Produkt podobný k:

Mill 1-18™ • Shell Mill • Inch

Shoulder milling cutter for multiple materials

Objednací číslo2267542

ISO katalogové ID50B03RS90ED18D-UANSI katalogové IDM1D200E1803S075L157

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

- .caption

Face Milling

Helical Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Milling - Through Coolant

Milling - Side and Face

Pocketing

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Přehled

- Řezné podmínky

- Stahování

- Kompatibilní díly strana stroje

- Kompatibilní díly strana obrobku

- Náhradní díly

- Posouzení

- Otázky A Odpovědi

| Objednací číslo | 2267542 |

| ISO katalogové ID | 50B03RS90ED18D-U |

| ANSI katalogové ID | M1D200E1803S075L157 |

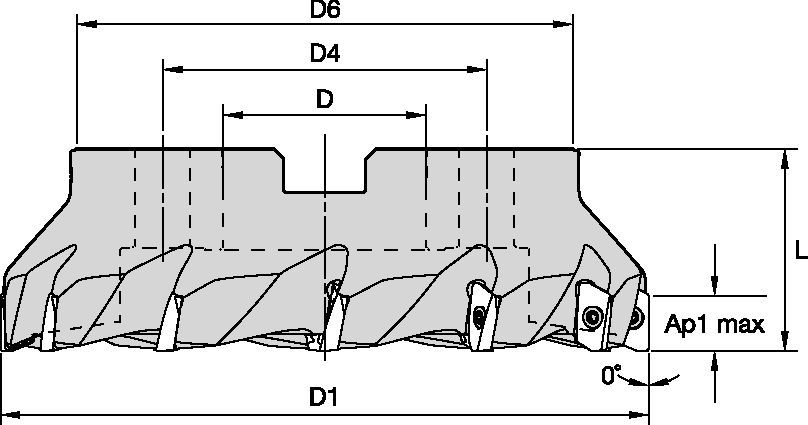

| [D1] Effective Cutting Diameter | 50.8 mm |

| [D1] Effective Cutting Diameter | 2 in |

| [D] Adapter / Shank / Bore Diameter | 19.06 mm |

| [D] Adapter / Shank / Bore Diameter | 0.75 in |

| [D6] Hub Diameter | 42.86 mm |

| [D6] Hub Diameter | 1.688 in |

| [L] Overall Length | 40 mm |

| [L] Overall Length | 1.575 in |

| [AP1MAX] 1st Maximum Cutting Depth | 17.7 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.7 in |

| Number of Inserts | 3 |

| Weight Pounds | 0.71 |

| Max RPM | 24670 |

Materiály obrobků

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

- .caption

Použití

Face Milling

Helical Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Milling - Through Coolant

Milling - Side and Face

Pocketing

Vlastnosti a výhody

- Internal coolant supply.

- For ramping, slotting, plunging, facing, and true 90° walls.

Vytvořit řešení pro výpočet posuvů a rychlosti

Po vytvoření řešení stačí vybrat ikonu Posuvy & Rychlosti a náš systém poskytne doporučení. Informace můžete upravit přidáním zařízení a specifikací nebo provést úpravy pomocí posuvníků.

Posuvy

Doporučené počáteční hodnoty posuvů [mm]

| Mill 1-18™ • Recommended Starting Feeds [mm/th] | |||||||||||||||

| Geometrie břitových destiček | Doporučené počáteční posuvy na zub (Fz) podle % poměru radiální hloubky řezu (ae) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .F..LDJ | 0,12 | 0,46 | 0,82 | 0,08 | 0,33 | 0,59 | 0,06 | 0,25 | 0,44 | 0,06 | 0,22 | 0,38 | 0,05 | 0,20 | 0,35 |

| .E..LDJ | 0,12 | 0,45 | 0,80 | 0,08 | 0,33 | 0,58 | 0,06 | 0,24 | 0,43 | 0,06 | 0,21 | 0,38 | 0,05 | 0,20 | 0,35 |

| .E..LD | 0,17 | 0,47 | 0,82 | 0,12 | 0,34 | 0,59 | 0,09 | 0,26 | 0,44 | 0,08 | 0,22 | 0,38 | 0,07 | 0,20 | 0,35 |

| .E..GD | 0,23 | 0,52 | 0,89 | 0,17 | 0,37 | 0,64 | 0,13 | 0,28 | 0,48 | 0,11 | 0,24 | 0,42 | 0,10 | 0,22 | 0,38 |

| .S..GE | 0,23 | 0,51 | 0,89 | 0,17 | 0,37 | 0,64 | 0,13 | 0,27 | 0,48 | 0,11 | 0,24 | 0,42 | 0,10 | 0,22 | 0,38 |

| .S..GD | 0,23 | 0,51 | 0,89 | 0,17 | 0,37 | 0,64 | 0,13 | 0,28 | 0,48 | 0,11 | 0,24 | 0,41 | 0,10 | 0,22 | 0,38 |

| .E..HD | 0,23 | 0,59 | 0,95 | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,25 | 0,41 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||||||||||

