Produkt podobny do:

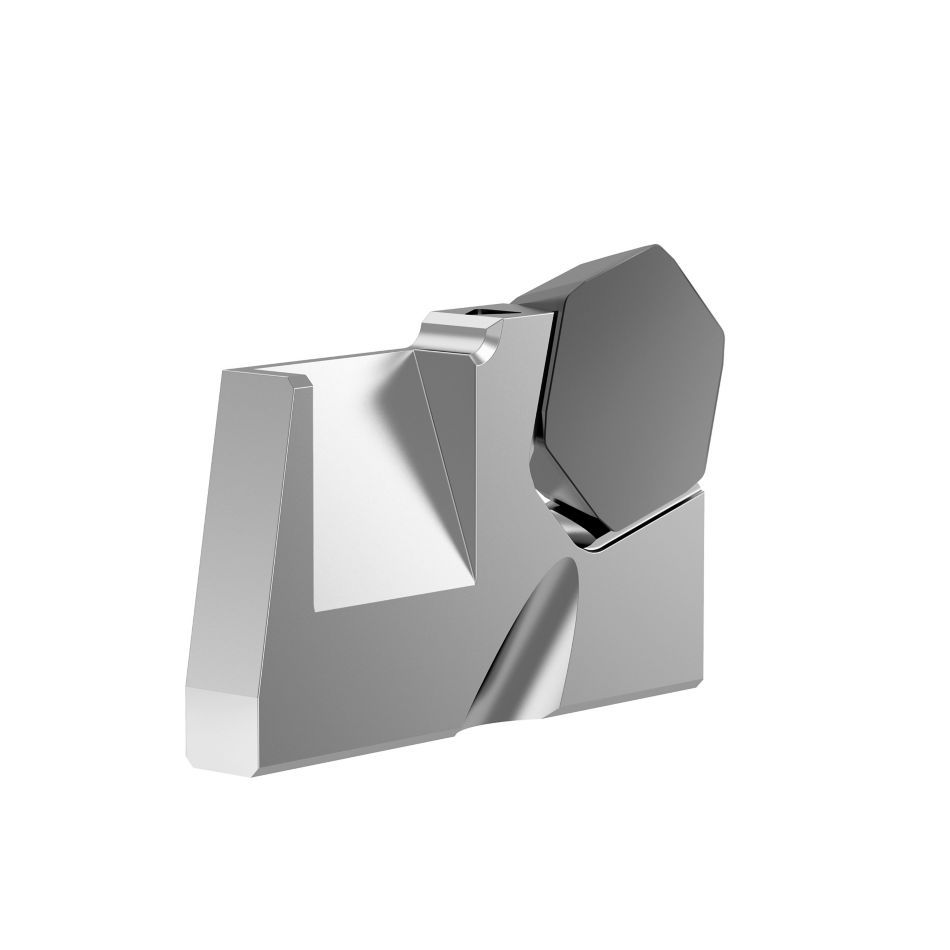

KCFM 45 • Shell Mill Cutter Assembly with Cartridges • Metryczne

Głowice frezarskie • Obróbka wykańczająca

Nr materiału6224415

Nr katalogowy ISOKCFM100R08HD07W2ASNr katalogowy ANSIKCFM100R08HD07W2AS

- K Cast Iron

Face Milling

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Podsumowanie

- Parametry skrawania

- Do pobrania

- Pasujace produkty - strona maszyny

- Pasujace produkty - strona przedmiotu obrabianego

- Części zamienne

- Opinia

- Q&A

| Nr materiału | 6224415 |

| Nr katalogowy ISO | KCFM100R08HD07W2AS |

| Nr katalogowy ANSI | KCFM100R08HD07W2AS |

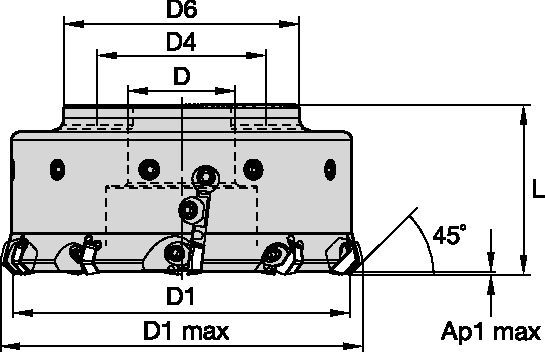

| [D1] Effective Cutting Diameter | 100 mm |

| [D1] Effective Cutting Diameter | 3.937 in |

| [D1MAX] Maximum Cutting Diameter | 109.53 mm |

| [D1MAX] Maximum Cutting Diameter | 4.312 in |

| [D] Adapter / Shank / Bore Diameter | 32 mm |

| [D] Adapter / Shank / Bore Diameter | 1.26 in |

| [D6] Hub Diameter | 101.4 mm |

| [D6] Hub Diameter | 3.992 in |

| [L] Overall Length | 50 mm |

| [L] Overall Length | 1.968 in |

| [AP1MAX] 1st Maximum Cutting Depth | 1.09 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .043 in |

| Number of Inserts | 8 |

| Number of Adjustable Inserts | 2 |

| Weight Kilograms | 2.45 |

| Max RPM | 8400 |

Materiały przedmiotu obrabianego

- Cast Iron

Zastosowania

Face Milling

Milling - Side and Face

Właściwości i zalety

- Niższe siły skrawania dzięki pozytywnej geometrii płytek sześciokątnych.

- Dostępne w gatunkach PCBN, ceramicznych i węglikowych.

- Osiągnij wyższe prędkości i wydajność dzięki materiałom ceramicznym i PCBN.

- * Ap1 maks. = 1mm z wiperem kaseta dla płytek wykańczających SD12.

- * Ap1 maks. = 3mm z kasetami półwykańczającymi dla płytek HD07.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

Dobór płytek

Poradnik doboru płytek

| – | Fine Finishing | Semi-Finishing | ||

| Material Group | Option 1: CBN | Option 2: Coated Carbide | Option 1: Advanced Material | Option 2: Coated Carbide |

| K1 | .S..R KBK50 | .E..R KC514M | .S..R KY3500/KBK50 | .E..R KC514M |

| K3 | – | .E..R KC514M | – | .E..R KC514M |

Posuwy

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| -SR | 0,06 | 0,12 | -SR | |||||||||||||

| -ER | 0,10 | 0,18 | -ER | |||||||||||||

| Fine Finishing | Semi-Finishing | Roughing |

Prędkości

| Material Group | KC514M | KBK50 | KY3500 | |||||||

| K | 1 | 950 | 625 | 445 | 3935 | 2625 | 1970 | 3165 | 2870 | 2560 |

| 2 | 740 | 525 | 375 | 3935 | 2625 | 1970 | 2495 | 2245 | 2085 | |

| 3 | 625 | 445 | 360 | 3935 | 2625 | 1970 | 2100 | 1870 | 1705 | |

| Material Group | KC514M | KBK50 | KY3500 | |||||||

| K | 1 | 760 | 500 | 355 | – | – | – | – | – | – |

| 2 | 590 | 420 | 300 | – | – | – | – | – | – | |

| 3 | 500 | 355 | 290 | – | – | – | – | – | – | |