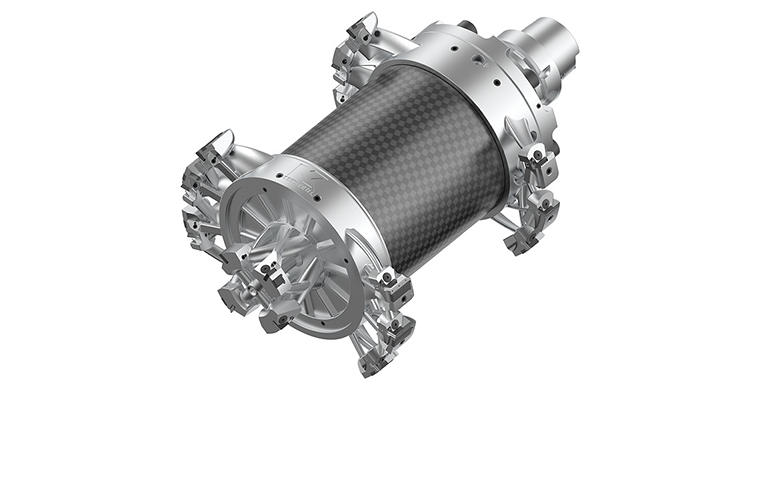

Изготовленный методом 3D-печати инструмент для обработки отверстий статора в алюминиевых корпусах двигателей электромобилей.

Эту версию инструмента отличают новая форма «лопастей», удерживающих пластины, увеличенный диаметр корпуса и общий вес 7,3 кг.

Этот сложный инструмент позволяет обрабатывать три отверстия большого диаметра за одну операцию, экономя время наладки и обработки для производителей автомобильных компонентов и обеспечивая высочайшую точность и качество поверхности.

Обрабатывая три диаметра за одну операцию, данный инструмент для растачивания статора обеспечивает соосность и концентричность получаемых отверстий, значительно сокращая длительность производственного цикла.

Легкий комбинированный инструмент, изготовленный методом 3D-печати, сокращает время наладки и подходит для использования на станках невысокой мощности.