Bienvenue

Veuillez confirmer vos préférences

Mettre à jour les préférences

Suggestions de produit

Product Family suggestions

Nouveau client

Êtes-vous un nouveau client de Kennametal ? Créez un compte et commencez.

Créer un compteBonjour, User Name

Votre compte sélectionné :

Il y a un problème avec votre compte. Veuillez contacter le service client.

Compte Client Modifier le compte

Compte de livraison Modifier le compte

- Tableau de bord

- Gérer les commandes

- Gérer les canaux

- Carnet d’adresses

Notifications

Mark all as read- Modifier le mot de passe

- Mon profil

- Se déconnecter

Article(s) ajoutées avec succès au panier

Voir le panier

Voir le panier

Usinez plus pour moins cher avec nos promotions! Achetez maintenant

Article(s) ajoutées avec succès au panier

Voir le panier

Voir le panier

Édition de la Solution

Ajout de Solution

Nom de la Solution:{{SolutionName}}- Produits

- /

- LT-NR/L-60

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

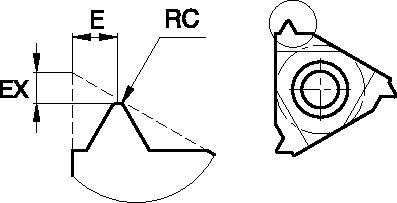

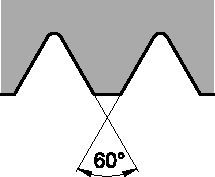

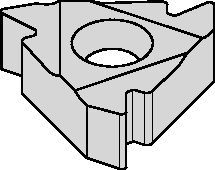

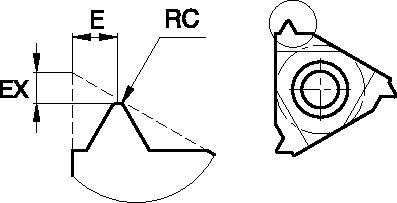

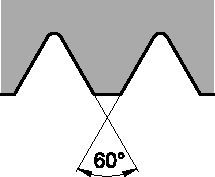

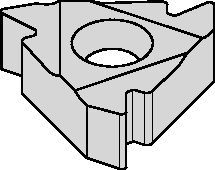

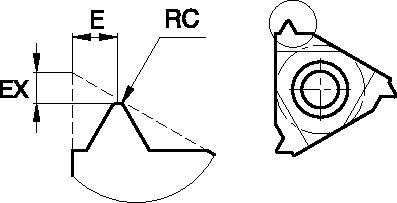

LT-NR/L-60

Plaquettes de filetage LT