*に類似する製品:

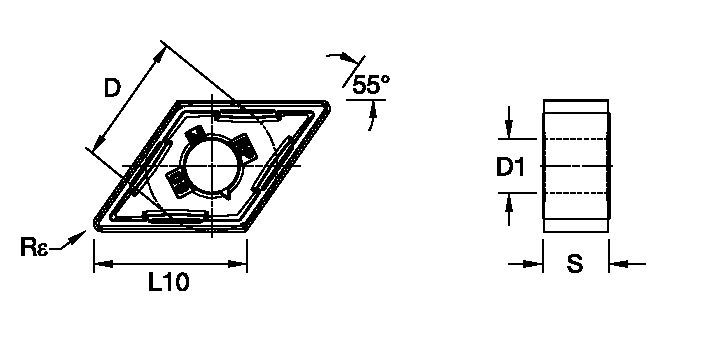

Kenloc™ • DNMGインサート • ネガティブ • RP

ISO超硬旋削インサート • 粗加工(ポジティブブレーカー形状)

製品番号3760442

ISO カタログ IDDNMG150412RPASIカタログIDDNMG433RP

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 製品番号 | 3760442 |

| ISO カタログ ID | DNMG150412RP |

| ASIカタログID | DNMG433RP |

| Grade | KCM35 |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | 0.5 in |

| [L10] Insert Cutting Edge Length | 15.504 mm |

| [L10] Insert Cutting Edge Length | 0.6104 in |

| [S] Insert Thickness | 4.76 mm |

| [S] Insert Thickness | 0.1875 in |

| [Rε] Corner Radius | 1.2 mm |

| [Rε] Corner Radius | 0.047 in |

| [D1] Insert Hole Size | 5.16 mm |

| [D1] Insert Hole Size | 0.2031 in |

ワーク材料

- Stainless Steel

- High-Temp Alloys

等級

KCM35

Composition: A multilayer TiN-MT-TiCN-Al2O3 CVD coating over a super-tough substrate.

Application: The KCM35 grade is engineered to take on the most brutal cast stainless steel machining applications. The substrate withstands heavy interruptions, while the coating provides the wear resistance needed for long tool life. The polished surface resists edge build-up, even at slow cutting speeds. KCM35 grade is available in insert sizes and geometries appropriate for heavy feeds and large depths of cut.

特徴と利点

- Roughing geometry with positive rake face for chip control in difficult materials

- Beyond™ Drive™ grades included

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

I have read and accepted the Terms & Conditions of use