Witamy

Potwierdź swoje preferencje

Aktualizuj preferencje

Sugestie dotyczące produktów

Product Family suggestions

Witaj, User Name

Wybrane konto:

Wystąpił problem z Twoim kontem. Skontaktuj się z działem obsługi klienta.

Konto kupującego

Zmień konto

Konto odbiorcy

Zmień konto

- Panel przyborów

- Zarządzaj zamówieniami

- Zarządzaj kanałami

- Książka adresowa

-

Powiadomienia

Oznacz wszystkie jako przeczytane - Zmień hasło

- Mój profil

- Wyloguj się

Pozycje

pomyślnie dodano do koszyka

Wyświetl koszyk

Wyświetl koszyk

Frezuj więcej za mniej dzięki naszym ofertom ograniczonym czasowo!

Kup teraz.

Pozycje

pomyślnie dodano do koszyka

Wyświetl koszyk

Wyświetl koszyk

Edytuj

Dodaj

Nazwa : {{SolutionName}}- Produkty

- /

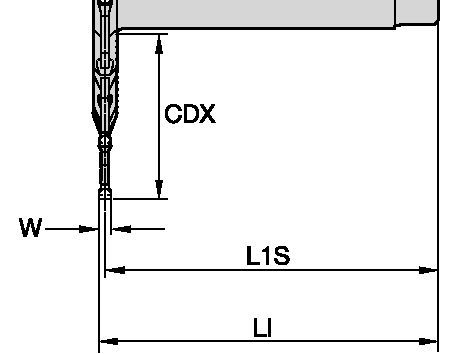

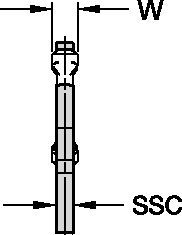

- Frezy KNS® do frezowania rowków • Wzmocniony korpus • Mocowanie nasadzane • Metryczne

