*に類似する製品:

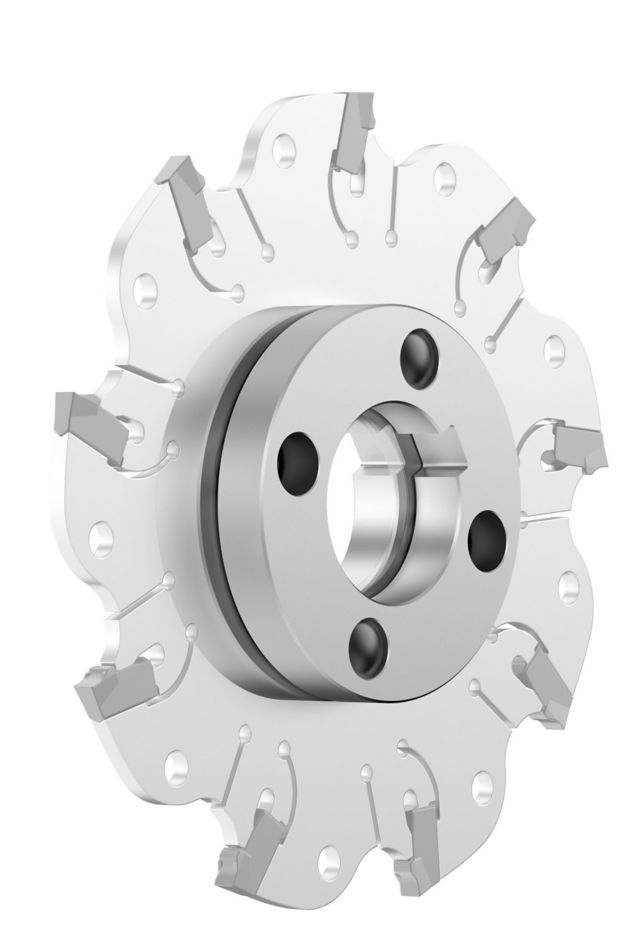

KVNS™ A2™ • Arbor Mount • Metric

Slot milling cutter for multiple materials

製品番号1246131

ISO カタログ ID4.97101116ANSIカタログID4.97101116

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- .caption

溝加工:AE/AP寸法付き側面

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

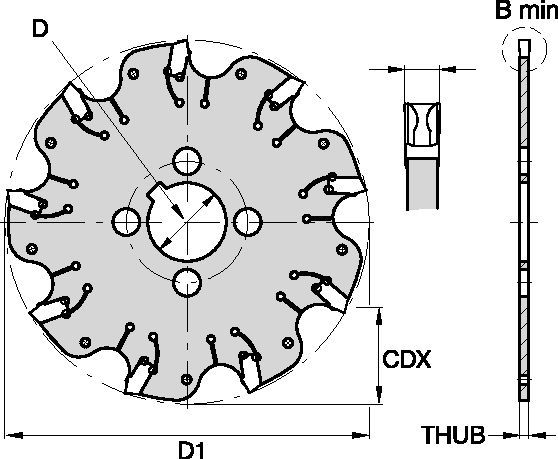

| 製品番号 | 1246131 |

| ISO カタログ ID | 4.97101116 |

| ANSIカタログID | 4.97101116 |

| [BM] Cutting Width Minimum | 1.6 mm |

| [BM] Cutting Width Minimum | 0.063 in |

| [D1] Effective Cutting Diameter | 100 mm |

| [D1] Effective Cutting Diameter | 3.937 in |

| [CDX] Radial Maximum Depth of Cut | 27 mm |

| [CDX] Radial Maximum Depth of Cut | 1.063 in |

| [D] Adapter / Shank / Bore Diameter | 22 mm |

| [D] Adapter / Shank / Bore Diameter | 0.8661 in |

| [THUB] Hub Thickness | 1.3 mm |

| [THUB] Hub Thickness | 0.0512 in |

| Number of Inserts | 9 |

| Weight Kilograms | 0.06 |

| Gage Insert | 3.90016____ |

| Max RPM | 3200 |

ワーク材料

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- .caption

使用法と用途

溝加工:AE/AP寸法付き側面

特徴と利点

- Self-clamping insert seat with fixed stop.

- Excellent for all flat-bottom slotting and cut-off operations.

- Two drive rings required for each cutter body. They must be ordered separately, and in pairs of two.

- For cutter diameters 200mm and 250mm support rings are optional (instead of drive rings). Support rings also must be ordered separately, and in pairs of two.

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

送り量

推奨送り量の開始値 [mm]

| KVNS™ A2™ Series • Recommended Starting Feeds [mm/th] | |||||||||||||||

| インサート ブレーカ形状 | 径方向の切込み量(ae)の割合に対する1刃あたりの推奨送り量の開始値(Fz) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .S..GD | 0,23 | 0,46 | 0,71 | 0,17 | 0,33 | 0,51 | 0,13 | 0,25 | 0,38 | 0,11 | 0,22 | 0,33 | 0,10 | 0,20 | 0,30 |

| .S..GB | 0,23 | 0,46 | 0,74 | 0,17 | 0,33 | 0,54 | 0,13 | 0,25 | 0,40 | 0,11 | 0,22 | 0,35 | 0,10 | 0,20 | 0,32 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | |||||||||||||||

