Hoş Geldiniz

Lütfen tercihlerinizi onaylayın

Tercihleri Güncelle

Ürün Önerileri

Product Family suggestions

Merhaba, User Name

Seçtiğiniz Hesap:

There is an issue with your account. Please contact customer support.

Sold To Account

Hesabı Değiştir

Ship To Account

Hesabı Değiştir

- Kontrol Paneli

- Siparişleri Yönet

- Kanalları Yönet

- Adres Defteri

-

Bildirimler

Tümünü okundu olarak işaretle - Sık Kullanılanlar

- Parolayı Değiştir

- Profilim

- Oturumu Kapat

Ürün(ler)

sepete başarıyla eklendi

Sepeti Görüntüle

Sepeti Görüntüle

Limitli süre geçerli olan tekliflerimizle az ödeyip, daha çok frezeleyin.

Şimdi Satın Alın.

Ürün(ler)

sepete başarıyla eklendi

Sepeti Görüntüle

Sepeti Görüntüle

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Ürünler

- /

- Metal İşleme Takımları

- /

- Frezeleme

- /

- Katı Şaft Frezeleme

- /

- Yüksek performanslı karbür parmak frezeler

- /

- PCD End Mills

- /

- KenCut™ AQ • ALCR • Radyüslu • 2 Kanal • 2 x D • İçten soğutmalı • Düz şaft • Metrik

