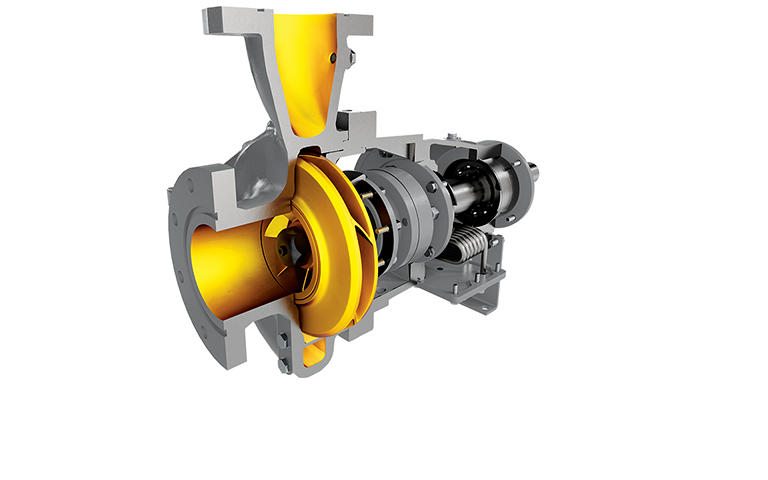

Yüksek Aşınmalı Uygulamalarda Kanıtlanmış Kaplama Çözümleri

Kennametal Conforma Clad™, eşsiz tekstil bazlı ve Ultraflex™ sulu çamur bazlı süreçlerimize iki endüstri standardı malzeme olan tungsten karbür ve Stellite™ kobalt bazlı alaşımı dahil etmiştir. Böylece, çeşitli endüstriler ve uygulamalar için çok çeşitli alt yapı malzemeleri ve geometrilerinde aşınmaya karşı üstün dirençli kaplamalar sunmamız mümkün hale gelmiştir.