Welcome

Please confirm your preferences

Update Preferences

Предложения по продукции

Product Family suggestions

Kennametal At Your Service

Have a Product Specific Question?

See a full list of Global Service Professionals by expertise area

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Уведомления

Отметить все как прочитанные - Favorites

- Change Password

- My Profile

- Logout

Позиции

успешно добавлено в корзину

View Cart

View Cart

Kennametal At Your Service

Have a Product Specific Question?

See a full list of Global Service Professionals by expertise area

Позиции

успешно добавлено в корзину

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- продукты

- /

- BF Combination Tool • Insert • R904

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

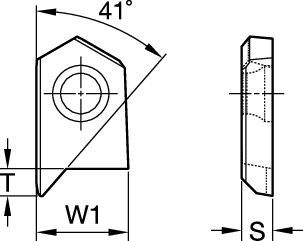

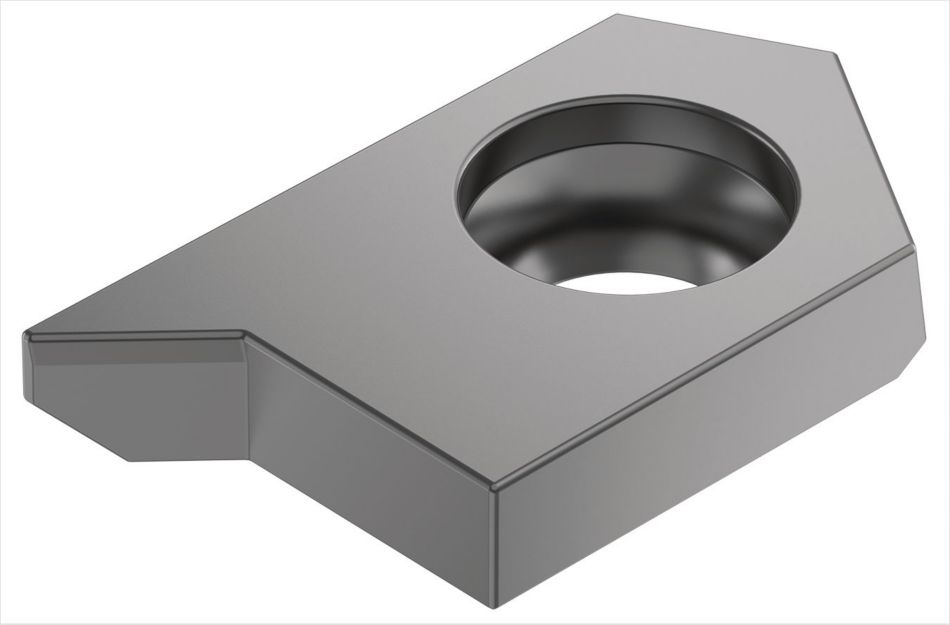

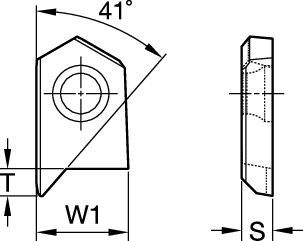

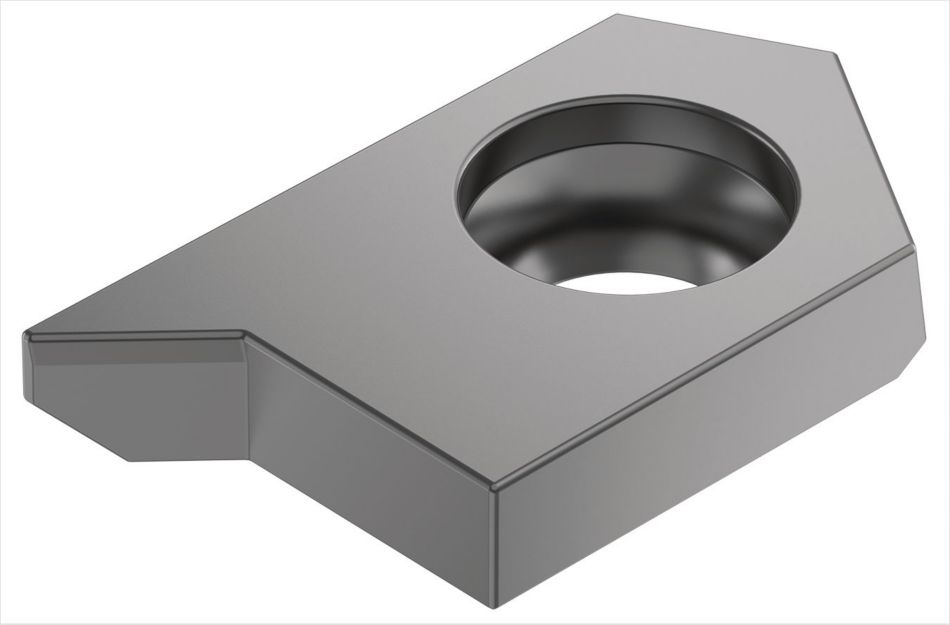

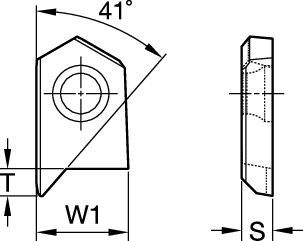

BF Combination Tool • Insert • R904

Combination Tooling • Carbide Insert for BF System • 41° Chamfer and spot face

Характеристики и преимущества

- For chamfering and spot facing in one operation