Hoş Geldiniz

Lütfen tercihlerinizi onaylayın

Tercihleri Güncelle

Ürün Önerileri

Product Family suggestions

Merhaba, User Name

Seçtiğiniz Hesap:

There is an issue with your account. Please contact customer support.

Sold To Account

Hesabı Değiştir

Ship To Account

Hesabı Değiştir

- Kontrol Paneli

- Siparişleri Yönet

- Kanalları Yönet

- Adres Defteri

-

Bildirimler

Tümünü okundu olarak işaretle - Sık Kullanılanlar

- Parolayı Değiştir

- Profilim

- Oturumu Kapat

Ürün(ler)

sepete başarıyla eklendi

Sepeti Görüntüle

Sepeti Görüntüle

Limitli süre geçerli olan tekliflerimizle az ödeyip, daha çok frezeleyin.

Şimdi Satın Alın.

Ürün(ler)

sepete başarıyla eklendi

Sepeti Görüntüle

Sepeti Görüntüle

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Ürünler

- /

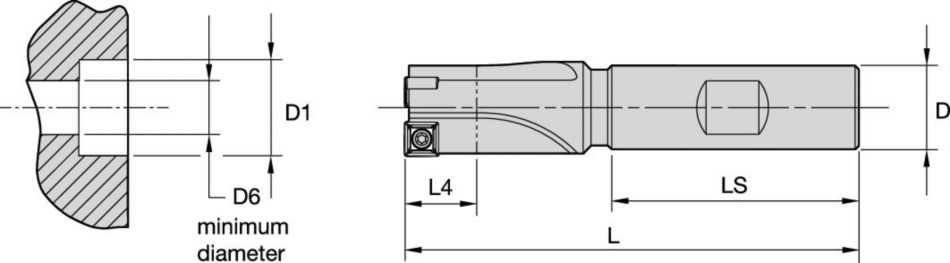

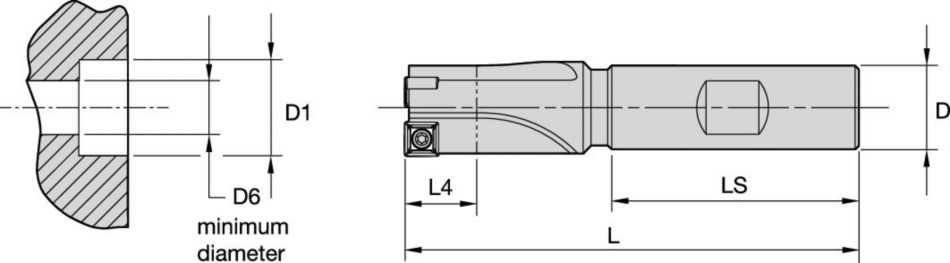

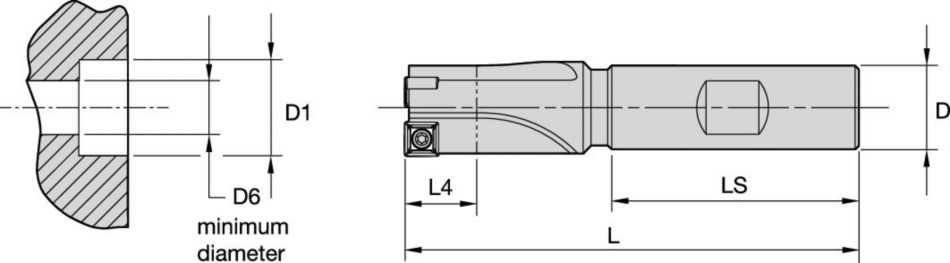

- S2S Weldon Shank • Inch

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

S2S Weldon Shank • Inch

CTR — Havşa

Özellikler ve avantajlar

- CTR Counterboring Tools are designed for high-production screw-head counterbores and similar counterboring operations.

- Extremely unequal insert positioning and flutes.

- S2 S inserts reduct additional drill operations to achieve a precise 90° bottom.

- Counterboring tool shipped with insert screws and Torx wrench.

Kullanım ve uygulama alanları

Flood Coolant: Drilling

Shank - Cylindrical Weldon

Counter Boring

Flute Configuration: 2

Flute Configuration: 3

| Material

|

Cutting Speed

|

Metric | |||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | SPHX06... Ø 15-22 | SPHX07 Ø 18-26 | SPHX09 Ø 23-37 | SPHX12 Ø 24-47 | |||||||

| P | 1 | 100 | 140 | 180 | mm/r | 0,19 | 0,31 | 0,23 | 0,33 | 0,24 | 0,38 | 0,3 | 0,5 |

| 2 | 90 | 125 | 160 | mm/r | 0,19 | 0,31 | 0,23 | 0,33 | 0,24 | 0,38 | 0,3 | 0,5 | |

| 3 | 80 | 110 | 140 | mm/r | 0,17 | 0,28 | 0,21 | 0,30 | 0,22 | 0,35 | 0,27 | 0,45 | |

| 4 | 70 | 100 | 120 | mm/r | 0,16 | 0,26 | 0,19 | 0,28 | 0,20 | 0,32 | 0,25 | 0,42 | |

| 5 | 60 | 85 | 100 | mm/r | 0,15 | 0,24 | 0,18 | 0,25 | 0,18 | 0,29 | 0,23 | 0,38 | |

| 6 | 50 | 70 | 90 | mm/r | 0,15 | 0,24 | 0,18 | 0,25 | 0,18 | 0,29 | 0,23 | 0,38 | |

| M | 1 | 60 | 70 | 90 | mm/r | 0,11 | 0,21 | 0,14 | 0,24 | 0,16 | 0,26 | 0,18 | 0,33 |

| 2 | 50 | 60 | 80 | mm/r | 0,11 | 0,21 | 0,14 | 0,24 | 0,16 | 0,26 | 0,18 | 0,33 | |

| 3 | 40 | 50 | 70 | mm/r | 0,09 | 0,17 | 0,11 | 0,19 | 0,13 | 0,21 | 0,14 | 0,26 | |

| K | 1 | 100 | 160 | 240 | mm/r | 0,28 | 0,52 | 0,35 | 0,65 | 0,35 | 0,65 | 0,42 | 0,78 |

| 2 | 80 | 120 | 160 | mm/r | 0,25 | 0,47 | 0,32 | 0,59 | 0,32 | 0,59 | 0,38 | 0,71 | |

| 3 | 70 | 100 | 130 | mm/r | 0,23 | 0,43 | 0,29 | 0,54 | 0,29 | 0,54 | 0,35 | 0,65 | |

| N | 1 | 160 | 240 | 300 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 |

| 2 | 160 | 220 | 280 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| 3 | 150 | 200 | 250 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| 4 | 120 | 180 | 240 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| 5 | 160 | 240 | 300 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| 6 | 200 | 300 | 400 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| S | 1 | 30 | 40 | 60 | mm/r | 0,14 | 0,18 | 0,17 | 0,21 | 0,19 | 0,23 | 0,21 | 0,29 |

| 2 | 25 | 35 | 50 | mm/r | 0,13 | 0,16 | 0,15 | 0,19 | 0,17 | 0,21 | 0,19 | 0,26 | |

| 3 | 20 | 30 | 40 | mm/r | 0,11 | 0,14 | 0,13 | 0,16 | 0,15 | 0,18 | 0,16 | 0,22 | |

| 4 | 20 | 25 | 35 | mm/r | 0,09 | 0,12 | 0,11 | 0,14 | 0,13 | 0,15 | 0,14 | 0,19 | |

| Material

|

Cutting Speed

|

Inch | |||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | SPHX06... Ø 15-22 | SPHX07 Ø 18-26 | SPHX09 Ø 23-37 | SPHX12 Ø 24-47 | |||||||

| P | 1 | 328 | 459 | 590 | IPR | 0.007 | 0.012 | 0.009 | 0.013 | 0.009 | 0.015 | 0.012 | 0.020 |

| 2 | 295 | 410 | 525 | IPR | 0.007 | 0.012 | 0.009 | 0.013 | 0.009 | 0.015 | 0.012 | 0.020 | |

| 3 | 262 | 361 | 459 | IPR | 0.007 | 0.011 | 0.008 | 0.012 | 0.009 | 0.014 | 0.011 | 0.018 | |

| 4 | 230 | 328 | 393 | IPR | 0.006 | 0.010 | 0.008 | 0.011 | 0.008 | 0.012 | 0.010 | 0.016 | |

| 5 | 197 | 279 | 328 | IPR | 0.006 | 0.009 | 0.007 | 0.010 | 0.007 | 0.012 | 0.009 | 0.015 | |

| 6 | 164 | 230 | 295 | IPR | 0.006 | 0.009 | 0.007 | 0.010 | 0.007 | 0.012 | 0.009 | 0.015 | |

| M | 1 | 197 | 230 | 295 | IPR | 0.004 | 0.008 | 0.006 | 0.009 | 0.006 | 0.010 | 0.007 | 0.013 |

| 2 | 164 | 197 | 262 | IPR | 0.004 | 0.008 | 0.006 | 0.009 | 0.006 | 0.010 | 0.007 | 0.013 | |

| 3 | 131 | 164 | 230 | IPR | 0.003 | 0.007 | 0.004 | 0.008 | 0.005 | 0.008 | 0.006 | 0.010 | |

| K | 1 | 328 | 525 | 787 | IPR | 0.011 | 0.020 | 0.014 | 0.026 | 0.014 | 0.026 | 0.017 | 0.031 |

| 2 | 262 | 393 | 525 | IPR | 0.010 | 0.019 | 0.013 | 0.023 | 0.013 | 0.023 | 0.015 | 0.028 | |

| 3 | 230 | 328 | 426 | IPR | 0.009 | 0.017 | 0.011 | 0.021 | 0.011 | 0.021 | 0.014 | 0.026 | |

| N | 1 | 525 | 787 | 984 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 |

| 2 | 525 | 721 | 918 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| 3 | 492 | 656 | 820 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| 4 | 393 | 590 | 787 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| 5 | 525 | 787 | 984 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| 6 | 656 | 984 | 1311 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| S | 1 | 98 | 131 | 197 | IPR | 0.006 | 0.007 | 0.007 | 0.008 | 0.007 | 0.009 | 0.008 | 0.011 |

| 2 | 82 | 115 | 164 | IPR | 0.005 | 0.006 | 0.006 | 0.008 | 0.007 | 0.008 | 0.008 | 0.010 | |

| 3 | 66 | 98 | 131 | IPR | 0.004 | 0.005 | 0.005 | 0.006 | 0.006 | 0.007 | 0.006 | 0.009 | |

| 4 | 66 | 82 | 115 | IPR | 0.004 | 0.005 | 0.004 | 0.006 | 0.005 | 0.006 | 0.006 | 0.008 | |