*に類似する製品:

Kenloc™ • SNMGインサート • ネガティブ • RN

ISO超硬旋削インサート • 粗加工(ネガティブブレーカー形状)

製品番号3753321

ISO カタログ IDSNMG150608RNANSIカタログIDSNMG542RN

- P Steel

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 製品番号 | 3753321 |

| ISO カタログ ID | SNMG150608RN |

| ANSIカタログID | SNMG542RN |

| Grade | KCP10 |

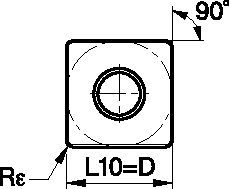

| [D] Insert IC Size | 15.875 mm |

| [D] Insert IC Size | 0.625 in |

| [L10] Insert Cutting Edge Length | 15.875 mm |

| [L10] Insert Cutting Edge Length | 0.625 in |

| [S] Insert Thickness | 6.35 mm |

| [S] Insert Thickness | 0.25 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| [D1] Insert Hole Size | 6.35 mm |

| [D1] Insert Hole Size | 0.25 in |

ワーク材料

- Steel

等級

KCP10

Composition: A specially engineered cobalt-enriched carbide grade with thick MTCVD-TiCN-Al2O3 coating for maximum wear resistance.

Application: An excellent finishing to medium machining grade for a variety of workpiece materials, including most steels, ferritic, martensitic, and PH stainless steels, and cast irons. The cobalt-enriched substrate offers a balanced combination of deformation resistance and edge toughness, while the thick coating layers offer outstanding abrasion resistance and crater wear resistance for high-speed machining. Smooth coating provides resistance to edge build-up and microchipping and produces excellent surface finishes.

特徴と利点

- Roughing geometry with stronger edge line for demanding applications

- Beyond™ Drive™ grades included

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

I have read and accepted the Terms & Conditions of use