ようこそ

設定をご確認ください

設定の更新

提案製品

Product Family suggestions

ソリューション編集

ソリューション追加

ソリューション名: {{SolutionName}}- 製品

- /

- DUO-LOCK™ • KenCut™ RR • Radiused • 3 Flutes • Inch

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

DUO-LOCK™ • KenCut™ RR • Radiused • 3 Flutes • Inch

Modular End Milling • RFDD Style • For MillTurn Machines and Lathes

特徴と利点

- RFDD Tips — High-performance roughing solution with excellent chip evacuation, especially in stainless steel.

- The short design and corner radii provide stability and reduce deflection forces.

- Ideally suited to perform long-reach applications on mill-turn machines, and driven tooling on lathes.

- The unique cutting geometry results in low cutting forces, requiring low power consumption.

使用法と用途

ランピング加工:ブランク

溝加工:スクエアエンド

側面加工/ショルダー加工:スクエアエンド

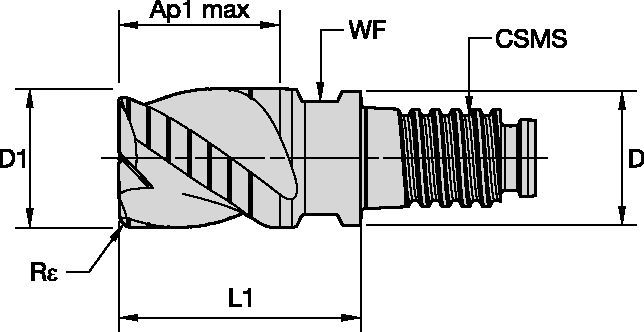

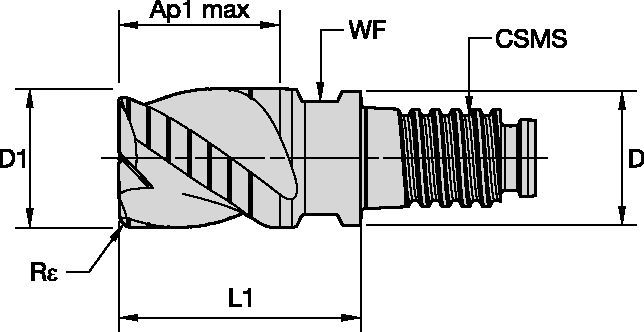

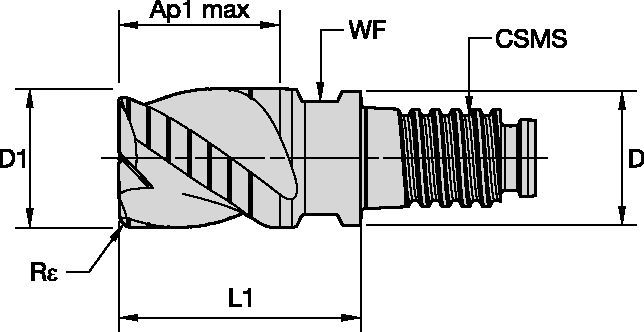

工具寸法:フルートの構造: 3

ねじれ角: 35°

コーナーのタイプ:コーナーR

| End Mill Tolerances | |

| D1 | tolerance d11 |

| 13/32

|

-0.002/-0.0063" |

| 23/32

|

-0.026/ -0.0077" |

RFDD • Inch

| Material

|

<="" td=""> <="" td=""> |  <="" td=""> <="" td=""> | straight short | conical medium | conical long | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | ||||||||||||

| A | B | KCPM15 | KCPM15 | KCPM15 | D1

|

|||||||||||||

| Cutting Speed

|

Cutting Speed

|

Cutting Speed

|

frac. | 3/8 | 1/2 | 5/8 | 3/4 | |||||||||||

| ap | ae | ap | Min | Max | Min | Max | Min | Max | dec. | 0.3750 | 0.5000 | 0.6250 | 0.7500 | |||||

| P | 0 | 0.75 x D | 0.5 x D | 0.5 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0037 |

| 1 | 0.75 x D | 0.5 x D | 0.5 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0037 | |

| 2 | 0.75 x D | 0.5 x D | 0.5 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0037 | |

| 3 | 0.75 x D | 0.5 x D | 0.5 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | 0.0019 | 0.0025 | 0.0029 | 0.0033 | |

| 4 | 0.75 x D | 0.4 x D | 0.5 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | 0.0017 | 0.0022 | 0.0026 | 0.0029 | |

| 5 | 0.75 x D | 0.5 x D | 0.5 x D | 200 | – | 330 | 170 | – | 281 | 160 | – | 264 | IPT | 0.0016 | 0.0020 | 0.0023 | 0.0026 | |

| 6 | 0.75 x D | 0.4 x D | 0.5 x D | 160 | – | 250 | 136 | – | 213 | 128 | – | 200 | IPT | 0.0013 | 0.0016 | 0.0019 | 0.0021 | |

| M | 1 | 0.75 x D | 0.4 x D | 0.5 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | 0.0019 | 0.0025 | 0.0029 | 0.0033 |

| 2 | 0.75 x D | 0.4 x D | 0.5 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | 0.0016 | 0.0020 | 0.0023 | 0.0026 | |

| 3 | 0.75 x D | 0.4 x D | 0.5 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | 0.0013 | 0.0016 | 0.0019 | 0.0021 | |

| K | 1 | 0.75 x D | 0.5 x D | 0.5 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0037 |

| 2 | 0.75 x D | 0.5 x D | 0.5 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | 0.0019 | 0.0025 | 0.0029 | 0.0033 | |

| 3 | 0.75 x D | 0.4 x D | 0.5 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | 0.0016 | 0.0020 | 0.0023 | 0.0026 | |

| H | 1 | 0.75 x D | 0.2 x D | 0.3 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | 0.0017 | 0.0022 | 0.0026 | 0.0029 |