Produkt podobny do:

LNUX-RRH

Płytki

Nr materiału5586626

Nr katalogowy ISOLNUX301940RRHNr katalogowy ANSILNUX301940RRH

- P Steel

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

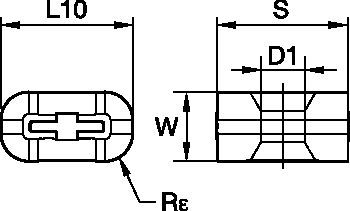

| Nr materiału | 5586626 |

| Nr katalogowy ISO | LNUX301940RRH |

| Nr katalogowy ANSI | LNUX301940RRH |

| Grade | KCP10B |

| [W] Insert Width | 12 mm |

| [W] Insert Width | .4724 in |

| [L10] Insert Cutting Edge Length | 30 mm |

| [L10] Insert Cutting Edge Length | 1.181 in |

| [S] Insert Thickness | 19.05 mm |

| [S] Insert Thickness | .75 in |

| [Rε] Corner Radius | 4 mm |

| [Rε] Corner Radius | .1575 in |

| [D1] Insert Hole Size | 6.35 mm |

| [D1] Insert Hole Size | .25 in |

Materiały przedmiotu obrabianego

- Steel

- Cast Iron

Właściwości i zalety

Kennametal zapewnia kompleksową ofertę standardowych płytek do obróbki zestawów kołowych. Płytki są dostępne w szerokim zakresie typów, rozmiarów i gatunków.

Wytaczanie kół — płytki z wprasowanym łamaczem wióra w płytkach okrągłych, kwadratowych, ośmiokątnych i regenerowanych.

Toczenie osi — płytki trójkątne i w kształcie rombu z łamaczem wióra.

Toczenie kół — płytki prostokątne i kwadratowe z wprasowanym łamaczem wióra lub bez niego.

Nadawanie kołom właściwego kształtu — okrągłe przyciski z otworem w środku umożliwiającym blokowanie.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use