Bienvenue

Veuillez confirmer vos préférences

Mettre à jour les préférences

Suggestions de produit

Product Family suggestions

Kennametal à votre service

Support Clients

Nouveau client

Êtes-vous un nouveau client de Kennametal ? Créez un compte et commencez.

Créer un compteBonjour, User Name

Votre compte sélectionné :

Il y a un problème avec votre compte. Veuillez contacter le service client.

Compte Client

Modifier le compte

Compte de livraison

Modifier le compte

- Tableau de bord

- Gérer les commandes

- Gérer les canaux

- Carnet d’adresses

-

Notifications

Mark all as read - Modifier le mot de passe

- Mon profil

- Se déconnecter

Article(s)

ajoutées avec succès au panier

Voir le panier

Voir le panier

Usinez plus pour moins cher avec nos promotions!

Achetez maintenant

Kennametal à votre service

Support Clients

Article(s)

ajoutées avec succès au panier

Voir le panier

Voir le panier

Édition de la Solution

Ajout de Solution

Nom de la Solution: {{SolutionName}}- Produits

- /

- Outils d’usinage des métaux

- /

- Fraisage

- /

- Fraises en carbure monobloc

- /

- Fraises en carbure monobloc hautes performances

- /

- Fraises en carbure monobloc hautes performances • HARVI™

- /

- HARVI™ I TE • Chanfreinée • 4 dents • Détallonée • Queue Weldon® • Métrique

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

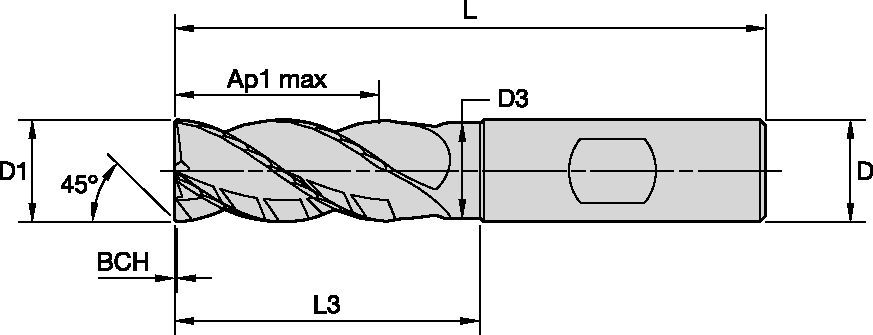

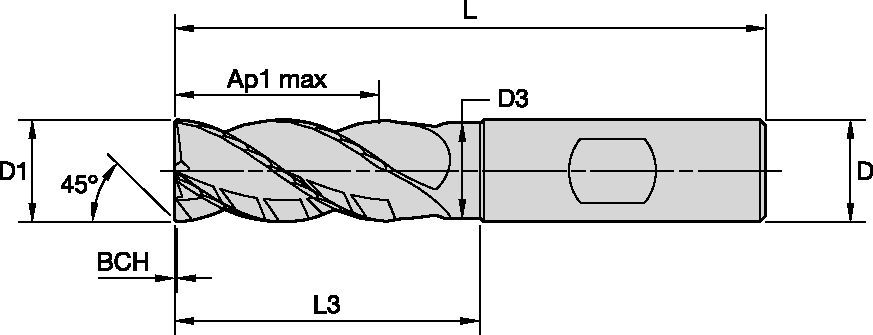

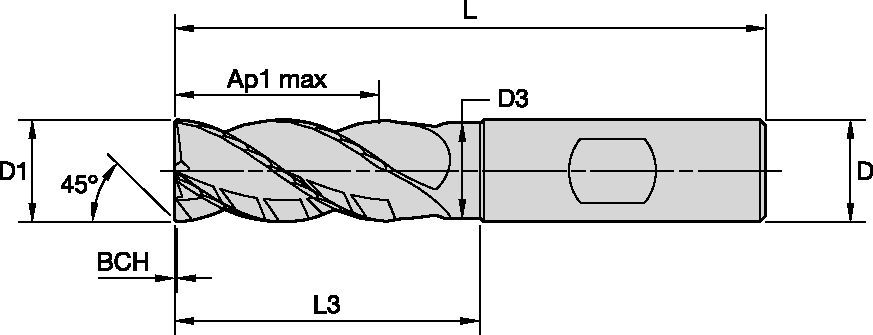

HARVI™ I TE • Chanfreinée • 4 dents • Détallonée • Queue Weldon® • Métrique

Fraise à quatre goujures HARVI™ I TE pour l'ébauche et la finition, couvrant la gamme la plus large d'applications et de matériaux

Features and benefits

- Fraise en carbure monobloc polyvalente pour les aciers, l'acier inoxydable, la fonte et les alliages haute température.

- Les fraises en carbure monobloc HARVI™ I TE couvrent diverses d'opérations, y compris le fraisage dynamique et les opérations de ramping extrêmes.

