Bienvenue

Veuillez confirmer vos préférences

Mettre à jour les préférences

Suggestions de produit

Product Family suggestions

Nouveau client

Êtes-vous un nouveau client de Kennametal ? Créez un compte et commencez.

Créer un compteBonjour, User Name

Votre compte sélectionné :

Il y a un problème avec votre compte. Veuillez contacter le service client.

Compte Client Modifier le compte

Compte de livraison Modifier le compte

- Tableau de bord

- Gérer les commandes

- Gérer les canaux

- Carnet d’adresses

Notifications

Mark all as read- Modifier le mot de passe

- Mon profil

- Se déconnecter

Article(s) ajoutées avec succès au panier

Voir le panier

Voir le panier

Usinez plus pour moins cher avec nos promotions! Achetez maintenant

Article(s) ajoutées avec succès au panier

Voir le panier

Voir le panier

Édition de la Solution

Ajout de Solution

Nom de la Solution:{{SolutionName}}- Produits

- /

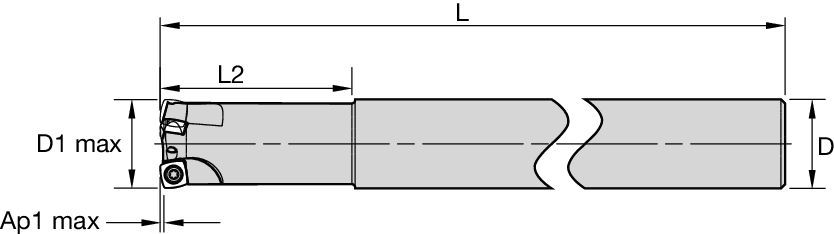

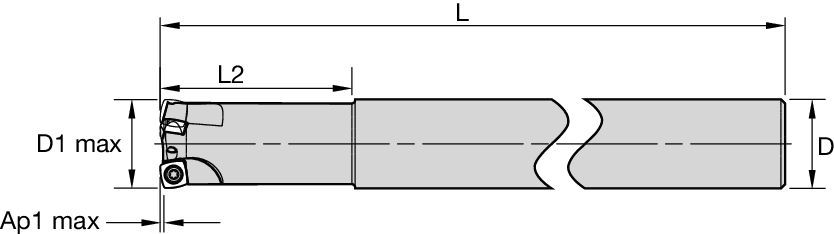

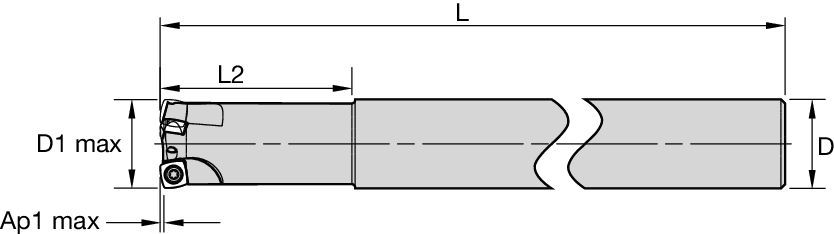

- 7792VXD09 Cylindrical Shank • Inch

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

7792VXD09 Cylindrical Shank • Inch

High-Feed Milling Cutters

Features and benefits

- Superior surface generation with integrated wiper facet.

- Maximum material removal rates.

- Suitable to machine HTA and titanium.

- Ultra-fine pitch cutters available to increase material removal rates, especially on high-temp alloys.

- Positive design to support lower cutting forces and long overhang usage.

- Ramping and plunge milling capabilities.

Uses and application

Spiral Circular

Slotting: Shoulder

Surfaçage

Fraisage hélicoïdal

Ramping : Ébauche

Queue — Cylindrique Classique

Fraisage — Arrosage interne

Usinage de poches

Lamage

Fraisage en plongée : Bout hémisphérique

Inclined Square End Mill

Guide de sélection des plaquettes • IC 09

| 7792 Series • IC09 • Insert Selection Guide | ||||||

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1-P2 | ...M41 | KCPM40 | …M41 | KCPM40 | …GP | KCPM40 |

| P3-P4 | ...M41 | KCPM40 | …D411 | SP6519 | …D41 | KCPM40 |

| P5-P6 | ...M41 | KCPM40 | ...D41 | SP6519 | ...D41 | X500 |

| M1-M2 | ...M41 | KCSM40 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| M3 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| K1-K2 | …M | KCK20B | …M | KCK20B | …D | KCPK30 |

| K3 | …M | KCK20B | …M | KCK20B | …D | KCPK30 |

| N1-N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1-S2 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| S3 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| S4 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| H1 | …M | KCKP10 | …M | KCKP10 | …D | KCPM40 |

| 7792 Series • IC09 • Recommended Starting Feeds [IPT] | |||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | ||||||

