainless steel (wet), and titanium (wet). This grade can be used for materials with hardness up to 52 HRC.

Vlastnosti a výhody

- Non-center cutting.

- Optimized geometry for titanium machining.

- Unequal flute spacing minimizes chatter for smoother machining.

- Standard items listed. Additional styles and coatings made-to-order.

Vytvořit řešení pro výpočet posuvů a rychlosti

Po vytvoření řešení stačí vybrat ikonu Posuvy & Rychlosti a náš systém poskytne doporučení. Informace můžete upravit přidáním zařízení a specifikací nebo provést úpravy pomocí posuvníků.

Řezné podmínky

FSDE • Inch

| Materiálová skupina |  | krátké | střední | dlouhé | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||

| A | s adaptérem | Průměr D1 | ||||||||||||||||

| KC643M | KC643M | KC643M | ||||||||||||||||

| Řezná rychlost | Řezná rychlost | Řezná rychlost | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||||

| ap | ae | Min | Max | Min | Max | Min | Max | dec. | .375 | .500 | .625 | .750 | 1.000 | |||||

| P | 4 | Ap max | 0.008 | 445 | – | 1628 | 401 | – | 1465 | 401 | – | 1465 | IPT | .0045 | .0053 | .0058 | .0061 | .0066 |

| 5 | Ap max | 0.008 | 295 | – | 1078 | 251 | – | 916 | 236 | – | 862 | IPT | .0040 | .0048 | .0052 | .0056 | .0061 | |

| M | 1 | Ap max | 0.008 | 445 | – | 1243 | 356 | – | 994 | 312 | – | 870 | IPT | .0050 | .0060 | .0066 | .0070 | .0077 |

| 2 | Ap max | 0.008 | 295 | – | 869 | 236 | – | 695 | 207 | – | 608 | IPT | .0040 | .0048 | .0052 | .0056 | .0061 | |

| 3 | Ap max | 0.008 | 295 | – | 759 | 236 | – | 607 | 207 | – | 531 | IPT | .0033 | .0040 | .0043 | .0045 | .0048 | |

| S | 1 | Ap max | 0.008 | 245 | – | 979 | 196 | – | 783 | 147 | – | 587 | IPT | .0050 | .0060 | .0066 | .0070 | .0077 |

| 2 | Ap max | 0.008 | 125 | – | 429 | 100 | – | 343 | 75 | – | 257 | IPT | .0026 | .0032 | .0035 | .0037 | .0041 | |

| 3 | Ap max | 0.008 | 125 | – | 429 | 100 | – | 343 | 75 | – | 257 | IPT | .0026 | .0032 | .0035 | .0037 | .0041 | |

| 4 | Ap max | 0.008 | 245 | – | 649 | 196 | – | 519 | 147 | – | 389 | IPT | .0037 | .0044 | .0048 | .0051 | .0056 | |

| H | 1 | Ap max | 0.008 | 395 | – | 1518 | 316 | – | 1214 | 237 | – | 911 | IPT | .0045 | .0053 | .0058 | .0061 | .0066 |

| 2 | Ap max | 0.008 | 345 | – | 1298 | 276 | – | 1038 | 207 | – | 779 | IPT | .0033 | .0040 | .0043 | .0045 | .0048 | |

Tolerance

| Tolerance stopkových fréz | |

| D1 | tolerance e8 |

| 13/32 | -0,00126"/-0,00232" |

| 23/32 | -0,00157"/-0,00287" |

| -0,00197''/-0,00350'' | |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data