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

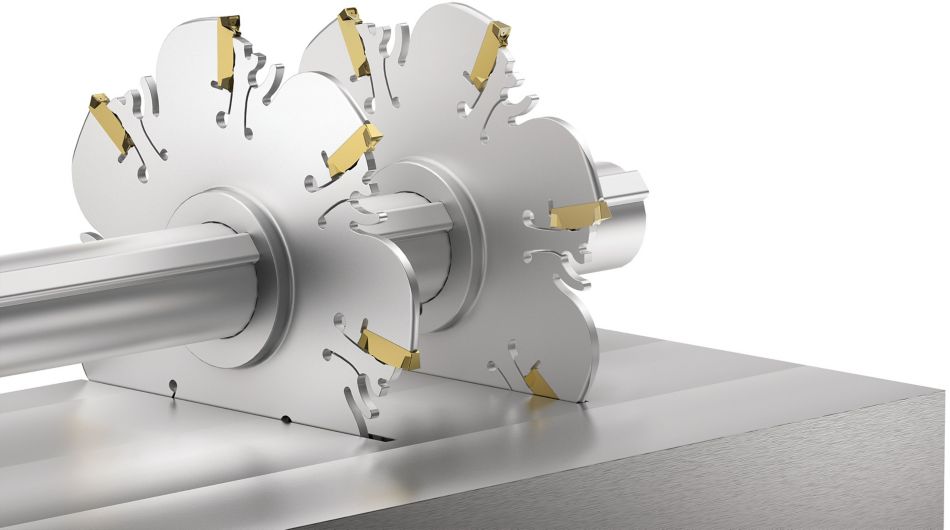

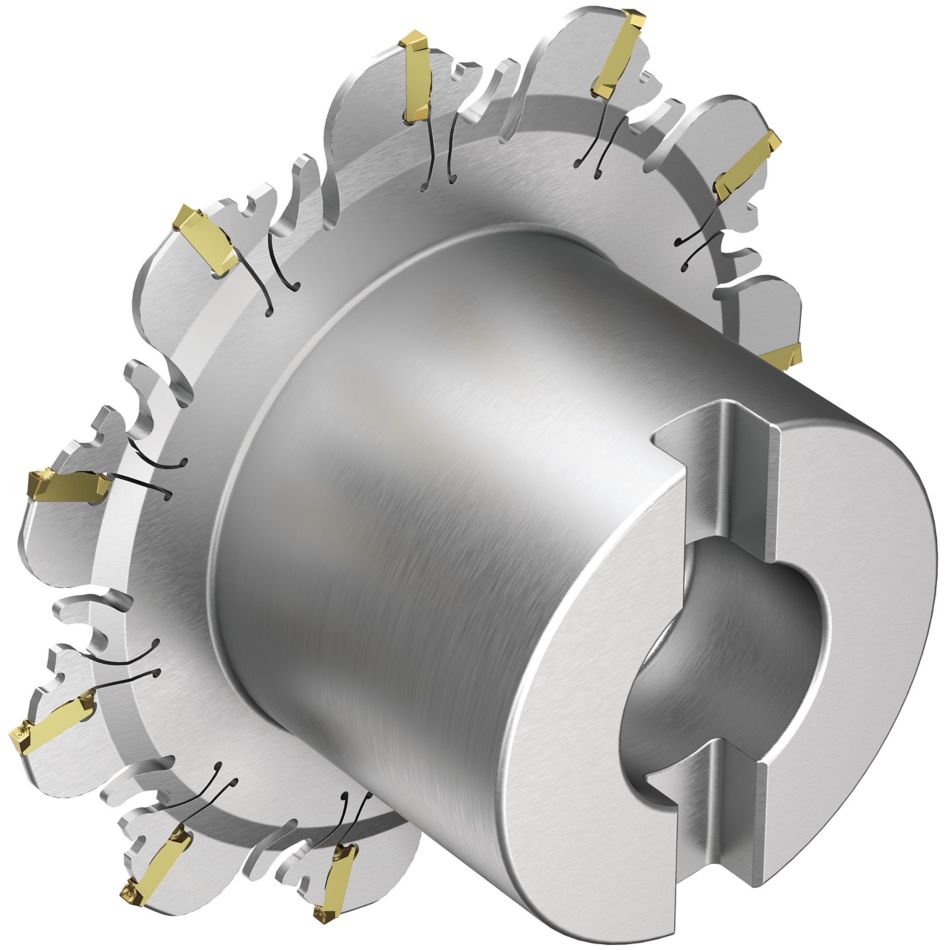

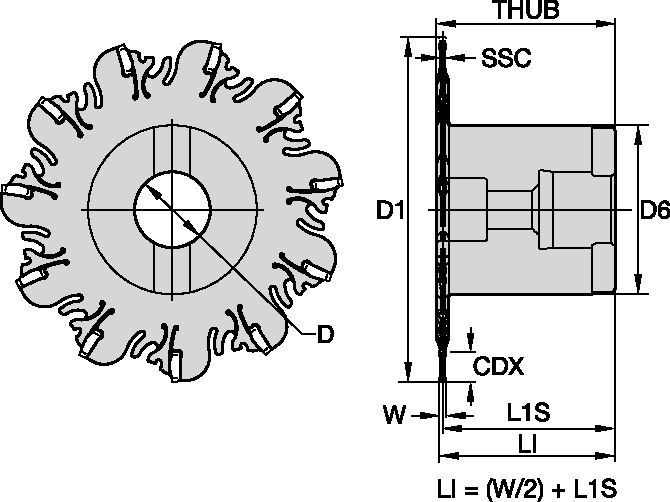

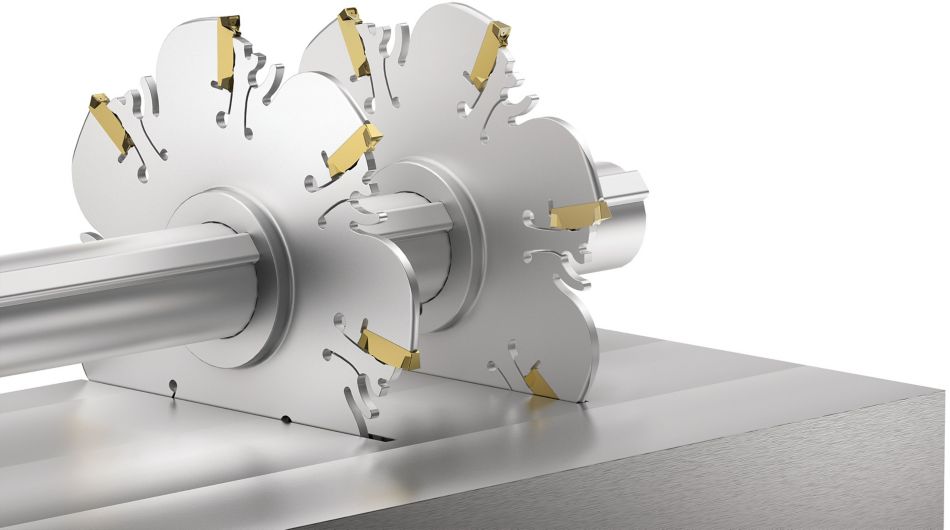

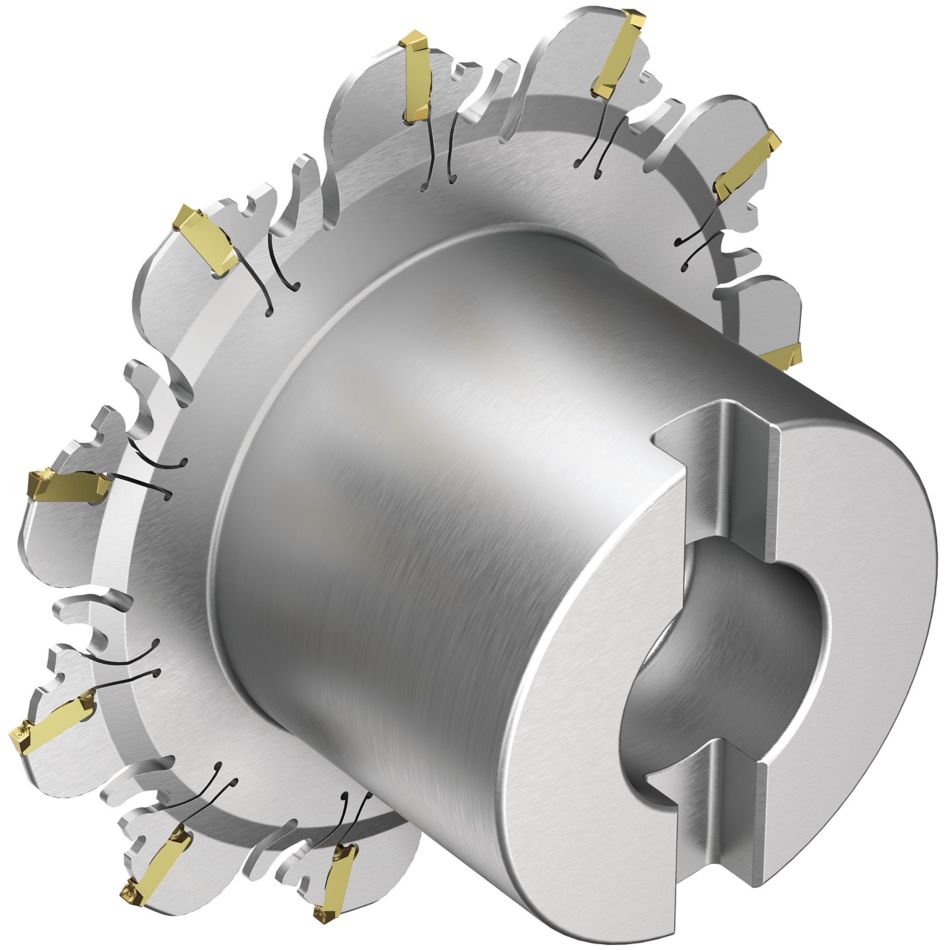

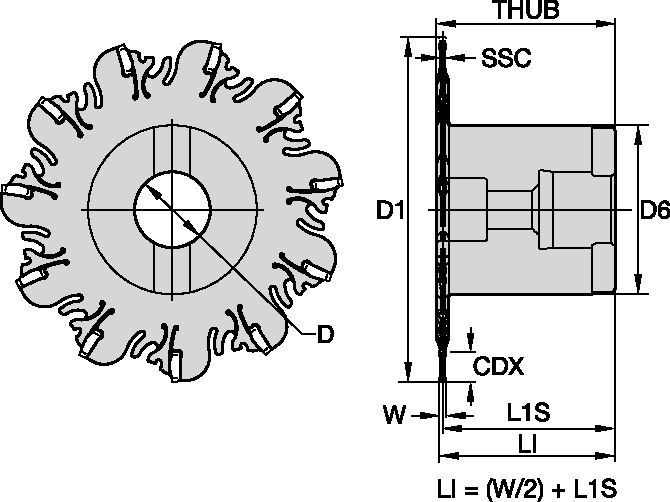

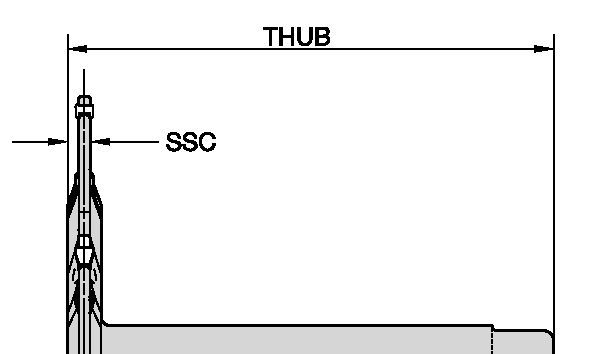

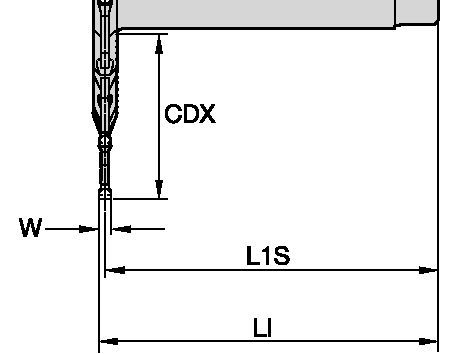

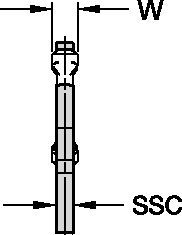

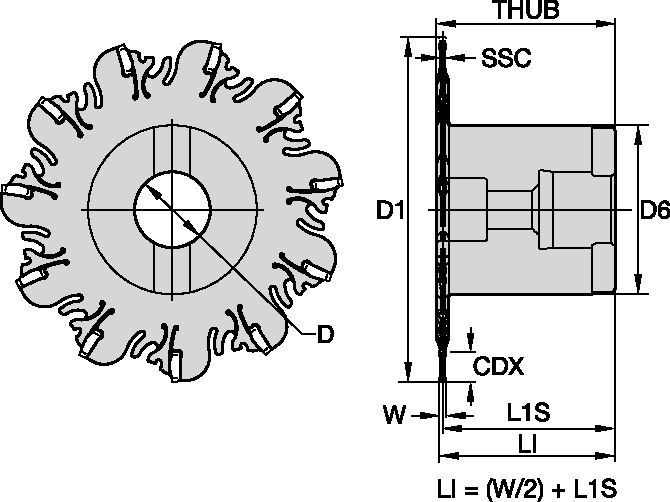

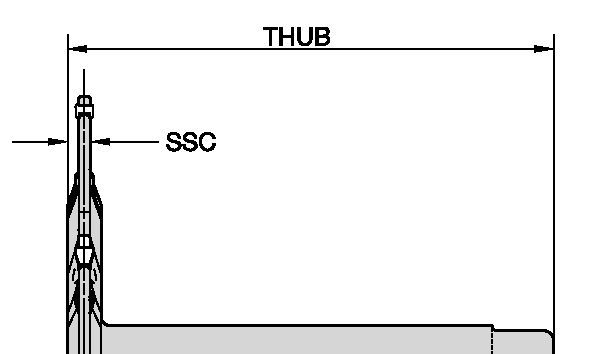

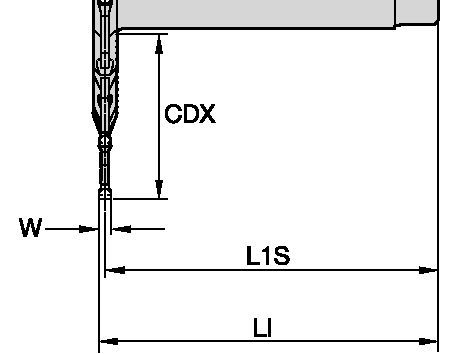

Frezy KNS® do frezowania rowków • Wzmocniony korpus • Mocowanie nasadzane • Metryczne

Frezy KNS® do frezowania rowków • Wzmocniony korpus • Mocowanie nasadzane