Recommended Starting Feeds [IPT]

| Mill 1-18™ • Recommended Starting Feeds [IPT] | |||||||||||||||

| Geometrie břitových destiček | Doporučené počáteční posuvy na zub (Fz) podle % poměru radiální hloubky řezu (ae) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .F..LDJ | 0.005 | 0.019 | 0.033 | 0.003 | 0.013 | 0.023 | 0.003 | 0.010 | 0.018 | 0.002 | 0.009 | 0.015 | 0.002 | 0.008 | 0.014 |

| .E..LDJ | 0.005 | 0.018 | 0.032 | 0.003 | 0.013 | 0.023 | 0.003 | 0.010 | 0.017 | 0.002 | 0.009 | 0.015 | 0.002 | 0.008 | 0.014 |

| .E..LD | 0.007 | 0.019 | 0.032 | 0.005 | 0.013 | 0.023 | 0.004 | 0.010 | 0.017 | 0.003 | 0.009 | 0.015 | 0.003 | 0.008 | 0.014 |

| .E..GD | 0.009 | 0.020 | 0.035 | 0.007 | 0.015 | 0.025 | 0.005 | 0.011 | 0.019 | 0.004 | 0.010 | 0.016 | 0.004 | 0.009 | 0.015 |

| .S..GE | 0.009 | 0.020 | 0.035 | 0.007 | 0.014 | 0.025 | 0.005 | 0.011 | 0.019 | 0.004 | 0.009 | 0.017 | 0.004 | 0.009 | 0.015 |

| .S..GD | 0.009 | 0.020 | 0.035 | 0.007 | 0.015 | 0.025 | 0.005 | 0.011 | 0.019 | 0.004 | 0.009 | 0.016 | 0.004 | 0.009 | 0.015 |

| .E..HD | 0.009 | 0.023 | 0.037 | 0.007 | 0.017 | 0.027 | 0.005 | 0.013 | 0.020 | 0.004 | 0.011 | 0.017 | 0.004 | 0.010 | 0.016 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||||||||||

Rychlosti

Doporučené počáteční řezné rychlosti [m/min]

| Mill 1-18™ • Recommended Starting Speed [m/min] | |||||||||||||||||||||||||||||||

| Sorta | KC410M | KC422M | KC522M | KC725M | KCK15 | KCPK30 | KCK20B | KCPM40 | KCSM30 | KCSM40 | |||||||||||||||||||||

| Tloušťka třísky hex mm | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |||||||||||

| Materiálová skupina | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | – | – | – | – | – | – | 330 | 285 | 270 | 260 | 230 | 215 | – | – | – | 455 | 395 | 370 | – | – | – | 295 | 260 | 245 | 370 | 320 | 300 | 350 | 320 | 300 |

| 2 | – | – | – | – | – | – | 275 | 240 | 200 | 220 | 190 | 160 | – | – | – | 280 | 255 | 230 | – | – | – | 250 | 215 | 180 | 305 | 270 | 220 | 300 | 270 | 220 | |

| 3 | – | – | – | – | – | – | 255 | 215 | 175 | 200 | 170 | 140 | – | – | – | 255 | 230 | 205 | – | – | – | 230 | 195 | 160 | 285 | 240 | 195 | 280 | 240 | 195 | |

| 4 | – | – | – | – | – | – | 225 | 185 | 150 | 180 | 150 | 120 | – | – | – | 225 | 185 | 160 | – | – | – | 205 | 170 | 135 | 250 | 205 | 165 | 240 | 205 | 165 | |

| 5 | – | – | – | – | – | – | 185 | 170 | 150 | 150 | 135 | 120 | – | – | – | 190 | 170 | 150 | – | – | – | 170 | 155 | 135 | 205 | 190 | 165 | 200 | 180 | 160 | |

| 6 | – | – | – | – | – | – | 165 | 125 | 100 | 130 | 100 | 80 | – | – | – | 160 | 135 | 110 | – | – | – | 150 | 115 | 90 | 185 | 140 | 110 | 180 | 140 | 100 | |