Recommended Starting Feeds [IPT]

| KVNS™ A2™ Series • Recommended Starting Feeds [IPT] | |||||||||||||||

| インサート ブレーカ形状 | 径方向の切込み量(ae)の割合に対する1刃あたりの推奨送り量の開始値(Fz) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .S..GD | 0.009 | 0.017 | 0.026 | 0.007 | 0.013 | 0.019 | 0.005 | 0.009 | 0.014 | 0.004 | 0.008 | 0.012 | 0.004 | 0.008 | 0.011 |

| .S..GB | 0.009 | 0.017 | 0.028 | 0.007 | 0.013 | 0.020 | 0.005 | 0.009 | 0.015 | 0.004 | 0.008 | 0.013 | 0.004 | 0.008 | 0.012 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | |||||||||||||||

速度

推奨切削速度の開始値 [m/min]

| KVNS™ A2™ Series • Recommended Starting Speed [m/min] | |||||||

| 材種 | KCPK30 | KMF | |||||

| 切り屑厚さ(hex)(mm) | 最小 | 最大 | 最小 | 最大 | |||

| 被削材 グループ | 最大 | スタート | 最小 | 最大 | スタート | 最小 | |

| P | 1 | 455 | 395 | 370 | – | – | – |

| 2 | 280 | 255 | 230 | – | – | – | |

| 3 | 255 | 230 | 205 | – | – | – | |

| 4 | 225 | 185 | 160 | – | – | – | |

| 5 | 190 | 170 | 150 | – | – | – | |

| 6 | 160 | 135 | 110 | – | – | – | |

| M | 1 | 205 | 185 | 155 | – | – | – |

| 2 | 185 | 160 | 140 | – | – | – | |

| 3 | 145 | 130 | 115 | – | – | – | |

| K | 1 | 295 | 265 | 240 | – | – | – |

| 2 | 235 | 210 | 190 | – | – | – | |

| 3 | 195 | 175 | 160 | – | – | – | |

| N | 1 | – | – | – | 335 | 298 | 271 |

| 2 | – | – | – | 335 | 298 | 271 | |

| 3 | – | – | – | 219 | 198 | 170 | |

| S | 1 | – | – | – | 30 | 24 | 20 |

| 2 | – | – | – | 30 | 24 | 20 | |

| 3 | – | – | – | 30 | 24 | 20 | |

| 4 | 50 | 45 | 35 | 24 | 24 | 24 | |

| H | 1 | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||

Recommended Starting Speeds [SFM]

| KVNS™ A2™ Series • Recommended Starting Speed [SFM] | |||||||

| 材種 | KCPK30 | KMF | |||||

| Chip Thickness hex Inch | 最小 | 最大 | 最小 | 最大 | |||

| 被削材 グループ | 最大 | スタート | 最小 | 最大 | スタート | 最小 | |

| P | 1 | 1495 | 1295 | 1215 | – | – | – |

| 2 | 920 | 835 | 755 | – | – | – | |

| 3 | 835 | 755 | 675 | – | – | – | |

| 4 | 740 | 605 | 525 | – | – | – | |

| 5 | 625 | 560 | 490 | – | – | – | |

| 6 | 525 | 445 | 360 | – | – | – | |

| M | 1 | 675 | 605 | 510 | – | – | – |

| 2 | 605 | 525 | 460 | – | – | – | |

| 3 | 475 | 425 | 375 | – | – | – | |

| K | 1 | 970 | 870 | 785 | – | – | – |

| 2 | 770 | 690 | 625 | – | – | – | |

| 3 | 640 | 575 | 525 | – | – | – | |

| N | 1 | – | – | – | 1100 | 980 | 890 |

| 2 | – | – | – | 1100 | 980 | 890 | |

| 3 | – | – | – | 720 | 650 | 560 | |

| S | 1 | – | – | – | 100 | 80 | 65 |

| 2 | – | – | – | 100 | 80 | 65 | |

| 3 | – | – | – | 100 | 80 | 65 | |

| 4 | 165 | 150 | 115 | 80 | 80 | 80 | |

| H | 1 | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||

インサート選択

インサート選択の手引き

| KVNS™ A2™ Slotting Cutters • Insert Selection Guide | ||||||

| 被削材 グループ | 軽切削加工 | 汎用 | 重切削加工 | |||

| – | (軽いブレーカー) | (強いブレーカー) | ||||

| – | 耐磨耗性 |  | 靭性 | |||

| – | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 |

| P1-P2 | .S..GD | KCPK30 | .S..GD | KCPK30 | .S..GB | KCPK30 |

| P3-P4 | .S..GD | KCPK30 | .S..GD | KCPK30 | .S..GB | KCPK30 |

| P5-P6 | .S..GD | KCPK30 | .S..GB | KCPK30 | .S..GB | KCPK30 |

| M1-M2 | .S..GD | KCPK30 | .S..GD | KCPK30 | .S..GB | KCPK30 |

| M3 | .S..GD | KCPK30 | .S..GB | KCPK30 | .S..GB | KCPK30 |

| K1-K2 | .S..GD | KCPK30 | .S..GD | KCPK30 | .S..GB | KCPK30 |

| K3 | .S..GD | KCPK30 | .S..GD | KCPK30 | .S..GB | KCPK30 |

| N1-N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1-S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use