Właściwości i zalety

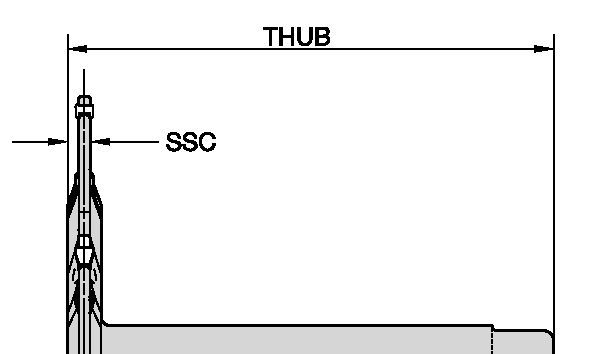

- Dwuwpustowa konstrukcja piasty do operacji wielokrotnego frezowania rowków.

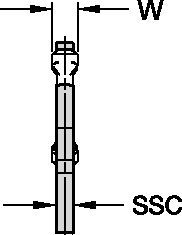

- Pozytywowa geometria SGP łamacza wióra w zastosowaniach od obróbki lekkiej do ciężkiej zapewnia płynną pracę narzędzia i skuteczne odprowadzanie wiórów.

- Podwójny rowek typu V oraz gniazdo utrzymują płytkę na miejscu i minimalizują bicie promieniowe.

- Wyjątkowy mechanizm samozaciskowy zapewnia łatwą wymianę płytek.

- Mocowanie nasadzane, wzmocniony korpus frezu.

Zastosowania

100055043

Slotting: Side

Side Milling/Shoulder Milling: Bottom Shouldering

| KNS® Slotting Cutter • Insert Selection Guide | ||||||

| Material Group | Light

|

General

|

Heavy

|

|||

| – | (Light geometry) | (Strong geometry) | ||||

| – | wear

|

<="" td=""> <="" td=""> | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1-P2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P3-P4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P5-P6 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| M1-M2 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| M3 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| K1-K2 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| K3 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| N1-N2 | – | – | .S..GP | KCU25 | – | – |

| N3 | – | – | .S..GP | KCU25 | – | – |

| S1-S2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S3 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| H1 | – | – | – | – | – | – |

Zalecane wyjściowe wartości posuwu [mm]

| KNS® Slotting Cutter • Recommended Starting Feeds [mm/th] | ||||||||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | |||||||||||

| 5% | 10% | 20% | 30–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| .S..GP | 0,13 | 0,28 | 0,35 | 0,09 | 0,20 | 0,32 | 0,07 | 0,15 | 0,32 | 0,06 | 0,12 | 0,30 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||||||||

| Light

|

General

|

Heavy

|

| KNS® Slotting Cutter • Recommended Starting Feeds [IPT] | ||||||||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | |||||||||||