| M | 1 | – | – | – | – | – | – | 205 | 180 | 165 | 170 | 150 | 135 | – | – | – | 205 | 185 | 155 | – | – | – | 195 | 170 | 155 | 225 | 180 | 170 | 260 | 210 | 185 |

| 2 | – | – | – | – | – | – | 185 | 160 | 130 | 155 | 130 | 110 | – | – | – | 185 | 160 | 140 | – | – | – | 175 | 150 | 125 | 205 | 160 | 135 | 235 | 180 | 145 | |

| 3 | – | – | – | – | – | – | 140 | 120 | 95 | 115 | 100 | 80 | – | – | – | 145 | 130 | 115 | – | – | – | 130 | 115 | 90 | 155 | 125 | 95 | 175 | 145 | 110 | |

| K | 1 | – | – | – | – | – | – | 230 | 205 | 185 | – | – | – | 420 | 385 | 340 | 295 | 265 | 240 | 360 | 290 | 245 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 180 | 160 | 150 | – | – | – | 335 | 295 | 275 | 235 | 210 | 190 | 280 | 230 | 195 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 150 | 135 | 120 | – | – | – | 280 | 250 | 230 | 195 | 175 | 160 | 210 | 175 | 140 | – | – | – | – | – | – | – | – | – | |

| N | 1 | 1215 | 1080 | 995 | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 1080 | 995 | 915 | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 1080 | 995 | 915 | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | 50 | 40 | 25 |

| 2 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | 55 | 40 | 25 | |

| 3 | – | – | – | – | – | – | 50 | 40 | 25 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | 55 | 45 | 30 | 65 | 45 | 30 | |

| 4 | – | – | – | – | – | – | 50 | 45 | 35 | 50 | 45 | 30 | – | – | – | 50 | 45 | 35 | – | – | – | 55 | 50 | 35 | 60 | 55 | 40 | 75 | 60 | 40 | |

| H | 1 | – | – | – | – | – | – | 120 | 90 | 70 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 135 | 100 | 75 | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||||||||||||||||||||||||||

| Mill 1-18™ • Recommended Starting Speed [SFM] | |||||||||||||||||||||||||||||||

| Sorta | KC410M | KC422M | KC522M | KC725M | KCK15 | KCPK30 | KCK20B | KCPM40 | KCSM30 | KCSM40 | |||||||||||||||||||||

| Chip Thickness hex Inch | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |||||||||||

| Materiálová skupina | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | – | – | – | – | – | – | 330 | 285 | 270 | 260 | 230 | 215 | – | – | – | 455 | 395 | 370 | – | – | – | 295 | 260 | 245 | 370 | 320 | 300 | 350 | 320 | 300 |

| 2 | – | – | – | – | – | – | 275 | 240 | 200 | 220 | 190 | 160 | – | – | – | 280 | 255 | 230 | – | – | – | 250 | 215 | 180 | 305 | 270 | 220 | 300 | 270 | 220 | |

| 3 | – | – | – | – | – | – | 255 | 215 | 175 | 200 | 170 | 140 | – | – | – | 255 | 230 | 205 | – | – | – | 230 | 195 | 160 | 285 | 240 | 195 | 280 | 240 | 195 | |

| 4 | – | – | – | – | – | – | 225 | 185 | 150 | 180 | 150 | 120 | – | – | – | 225 | 185 | 160 | – | – | – | 205 | 170 | 135 | 250 | 205 | 165 | 240 | 205 | 165 | |

| 5 | – | – | – | – | – | – | 185 | 170 | 150 | 150 | 135 | 120 | – | – | – | 190 | 170 | 150 | – | – | – | 170 | 155 | 135 | 205 | 190 | 165 | 200 | 180 | 160 | |

| 6 | – | – | – | – | – | – | 165 | 125 | 100 | 130 | 100 | 80 | – | – | – | 160 | 135 | 110 | – | – | – | 150 | 115 | 90 | 185 | 140 | 110 | 180 | 140 | 100 | |

| M | 1 | – | – | – | – | – | – | 205 | 180 | 165 | 170 | 150 | 135 | – | – | – | 205 | 185 | 155 | – | – | – | 195 | 170 | 155 | 225 | 180 | 170 | 260 | 210 | 185 |

| 2 | – | – | – | – | – | – | 185 | 160 | 130 | 155 | 130 | 110 | – | – | – | 185 | 160 | 140 | – | – | – | 175 | 150 | 125 | 205 | 160 | 135 | 235 | 180 | 145 | |