- Les fraises en carbure monobloc HARVI™ I TE sont synonymes d'enlèvement de métal maximal, de productivité maximale et de bénéfice maximal.

- Les fraises en carbure monobloc HARVI™ I TE sont dotées de goujures divisées asymétriques, d'une hélice variable, d'une face d'extrémité torsadée, d'une dépouille excentrée planée et de cannelures à copeaux dans les goujures.

- Coupe au centre pour opérations de plongée et de ramping.

Uses and application

Corner Style: Corner Chamfer

Trochoidal Milling

100147465

Fraisage hélicoïdal

Fraisage en plongée

Ramping : Ébauche

Rainurage : Bout plat

Fraisage de côté/avec épaulement : Léger chanfrein

Dimensions de l'outil : Configuration des goujures : 4

Queue — Cylindrique Weldon

Usinage de poches

Fraisage de côté/avec épaulement : Ébauche

Adjustment Factor for Feed and Speed Calculation • Metric

| Ae/D | 2% | 4% | 5% | 8% | 10% | 12% | 20% | 30% | 40% | 50% | 100% | |

| Speed factor | Kv | 2,1

|

1,6

|

1,6

|

1,6 | 1,4 | 1,38 | 1,3 | 1,2 | 1,1 | 1 | 0,9 |

| Feed factor | KFz | 3,58 | 2,56 | 2,3 | 1,84 | 1,67 | 1,54 | 1,25 | 1,09 | 1,02 | 1 | 1 |

| Ae/D | 2% | 4% | 5% | 8% | 10% | 12% | 20% | 30% | 40% | 50% | 100% | |

| Speed factor | Kv | 2.1

|

1.6

|

1.6

|

1.6 | 1.4 | 1.38 | 1.3 | 1.2 | 1.1 | 1 | 0.9 |

| Feed factor | KFz | 3.58 | 2.56 | 2.3 | 1.84 | 1.67 | 1.54 | 1.25 | 1.09 | 1.02 | 1 | 1 |

HARVI™ I TE • 4 goujures • Conseils d'utilisation • Métrique

| Ae/D | 2.00% | 4.00% | 5.00% | 8.00% | 10.00% | 20.00% | 30.00% | 40.00% | 50.00% | |

| Speed factor | Kv | 2 | 1.5 | 1.45 | 1.4 | 1.35 | 1.25 | 1.2 | 1 | 1 |

| Feed factor | KFz | 2.4 | 2.3 | 2.2 | 2 | 1.7 | 1.25 | 1.02 | 1 | 1 |

<="" td=""> <="" td=""> |  <="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||||||||||||

| Side Milling (A) and Slotting (B) | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | ||||||||||||||||||||||

| KCPM15/KCSM15 | D1

|

||||||||||||||||||||||

| A | B | Cutting Speed

|

|||||||||||||||||||||

| Material

|

ap | ae | ap | Min | Max | mm | 2,0 | 2,5 | 3,0 | 3,5 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | ||