| 5% | 10% | 20% | 30–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| .S..GP | 0.005 | 0.011 | 0.027 | 0.004 | 0.008 | 0.020 | 0.003 | 0.006 | 0.015 | 0.002 | 0.005 | 0.012 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||||||||

| Light

|

General

|

Heavy

|

Zalecane wyjściowe wartości prędkości skrawania [m/min]

| KNS® Slotting Cutter • Recommended Starting Speed [m/min] | ||||||||||

| Grade | KCU25 | KCPK30 | KMF | |||||||

| Chip Thickness hex mm | Min | Max | Min | Max | Min | Max | ||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 260 | 230 | 215 | 455 | 395 | 370 | 295 | 260 | 245 |

| 2 | 220 | 190 | 160 | 280 | 255 | 230 | 250 | 215 | 180 | |

| 3 | 200 | 170 | 140 | 255 | 230 | 205 | 230 | 195 | 160 | |

| 4 | 180 | 150 | 120 | 225 | 185 | 160 | 205 | 170 | 135 | |

| 5 | 150 | 135 | 120 | 190 | 170 | 150 | 170 | 155 | 135 | |

| 6 | 130 | 100 | 80 | 160 | 135 | 110 | 150 | 115 | 90 | |

| M | 1 | 210 | 170 | 135 | 205 | 185 | 155 | 195 | 170 | 155 |

| 2 | 170 | 150 | 110 | 185 | 160 | 140 | 175 | 150 | 125 | |

| 3 | 130 | 120 | 85 | 145 | 130 | 115 | 130 | 115 | 90 | |

| K | 1 | 270 | 220 | 170 | 295 | 265 | 240 | – | – | – |

| 2 | 230 | 190 | 160 | 235 | 210 | 190 | – | – | – | |

| 3 | 210 | 160 | 140 | 195 | 175 | 160 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 30 | 25 | 20 | – | – | – | 40 | 35 | 30 |

| 2 | 30 | 25 | 20 | – | – | – | 40 | 35 | 30 | |

| 3 | 40 | 30 | 20 | – | – | – | 50 | 40 | 30 | |

| 4 | 55 | 40 | 25 | 50 | 45 | 35 | 55 | 50 | 35 | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||

| KNS® Slotting Cutter • Recommended Starting Speed [SFM] | ||||||||||

| Grade | KCPK30 | KCPK30 | KMF | |||||||

| Chip Thickness hex Inch | Min | Max | Min | Max | Min | Max | ||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 855 | 755 | 705 | 1495 | 1295 | 1215 | 970 | 855 | 805 |

| 2 | 720 | 625 | 525 | 920 | 835 | 755 | 820 | 705 | 590 | |

| 3 | 655 | 560 | 460 | 835 | 755 | 675 | 755 | 640 | 525 | |

| 4 | 590 | 490 | 395 | 740 | 605 | 525 | 675 | 560 | 445 | |

| 5 | 490 | 445 | 395 | 625 | 560 | 490 | 560 | 510 | 445 | |

| 6 | 425 | 330 | 260 | 525 | 445 | 360 | 490 | 375 | 295 | |

| M | 1 | 690 | 560 | 445 | 675 | 605 | 510 | 640 | 560 | 510 |

| 2 | 560 | 490 | 360 | 605 | 525 | 460 | 575 | 490 | 410 | |

| 3 | 425 | 395 | 280 | 475 | 425 | 375 | 425 | 375 | 295 | |

| K | 1 | 885 | 720 | 560 | 970 | 870 | 785 | – | – | – |

| 2 | 755 | 625 | 525 | 770 | 690 | 625 | – | – | – | |

| 3 | 690 | 525 | 460 | 640 | 575 | 525 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 100 | 80 | 65 | – | – | – | 130 | 115 | 100 |

| 2 | 100 | 80 | 65 | – | – | – | 130 | 115 | 100 | |

| 3 | 130 | 100 | 65 | – | – | – | 165 | 130 | 100 | |

| 4 | 180 | 130 | 80 | 165 | 150 | 115 | 180 | 165 | 115 | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||