| 3 | – | – | – | – | – | – | 140 | 120 | 95 | 115 | 100 | 80 | – | – | – | 145 | 130 | 115 | – | – | – | 130 | 115 | 90 | 155 | 125 | 95 | 175 | 145 | 110 | |

| K | 1 | – | – | – | – | – | – | 230 | 205 | 185 | – | – | – | 420 | 385 | 340 | 295 | 265 | 240 | 360 | 290 | 245 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 180 | 160 | 150 | – | – | – | 335 | 295 | 275 | 235 | 210 | 190 | 280 | 230 | 195 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 150 | 135 | 120 | – | – | – | 280 | 250 | 230 | 195 | 175 | 160 | 210 | 175 | 140 | – | – | – | – | – | – | – | – | – | |

| N | 1 | 1215 | 1080 | 995 | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 1080 | 995 | 915 | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 1080 | 995 | 915 | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | 50 | 40 | 25 |

| 2 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | 55 | 40 | 25 | |

| 3 | – | – | – | – | – | – | 50 | 40 | 25 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | 55 | 45 | 30 | 65 | 45 | 30 | |

| 4 | – | – | – | – | – | – | 50 | 45 | 35 | 50 | 45 | 30 | – | – | – | 50 | 45 | 35 | – | – | – | 55 | 50 | 35 | 60 | 55 | 40 | 75 | 60 | 40 | |

| H | 1 | – | – | – | – | – | – | 120 | 90 | 70 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 135 | 100 | 75 | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||||||||||||||||||||||||||

Řezné podmínky

Příklady aplikací

| Mill 1-18™ • Ramping Angles [mm] | |||||

| Typ břitové destičky | řezný průměr | max. sestupný úhel | DH min [mm] - (min hole diameter) | DH min (Minimální průměr otvoru) | DHI min (Minimální průměr otvoru plochého dna) |

| Mill-1, 18mm | 25 | 17˚ | 29,24 | 50 | 45,84 |

| Mill-1, 18mm | 32 | 11˚ | 42,98 | 64 | 59,84 |

| Mill-1, 18mm | 40 | 8˚ | 58,92 | 80 | 75,84 |

| Mill-1, 18mm | 50 | 5˚ | 78,88 | 100 | 95,84 |

| Mill-1, 18mm | 63 | 4˚ | 104,86 | 126 | 121,84 |

| Mill-1, 18mm | 80 | 3˚ | 139,02 | 160 | 156,5 |

| Mill-1, 18mm | 100 | 2˚ | 179,00 | 200 | 196,5 |

| Mill-1, 18mm | 125 | 2˚ | 228,98 | 250 | 246,5 |

| Mill-1, 18mm | 160 | 1˚ | 298,98 | 320 | 316,5 |

Application Examples

| Mill 1-18™ • Ramping Angles [Inch] | |||||

| Typ břitové destičky | řezný průměr | max. sestupný úhel | DH min [Inch] - (min hole diameter) | DH min (Minimální průměr otvoru) | DHI min (Minimální průměr otvoru plochého dna) |

Výběr břitové destičky

Výběr břitové destičky

| Materiálová skupina | Lehké obrábění | Všeobecné použití | Těžké obrábění | |||

| – | (Lehká geometrie) | – | (Silná geometrie) | |||

| – | Odolnost proti opotřebení |  | Houževnatost | |||

| – | Geometrie | Sorta | Geometrie | Sorta | Geometrie | Sorta |

| P1–P2 | .E..GD | KCPM40 | .S..GD | KCPM40 | .E..HD | KCPM40 |

| P3–P4 | .E..GD | KCPK30 | .S..GD | KCPK30 | .E..HD | KCPK30 |

| P5–P6 | .E..GD | KC725M | .S..GD | KC725M | .E..HD | KC725M |

| M1–M2 | .E..GD | KCSM40 | .S..GD | KCSM40 | .E..HD | KCSM40 |

| M3 | .E..GD | KCPM40 | .S..GD | KCPM40 | .E..HD | KCPM40 |

| K1–K2 | .E..GD | KCK20B | .E..GD | KCK20B | .S..GD | KCK15 |

| K3 | .E..GD | KCK20B | .S..GD | KCK15 | .E..HD | KCPK30 |

| N1–N2 | .F..LDJ | KC410M | .E..LDJ | KC422M | .E..LDJ | KC422M |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

| S1–S2 | .E..GD | KC725M | .S..GD | KC725M | .E..HD | KC725M |

| S3 | .E..GD | KCSM40 | .S..GD | KCSM40 | .E..HD | KCSM40 |

| S4 | .E..GD | KCSM40 | .S..GD | KCSM40 | .E..HD | KCSM40 |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data