*に類似する製品:

PCDインサート • KSDRミニチップ • E0

スローアウェイインサート

製品番号6042983

ISO カタログ IDKSDR100031E0W4SASIカタログIDKSDR100031E0W4S

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

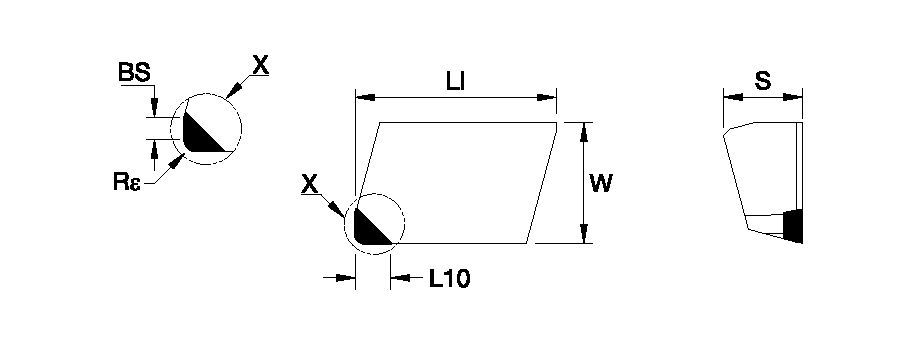

| 製品番号 | 6042983 |

| ISO カタログ ID | KSDR100031E0W4S |

| ASIカタログID | KSDR100031E0W4S |

| Grade | KD1425 |

| [W] Insert Width | 9.52 mm |

| [W] Insert Width | 0.375 in |

| [BS] Corner Facet Length | 1.52 mm |

| [BS] Corner Facet Length | 0.06 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| Average Chip Thickness [HM] | 0.02 mm |

| Average Chip Thickness [HM] | 0.0008 in |

ワーク材料

- Non-Ferrous

等級

KD1425

Composition: A multimodal PCD grade with a range of grain sizes brazed onto a carbide substrate.

Application: Engineered for extreme abrasion resistance, combined with good edge strength for demanding applications. An ideal choice for high-silicon aluminium alloys, bi-metallic (AL/GCI) materials, MMC, carbon-fibre reinforced plastics, and other abrasive non-metallic materials.

特徴と利点

- Ap1 max = 2,5mm (.100")

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

速度

推奨切削速度の開始値 [m/min]

| 被削材 グループ | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 910 | 1980 | 4880 | 910 | 1980 | 4880 |

| 3 | 460 | 610 | 760 | 460 | 610 | 760 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

| 被削材 グループ | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 910 | 1980 | 4880 | 910 | 1980 | 4880 |

| 3 | 460 | 610 | 760 | 460 | 610 | 760 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| 被削材 グループ | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 3000 | 6500 | 16000 | 3000 | 6500 | 16000 |

| 3 | 1500 | 2000 | 2500 | 1500 | 2000 | 2500 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

| 被削材 グループ | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 3000 | 6500 | 16000 | 3000 | 6500 | 16000 |

| 3 | 1500 | 2000 | 2500 | 1500 | 2000 | 2500 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

インサート選択

インサート選択の手引き • KBDM

| 被削材 グループ | 軽切削加工 | 汎用 | 重切削加工 | |||

| (軽いブレーカー) | (強いブレーカー) | |||||

| 耐磨耗性 |  | 靭性 | ||||

| ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | .KSDR….. | KD1400 | .KSDR….. | KD1400 | .KSDR….. | KD1400 |

| N3 | .KSDR….. | KD1400 | .KSDR….. | KD1425 | .KSDR….. | KD1425 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

| 被削材 グループ | 軽切削加工 | 汎用 | 重切削加工 | |||

| (軽いブレーカー) | (強いブレーカー) | |||||

| 耐磨耗性 |  | 靭性 | ||||

| ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 | ブレーカ 形状 | 材種 | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | .KSDR….. | KD1400 | .KSDR….. | KD1400 | .KSDR….. | KD1400 |

| N3 | .KSDR….. | KD1400 | .KSDR….. | KD1425 | .KSDR….. | KD1425 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use