| DOC | 30% | 40–100% | |||||

| (Inch) | L | M | H | L | M | H | |

| .S..D | 0.06 | 0.010 | 0.022 | 0.035 | 0.009 | 0.020 | 0.032 |

| .S..D | 0.04 | 0.012 | 0.027 | 0.042 | 0.011 | 0.024 | 0.039 |

| .S..D | 0.03 | 0.014 | 0.031 | 0.049 | 0.013 | 0.028 | 0.044 |

| .E..D41 | 0.06 | 0.007 | 0.020 | 0.030 | 0.006 | 0.018 | 0.027 |

| .E..D41 | 0.04 | 0.009 | 0.024 | 0.036 | 0.008 | 0.022 | 0.033 |

| .E..D41 | 0.03 | 0.010 | 0.028 | 0.042 | 0.009 | 0.025 | 0.038 |

| .E..D411 | 0.06 | 0.007 | 0.020 | 0.030 | 0.006 | 0.018 | 0.027 |

| .E..D411 | 0.04 | 0.009 | 0.024 | 0.036 | 0.008 | 0.022 | 0.033 |

| .E..D411 | 0.03 | 0.010 | 0.028 | 0.042 | 0.009 | 0.025 | 0.038 |

| .S..GP | 0.06 | 0.010 | 0.022 | 0.035 | 0.009 | 0.020 | 0.032 |

| .S..GP | 0.04 | 0.012 | 0.026 | 0.042 | 0.011 | 0.024 | 0.038 |

| .S..GP | 0.03 | 0.014 | 0.030 | 0.048 | 0.013 | 0.028 | 0.044 |

| .S...M | 0.06 | 0.010 | 0.022 | 0.035 | 0.009 | 0.020 | 0.032 |

| .S...M | 0.04 | 0.012 | 0.027 | 0.042 | 0.011 | 0.024 | 0.039 |

| .S..M | 0.03 | 0.014 | 0.031 | 0.049 | 0.013 | 0.028 | 0.044 |

| .E..M41 | 0.06 | 0.007 | 0.020 | 0.030 | 0.006 | 0.018 | 0.027 |

| .E...M41 | 0.04 | 0.009 | 0.024 | 0.036 | 0.008 | 0.022 | 0.033 |

| .E..M41 | 0.03 | 0.010 | 0.028 | 0.042 | 0.009 | 0.025 | 0.038 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..D721 | .015 | .047 | .083 | .010 | .033 | .057 | .008 | .024 | .042 | .007 | .021 | .036 | .006 | .019 | .033 | .E..D721 |

| .E..D41 | .018 | .053 | .083 | .013 | .038 | .057 | .010 | .028 | .042 | .009 | .024 | .036 | .008 | .022 | .033 | .E..D41 |

| .E..D411 | .018 | .053 | .083 | .013 | .038 | .057 | .010 | .028 | .042 | .009 | .024 | .036 | .008 | .022 | .033 | .E..D411 |

| .S..D | .026 | .059 | .098 | .019 | .041 | .067 | .014 | .031 | .049 | .012 | .027 | .042 | .011 | .024 | .039 | .S..D |

| .S..GP | .026 | .058 | .097 | .019 | .041 | .067 | .014 | .030 | .049 | .012 | .026 | .042 | .011 | .024 | .038 | .S..GP |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..D721 | .017 | .054 | .097 | .012 | .038 | .066 | .009 | .028 | .048 | .008 | .024 | .042 | .007 | .022 | .038 | .E..D721 |

| .E..D41 | .021 | .062 | .097 | .015 | .043 | .066 | .011 | .032 | .048 | .010 | .028 | .042 | .009 | .025 | .038 | .E..D41 |

| .E..D411 | .021 | .062 | .097 | .015 | .043 | .066 | .011 | .032 | .048 | .010 | .028 | .042 | .009 | .025 | .038 | .E..D411 |

| .S..D | .030 | .069 | .115 | .021 | .048 | .078 | .016 | .035 | .056 | .014 | .031 | .049 | .013 | .028 | .044 | .S..D |

| .S..GP | .030 | .068 | .114 | .021 | .047 | .077 | .016 | .035 | .056 | .014 | .030 | .048 | .013 | .028 | .044 | .S..GP |

| 7792 Series • IC09 • Recommended Starting Feeds for Plunging [IPT] | ||||

| Insert Geometry |  | Programmed Feed per Tooth (fz) | ||

| L | M | H | ||

| .S..D | 0.004 | 0.009 | 0.014 | |

| .E..D41 | 0.003 | 0.008 | 0.012 | |

| .E..D411 | 0.003 | 0.008 | 0.012 | |

| .S..GP | 0.004 | 0.009 | 0.014 | |

| .S..M | 0.004 | 0.009 | 0.014 | |

| .E..M41 | 0.003 | 0.008 | 0.012 | |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | ||||

