*に類似する製品:

KTMD U Style Cutter 3/8" IC Shell Mill

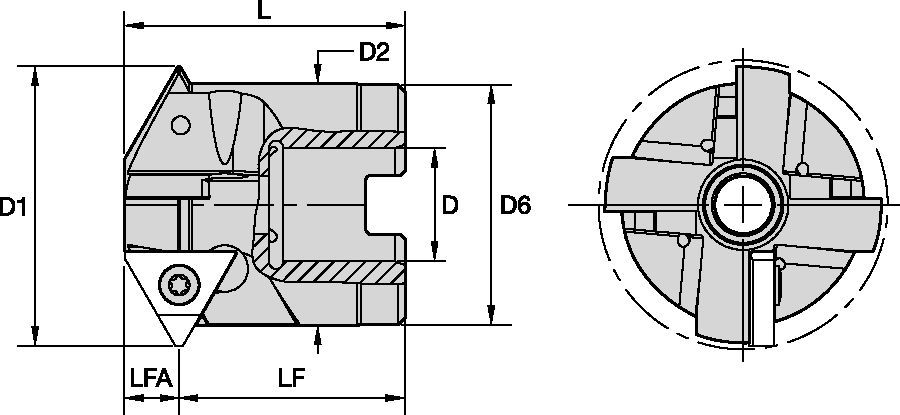

KTMD • U Style • 3/8" IC • Cutter Bodies

製品番号5593139

ISO カタログ IDKTMDUSD169L158Z4ASIカタログIDKTMDUSD169L158Z4

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

- .caption

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 製品番号 | 5593139 |

| ISO カタログ ID | KTMDUSD169L158Z4 |

| ASIカタログID | KTMDUSD169L158Z4 |

| [D1] Effective Cutting Diameter | 42.926 mm |

| [D1] Effective Cutting Diameter | 1.69 in |

| [D] Adapter / Shank / Bore Diameter | 12.7 mm |

| [D] Adapter / Shank / Bore Diameter | 0.5 in |

| [D2] Maximum Body Diameter | 34.29 mm |

| [D2] Maximum Body Diameter | 1.35 in |

| [D6] Hub Diameter | 34 mm |

| [D6] Hub Diameter | 1.339 in |

| [L] Overall Length | 40.1 mm |

| [L] Overall Length | 1.58 in |

| [LF] Functional Length | 32.2 mm |

| [LF] Functional Length | 1.268 in |

| [LFA] LF A Dimension | 7.9 mm |

| [LFA] LF A Dimension | 0.31 in |

| Number of Inserts | 4 |

| Max RPM | 3430 |

ワーク材料

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

- .caption

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

アプリケーションデータ

| ツールホルダー別ねじ切りアプリケーション | |||||||

| 最小ねじ Ø | |||||||

| ツールホルダー | D1 | ISO コース ピッチ | ISO ファインピッチ | 部分的55° | |||

| KTMDUSD169L158Z4 | 1.6900 | – | – | – | – | – | – |

| KTMDUSD209L158Z5 | 2.0900 | – | – | – | – | – | – |

切削速度および送り速度

KTMD • 3/8" IC

| 被削材 | ブリネル | 表面速度 | スローアウェイ | |

| 鋼 | HB | KC610M | KC635M | 送り量fz(IPT) |

| P1 | 125 | 325–675 | 290–590 | .002–.008 |

| P2 | 180 | 290–550 | 290–520 | .002–.008 |

| P3 | 225 | 200–425 | 225–375 | .002–.008 |

| P4 | 250 | 250–490 | 250–500 | .002–.008 |

| P5 | 275 | 250–425 | 250–500 | .002–.006 |

| P6 | 325 | 225–350 | 200–325 | .002–.004 |

| ステンレス鋼 | ||||

| M1 | 180 | 325–550 | 375–590 | .002–.004 |

| M2 | 250 | 225–450 | 325–450 | .002–.004 |

| M3 | 330 | 225–375 | 325–375 | .002–.004 |

| 鋳鉄 | ||||

| K1 | 180 | 200–425 | 325–450 | .001–.003 |

| K2 | 220 | 200–390 | 250–325 | .002–.006 |

| K3 | 260 | 160–290 | 200–275 | .002–.004 |

| 非鉄材 | ||||

| N1 | 60–100 | 325–820 | – | .002–.010 |

| 耐熱合金 | ||||

| S1 | 200 | 65–140 | 65–130 | .002–.004 |

| S2 | 250 | 65–90 | 65–90 | .001–.002 |

| S3 | 280 | 50–65 | 50–65 | .001–.002 |

| S4 | 350 | 30–50 | 30–50 | .001–.002 |

| 硬度鋼 | ||||

| H1 | 55HRc | 65–140 | 65–140 | .0004–.001 |

I have read and accepted the Terms & Conditions of use