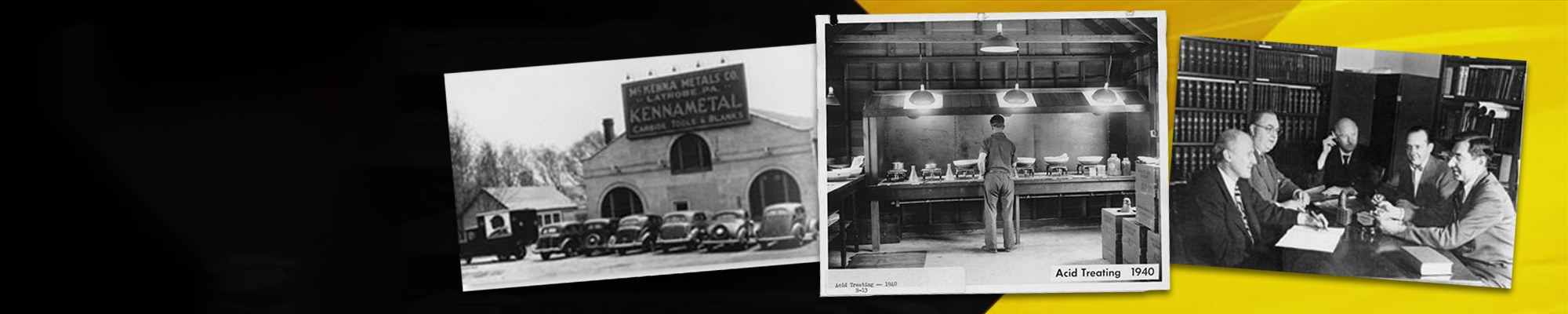

재료 과학의 선구자

Kennametal은 재료 과학의 장벽을 허물고 있습니다. 이 사명은 85년 전에 설립자이자 금속공학자인 Philip M. McKenna와 함께 시작되었으며 그 이후로도 계속되고 있습니다. 수년간의 연구 끝에 McKenna는 텅스텐-티타늄 초경 합금을 생산하여 강철 기계 가공에서 생산성 혁신을 이루었습니다. McKenna의 혁신을 통해 Kennametal 도구는 경쟁 제품보다 더 빠르고 오래 지속되어 운송부터 항공우주, 기계 금속에 이르기까지 다양한 산업의 고객이 이전에는 볼 수 없었던 속도로 작업할 수 있도록 지원합니다.