| Light | General | Heavy |

Vitesses de départ recommandées [m/mn]

| 7792 Series IC09 • Recommended Starting Speed [m/min] | ||||||||||||||||||||||||||||||||||

| Grade | KC522M | KC725M | KCK15 | KCPK30 | KCKP10 | KCK20B | KCPM40 | KCSM40 | SP6519 | X400 | X500 | |||||||||||||||||||||||

| Chip Thickness hex mm | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 330 | 285 | 270 | 260 | 230 | 215 | – | – | – | 455 | 395 | 370 | 300 | 295 | 260 | – | – | – | 295 | 260 | 245 | 350 | 320 | 300 | 295 | 215 | 130 | 260 | 190 | 120 | 270 | 200 | 130 |

| 2 | 275 | 240 | 200 | 220 | 190 | 160 | – | – | – | 280 | 255 | 230 | 310 | 275 | 240 | – | – | – | 250 | 215 | 180 | 300 | 270 | 220 | 260 | 190 | 115 | 230 | 170 | 105 | 240 | 280 | 115 | |

| 3 | 255 | 215 | 175 | 200 | 170 | 140 | – | – | – | 255 | 230 | 205 | 275 | 240 | 205 | – | – | – | 230 | 195 | 160 | 280 | 240 | 195 | 230 | 165 | 100 | 200 | 150 | 95 | 210 | 155 | 100 | |

| 4 | 225 | 185 | 150 | 180 | 150 | 120 | – | – | – | 225 | 185 | 160 | 240 | 205 | 160 | – | – | – | 205 | 170 | 135 | 240 | 205 | 165 | 175 | 125 | 75 | 150 | 110 | 70 | 160 | 120 | 75 | |

| 5 | 185 | 170 | 150 | 150 | 135 | 120 | – | – | – | 190 | 170 | 150 | 205 | 160 | 125 | – | – | – | 170 | 155 | 135 | 200 | 180 | 160 | 140 | 105 | 70 | – | – | – | 130 | 100 | 70 | |

| 6 | 165 | 125 | 100 | 130 | 100 | 80 | – | – | – | 160 | 135 | 110 | 160 | 125 | 110 | – | – | – | 150 | 115 | 90 | 180 | 140 | 100 | 120 | 85 | 50 | – | – | – | 110 | 80 | 50 | |

| M | 1 | 205 | 180 | 165 | 170 | 150 | 135 | – | – | – | 205 | 185 | 155 | – | – | – | – | – | – | 195 | 170 | 155 | 260 | 210 | 185 | 270 | 195 | 115 | – | – | – | 250 | 185 | 115 |

| 2 | 185 | 160 | 130 | 155 | 130 | 110 | – | – | – | 185 | 160 | 140 | – | – | – | – | – | – | 175 | 150 | 125 | 235 | 180 | 145 | 235 | 170 | 105 | – | – | – | 220 | 160 | 100 | |

| 3 | 140 | 120 | 95 | 115 | 100 | 80 | – | – | – | 145 | 130 | 115 | – | – | – | – | – | – | 130 | 115 | 90 | 175 | 145 | 110 | 195 | 140 | 85 | – | – | – | 180 | 130 | 80 | |

| K | 1 | 230 | 205 | 185 | – | – | – | 420 | 385 | 340 | 295 | 265 | 240 | 410 | 330 | 240 | 360 | 290 | 245 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 180 | 160 | 150 | – | – | – | 335 | 295 | 275 | 235 | 210 | 190 | 280 | 245 | 190 | 280 | 230 | 195 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 150 | 135 | 120 | – | – | – | 280 | 250 | 230 | 195 | 175 | 160 | 240 | 195 | 160 | 210 | 175 | 140 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 50 | 40 | 25 | 55 | 40 | 20 | – | – | – | 45 | 35 | 25 |

| 2 | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 55 | 40 | 25 | 45 | 35 | 20 | – | – | – | 45 | 30 | 20 | |

| 3 | 50 | 40 | 25 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | 65 | 45 | 30 | 55 | 40 | 25 | – | – | – | 50 | 40 | 25 | |

| 4 | 50 | 45 | 35 | 50 | 45 | 30 | – | – | – | 50 | 45 | 35 | – | – | – | – | – | – | 55 | 50 | 35 | 75 | 60 | 40 | 80 | 55 | 35 | – | – | – | 60 | 50 | 35 | |

| H | 1 | 120 | 90 | 70 | – | – | – | – | – | – | – | – | – | 140 | 110 | 90 | – | – | – | – | – | – | – | – | – | – | – | – | 95 | 70 | 45 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 80 | 60 | 35 | – | – | – | |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||||||||||||||

