A2™ • Отрезные пластины с одной режущей кромкой

Фильтры

Фильтры

Просмотреть фильтры в

Метрическая система

Дюймовая система

Workpiece Material

Workpiece Material

-

P Steel (149)

-

P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS (149)

-

P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS (149)

-

P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS (149)

-

P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS (149)

-

P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS (149)

-

P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS (149)

-

P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS (149)

-

-

M Stainless Steel (150)

-

M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS (150)

-

M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS (150)

-

M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS (150)

-

-

K Cast Iron (141)

-

K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS (141)

-

K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS (141)

-

K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS (141)

-

-

N Non-Ferrous Materials (141)

-

N1Wrought Aluminum (141)

-

N2Low-Silicon Aluminum Alloys and Magnesium Alloys Si <12.2% (140)

-

N4Copper, Brass, Zinc-based on machinability index range of 70-100 (141)

-

N5Nylon, Plastics, Rubbers, Phenolics, Resins, Fiberglass (140)

-

N6Carbon, Graphite Composites, CFRP (140)

-

-

S High-Temp Alloys (141)

-

S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS (141)

-

S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS (141)

-

S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS (141)

-

S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS (141)

-

Applications

Applications

-

Cut-Off (150)

Cutting Condition

Cutting Condition

-

Heavily Interrupted Cut (141)

-

Lightly Interrupted Cut (141)

-

Smooth Cut (150)

Tool Cutting Edge Angle

Tool Cutting Edge Angle

-

90.0 (35)

до

Connection Style

Connection Style

-

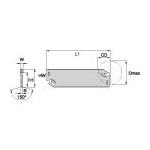

Cutoff Support Blade A1-A3 (35)

Cutting Edges Per Insert

Cutting Edges Per Insert

-

1.0 (150)

до

Internal Coolant Capability

Internal Coolant Capability

Over All Length [L]

Over All Length [L]

-

2.953 in (2)

-

3.386 in (7)

-

3.396 in (2)

-

3.551 in (2)

-

3.553 in (1)

-

3.946 in (1)

-

4.331 in (12)

-

4.339 in (2)

-

4.341 in (11)

-

4.343 in (1)

-

4.931 in (4)

-

5.315 in (3)

-

5.913 in (3)

-

5.915 in (4)

-

5.917 in (2)

-

10.242 in (1)

до

Over All Length [L]

Over All Length [L]

-

75.0 mm (2)

-

86.0 mm (7)

-

86.25 mm (2)

-

90.2 mm (2)

-

90.25 mm (1)

-

100.2 mm (1)

-

110.0 mm (12)

-

110.2 mm (2)

-

110.25 mm (11)

-

110.301 mm (1)

-

125.25 mm (4)

-

135.0 mm (3)

-

150.201 mm (3)

-

150.25 mm (4)

-

150.3 mm (2)

-

260.151 mm (1)

до

Corner Radius

Corner Radius

-

0.004 in (20)

-

0.006 in (11)

-

0.008 in (69)

-

0.012 in (49)

-

0.016 in (11)

до

Corner Radius

Corner Radius

-

0.1 mm (20)

-

0.151 mm (11)

-

0.2 mm (69)

-

0.301 mm (49)

-

0.4 mm (11)

до

Corner Chamfer

Corner Chamfer

-

0.0 mm (115)

до

Corner Chamfer

Corner Chamfer

-

0.0 in (115)

до

application

Minimum Depth of Cut

Minimum Feed

Minimum Feed

Grade Of Cutting Tool

Grade Of Cutting Tool

-

KC5025 (84)

-

KCU25 (91)

-

KMF (31)

-

KT315 (37)

Hand Of Tool

Hand Of Tool

-

L (7)

-

N (21)

-

R (7)

Wiper Insert

Wiper Insert

-

N (150)

F Dimension

F Dimension

-

1.25 mm (2)

до

F Dimension

F Dimension

-

0.049 in (2)

до

Maximum Axial Groove Diameter

Maximum Axial Groove Diameter

-

1.181 in (3)

-

1.339 in (1)

-

1.496 in (1)

-

1.655 in (9)

-

2.598 in (4)

до

Maximum Axial Groove Diameter

Maximum Axial Groove Diameter

-

30.0 mm (3)

-

34.0 mm (1)

-

38.0 mm (1)

-

42.0 mm (9)

-

66.0 mm (4)

до

Cutting Direction

Cutting Direction

-

E (35)

Rake Angle Style

Rake Angle Style

-

NEUTRAL (ZERO) (13)

-

POSITIVE-ZERO (20)

frontEnd

Clamp Style

Clamp Style

-

Y (35)

Cutting Width

Cutting Width

-

0.055 in (4)

-

0.061 in (5)

-

0.063 in (17)

-

0.088 in (38)

-

0.119 in (40)

-

0.12 in (13)

-

0.122 in (13)

-

0.157 in (17)

-

0.159 in (11)

-

0.197 in (10)

-

0.237 in (7)

-

0.315 in (5)

до

Cutting Width

Cutting Width

-

1.401 mm (4)

-

1.55 mm (5)

-

1.6 mm (17)

-

2.2 mm (38)

-

3.0 mm (40)

-

3.051 mm (13)

-

3.1 mm (13)

-

4.0 mm (17)

-

4.05 mm (11)

-

5.0 mm (10)

-

6.0 mm (7)

-

8.0 mm (5)

до

Insert Shape

Insert Shape

-

PRISMATIC (150)

Maximum Cutting Depth

Maximum Cutting Depth

-

0.591 in (2)

-

0.63 in (1)

-

0.669 in (1)

-

0.748 in (1)

-

0.787 in (1)

-

0.828 in (9)

-

0.984 in (3)

-

1.299 in (4)

-

1.575 in (6)

-

1.969 in (3)

-

2.362 in (3)

-

4.724 in (1)

до

Maximum Cutting Depth

Maximum Cutting Depth

-

15.0 mm (2)

-

16.0 mm (1)

-

17.0 mm (1)

-

19.0 mm (1)

-

20.0 mm (1)

-

21.0 mm (9)

-

25.0 mm (3)

-

33.0 mm (4)

-

40.0 mm (6)

-

50.0 mm (3)

-

60.0 mm (3)

-

120.0 mm (1)

до

insertGeometry

Shape

Shape

-

PRISMATIC (115)

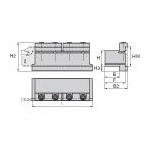

Insert Seat Size

Insert Seat Size

-

1 (16)

-

1B (2)

-

2 (29)

-

3 (33)

-

4 (18)

-

5 (8)

-

6 (5)

-

8 (4)

Cutting Tool Material

Cutting Tool Material

-

H T (37)

-

H W (141)

backEnd

Connection Type

Connection Type

-

CUTOFF BLADE (35)

Shank Height

Shank Height

-

0.748 in (2)

-

1.024 in (16)

-

1.26 in (16)

-

2.066 in (1)

до

Shank Height

Shank Height

-

19.0 mm (2)

-

26.0 mm (16)

-

32.0 mm (16)

-

52.475 mm (1)

до

Shank Width

Shank Width

-

0.07 in (3)

-

0.072 in (5)

-

0.095 in (7)

-

0.134 in (2)

-

0.174 in (2)

-

0.213 in (2)

-

0.276 in (1)

-

0.313 in (13)

до

Shank Width

Shank Width

-

1.776 mm (3)

-

1.8 mm (5)

-

2.401 mm (7)

-

3.401 mm (2)

-

4.4 mm (2)

-

5.4 mm (2)

-

7.0 mm (1)

-

7.95 mm (13)

до

No filters matching ""