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

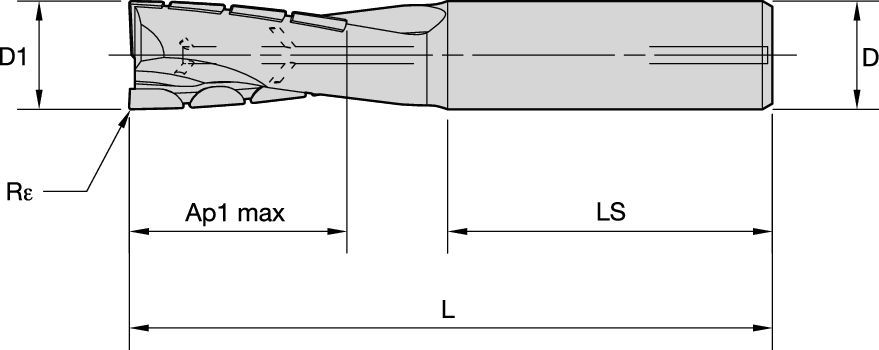

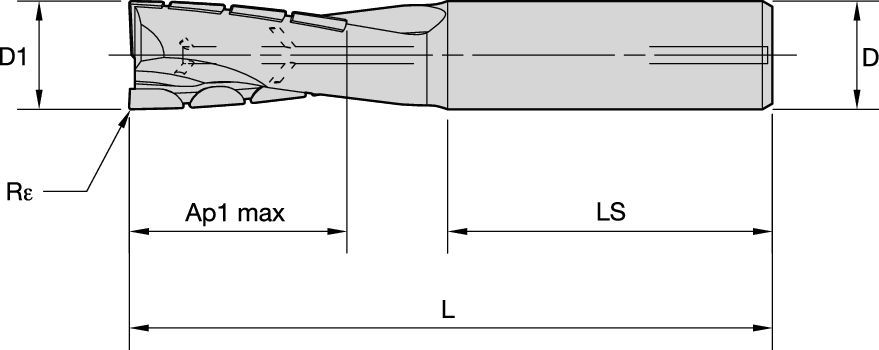

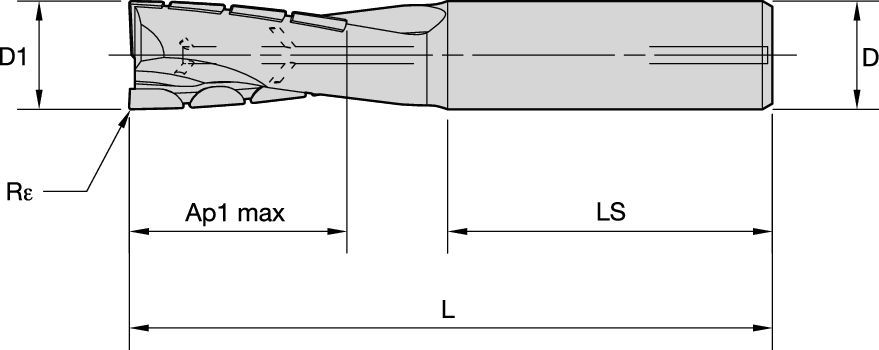

KenCut™ AQ • ALCR • Radyüslu • 2 Kanal • 2 x D • İçten soğutmalı • Düz şaft • Metrik

KenCut™ AQ PCD parmak freze alüminyumda kaba işleme ve hassas son işleme için uygun.

Özellikler ve avantajlar

- Yüksek hızda alüminyum işleme için çoklu kristalli elmaslı (PCD) parmak frezeler, işleme süresini önemli ölçüde kısaltır.

- PCD parmak frezeler, karbür parmak frezelere karşın on kata kadar daha yüksek verimlilik sağlar.

- Az miktarda yağlamaya uyumlu ve hazır durumda.

- Keskin kesme kenarları ve düşük sürtünmeli kesme sırtı yüzeyleri, yüksek kalitede hassas son işlemeli yüzey kalitesini garanti eder.

- Dalarak frezeleme ve eğimli işleme uygulamaları için merkezden kesme.

Kullanım ve uygulama alanları

Drilling

Trochoidal Milling

Slotting: Square End

100665610

Face Milling

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Pocketing

Side Milling/Shoulder Milling: Roughing

| Material

|

<="" td=""> <="" td=""> |  <="" td=""> <="" td=""> | KD1410 | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | |||||||

| A | B | Cutting Speed

|

D1

|

||||||||

| ap | ae | ap | Min | Max | mm | 12,0 | 16,0 | 20,0 | |||

| N | 1 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 3000 | Fz | 0,140 | 0,160 | 0,160 |

| 2 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 3000 | Fz | 0,140 | 0,160 | 0,160 | |

| 3 | 2 x D | 0,2 x D | 0,5 x D | 180 | – | 1400 | Fz | 0,120 | 0,140 | 0,140 | |

| 4 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 800 | Fz | 0,100 | 0,120 | 0,120 | |

| 5 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 1000 | Fz | 0,090 | 0,100 | 0,100 | |

| 6 | 2 x D | 0,2 x D | 0,5 x D | 150 | – | 800 | Fz | 0,060 | 0,080 | 0,080 | |

| 7 | 2 x D | 0,2 x D | 0,5 x D | 250 | – | 500 | Fz | 0,060 | 0,080 | 0,080 | |

| Material

|

<="" td=""> <="" td=""> |  <="" td=""> <="" td=""> | KD1410 | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | |||||||

| A | B | Cutting Speed

|

D1

|

||||||||

| ap | ae | ap | Min | Max | mm | 12,0 | 16,0 | 20,0 | |||

| N | 1 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 3000 | Fz | 0,140 | 0,160 | 0,160 |

| 2 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 3000 | Fz | 0,140 | 0,160 | 0,160 | |

| 3 | 2 x D | 0,2 x D | 0,5 x D | 180 | – | 1400 | Fz | 0,120 | 0,140 | 0,140 | |

| 4 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 800 | Fz | 0,100 | 0,120 | 0,120 | |

| 5 | 2 x D | 0,2 x D | 0,5 x D | 200 | – | 1000 | Fz | 0,090 | 0,100 | 0,100 | |

| 6 | 2 x D | 0,2 x D | 0,5 x D | 150 | – | 800 | Fz | 0,060 | 0,080 | 0,080 | |

| 7 | 2 x D | 0,2 x D | 0,5 x D | 250 | – | 500 | Fz | 0,060 | 0,080 | 0,080 | |