| P | 0 | 1,5 x D | 0,5 x D | 1,25 x D | 150 | – | 200 | fz | 0,011 | 0,013 | 0,016 | 0,027 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 |

| 1 | 1,5 x D | 0,5 x D | 1,25 x D | 150 | – | 200 | fz | 0,011 | 0,013 | 0,016 | 0,027 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 | |

| 2 | 1,5 x D | 0,5 x D | 1,25 x D | 140 | – | 190 | fz | 0,011 | 0,013 | 0,016 | 0,027 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 | |

| 3 | 1,5 x D | 0,5 x D | 1,25 x D | 120 | – | 160 | fz | 0,009 | 0,011 | 0,013 | 0,022 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 | |

| 4 | 1,5 x D | 0,5 x D | 1,25 x D | 90 | – | 150 | fz | 0,008 | 0,010 | 0,012 | 0,021 | 0,024 | 0,030 | 0,036 | 0,049 | 0,059 | 0,069 | 0,077 | 0,084 | 0,091 | 0,097 | 0,107 | |

| 5 | 1,5 x D | 0,5 x D | 1,25 x D | 60 | – | 100 | fz | 0,007 | 0,009 | 0,011 | 0,018 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 6 | 1,5 x D | 0,5 x D | 1,25 x D | 50 | – | 75 | fz | 0,006 | 0,008 | 0,009 | 0,016 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |

| M | 1 | 1,5 x D | 0,5 x D | 1,25 x D | 90 | – | 115 | fz | 0,009 | 0,011 | 0,013 | 0,022 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 |

| 2 | 1,5 x D | 0,5 x D | 1,25 x D | 60 | – | 80 | fz | 0,007 | 0,009 | 0,011 | 0,018 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 3 | 1,5 x D | 0,5 x D | 1,00 x D | 60 | – | 70 | fz | 0,006 | 0,008 | 0,009 | 0,016 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |

| K | 1 | 1,5 x D | 0,5 x D | 1,00 x D | 120 | – | 150 | fz | 0,011 | 0,013 | 0,016 | 0,027 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 |

| 2 | 1,5 x D | 0,5 x D | 1,00 x D | 110 | – | 140 | fz | 0,009 | 0,011 | 0,013 | 0,022 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 | |

| 3 | 1,5 x D | 0,5 x D | 1,00 x D | 110 | – | 130 | fz | 0,007 | 0,009 | 0,011 | 0,018 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| S | 1 | 1,5 x D | 0,3 x D | 0,75 x D | 50 | – | 90 | fz | 0,009 | 0,011 | 0,013 | 0,022 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 |

| 2 | 1,5 x D | 0,3 x D | 0,75 x D | 50 | – | 80 | fz | 0,007 | 0,009 | 0,011 | 0,018 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 3 | 1,5 x D | 0,5 x D | 0,50 x D | 25 | – | 40 | fz | 0,005 | 0,006 | 0,007 | 0,012 | 0,014 | 0,018 | 0,021 | 0,029 | 0,035 | 0,041 | 0,046 | 0,051 | 0,055 | 0,059 | 0,067 | |

| 4 | 1,5 x D | 0,5 x D | 1,25 x D | 50 | – | 60 | fz | 0,006 | 0,007 | 0,009 | 0,015 | 0,017 | 0,023 | 0,028 | 0,040 | 0,049 | 0,057 | 0,064 | 0,071 | 0,076 | 0,082 | 0,092 | |

| H | 1 | 1,5 x D | 0,5 x D | 1,00 x D | 80 | – | 140 | fz | 0,008 | 0,010 | 0,012 | 0,021 | 0,024 | 0,030 | 0,036 | 0,049 | 0,059 | 0,069 | 0,077 | 0,084 | 0,091 | 0,097 | 0,107 |

| 2 | 1,5 x D | 0,2 x D | 1,00 x D | 70 | – | 120 | fz | 0,006 | 0,008 | 0,009 | 0,016 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |