Witamy

Potwierdź swoje preferencje

Aktualizuj preferencje

Sugestie dotyczące produktów

Product Family suggestions

Witaj, User Name

Wybrane konto:

Wystąpił problem z Twoim kontem. Skontaktuj się z działem obsługi klienta.

Konto kupującego

Zmień konto

Konto odbiorcy

Zmień konto

- Panel przyborów

- Zarządzaj zamówieniami

- Zarządzaj kanałami

- Książka adresowa

-

Powiadomienia

Oznacz wszystkie jako przeczytane - Zmień hasło

- Mój profil

- Wyloguj się

Pozycje

pomyślnie dodano do koszyka

Wyświetl koszyk

Wyświetl koszyk

Frezuj więcej za mniej dzięki naszym ofertom ograniczonym czasowo!

Kup teraz.

Pozycje

pomyślnie dodano do koszyka

Wyświetl koszyk

Wyświetl koszyk

Edytuj

Dodaj

Nazwa : {{SolutionName}}- Produkty

- /

- Drill Fix™ DFR™ • LD Inserts

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

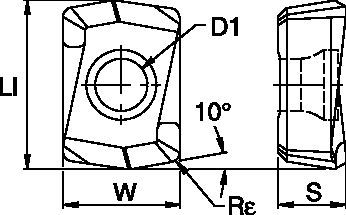

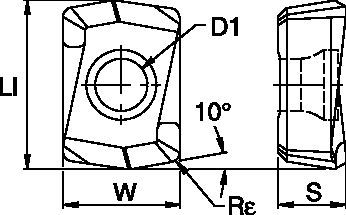

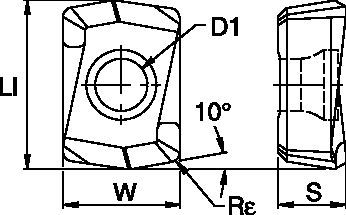

Drill Fix™ DFR™ • LD Inserts

Drill Fix™ DFR™ • LD Inserts

Właściwości i zalety

- High positive chipbreaker geometry preferred on ductile and normal chipping materials at medium feed rates.

- Preferred on inboard position.