| 7792 Series IC09 • Recommended Starting Speed [SFM] | ||||||||||||||||||||||||||||||||||

| Grade | KC522M | KC725M | KCK15 | KCPK30 | KCKP10 | KCK20B | KCPM40 | KCSM40 | SP6519 | X400 | X500 | |||||||||||||||||||||||

| Chip Thickness hex Inch | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 1085 | 935 | 885 | 855 | 755 | 705 | – | – | – | 1495 | 1295 | 1215 | 985 | 970 | 855 | – | – | – | 970 | 855 | 805 | 1150 | 1050 | 985 | 970 | 705 | 425 | 855 | 625 | 395 | 885 | 655 | 425 |

| 2 | 900 | 785 | 655 | 720 | 625 | 525 | – | – | – | 920 | 835 | 755 | 1015 | 900 | 785 | – | – | – | 820 | 705 | 590 | 985 | 885 | 720 | 855 | 625 | 375 | 755 | 560 | 345 | 785 | 920 | 375 | |

| 3 | 835 | 705 | 575 | 655 | 560 | 460 | – | – | – | 835 | 755 | 675 | 900 | 785 | 675 | – | – | – | 755 | 640 | 525 | 920 | 785 | 640 | 755 | 540 | 330 | 655 | 490 | 310 | 690 | 510 | 330 | |

| 4 | 740 | 605 | 490 | 590 | 490 | 395 | – | – | – | 740 | 605 | 525 | 785 | 675 | 525 | – | – | – | 675 | 560 | 445 | 785 | 675 | 540 | 575 | 410 | 245 | 490 | 360 | 230 | 525 | 395 | 245 | |

| 5 | 605 | 560 | 490 | 490 | 445 | 395 | – | – | – | 625 | 560 | 490 | 675 | 525 | 410 | – | – | – | 560 | 510 | 445 | 655 | 590 | 525 | 460 | 345 | 230 | – | – | – | 425 | 330 | 230 | |

| 6 | 540 | 410 | 330 | 425 | 330 | 260 | – | – | – | 525 | 445 | 360 | 525 | 410 | 360 | – | – | – | 490 | 375 | 295 | 590 | 460 | 330 | 395 | 280 | 165 | – | – | – | 360 | 260 | 165 | |

| M | 1 | 675 | 590 | 540 | 560 | 490 | 445 | – | – | – | 675 | 605 | 510 | – | – | – | – | – | – | 640 | 560 | 510 | 855 | 690 | 605 | 885 | 640 | 375 | – | – | – | 820 | 605 | 375 |

| 2 | 605 | 525 | 425 | 510 | 425 | 360 | – | – | – | 605 | 525 | 460 | – | – | – | – | – | – | 575 | 490 | 410 | 770 | 590 | 475 | 770 | 560 | 345 | – | – | – | 720 | 525 | 330 | |

| 3 | 460 | 395 | 310 | 375 | 330 | 260 | – | – | – | 475 | 425 | 375 | – | – | – | – | – | – | 425 | 375 | 295 | 575 | 475 | 360 | 640 | 460 | 280 | – | – | – | 590 | 425 | 260 | |

| K | 1 | 755 | 675 | 605 | – | – | – | 1380 | 1265 | 1115 | 970 | 870 | 785 | 1345 | 1085 | 785 | 1180 | 950 | 805 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 590 | 525 | 490 | – | – | – | 1100 | 970 | 900 | 770 | 690 | 625 | 920 | 805 | 625 | 920 | 755 | 640 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 490 | 445 | 395 | – | – | – | 920 | 820 | 755 | 640 | 575 | 525 | 785 | 640 | 525 | 690 | 575 | 460 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 165 | 130 | 80 | 180 | 130 | 65 | – | – | – | 150 | 115 | 80 |

| 2 | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 180 | 130 | 80 | 150 | 115 | 65 | – | – | – | 150 | 100 | 65 | |

| 3 | 165 | 130 | 80 | 150 | 115 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 130 | 100 | 215 | 150 | 100 | 180 | 130 | 80 | – | – | – | 165 | 130 | 80 | |

| 4 | 165 | 150 | 115 | 165 | 150 | 100 | – | – | – | 165 | 150 | 115 | – | – | – | – | – | – | 180 | 165 | 115 | 245 | 195 | 130 | 260 | 180 | 115 | – | – | – | 195 | 165 | 115 | |

| H | 1 | 395 | 295 | 230 | – | – | – | – | – | – | – | – | – | 460 | 360 | 295 | – | – | – | – | – | – | – | – | – | – | – | – | 310 | 230 | 150 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 260 | 195 | 115 | – | – | – | |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||||||||||||||