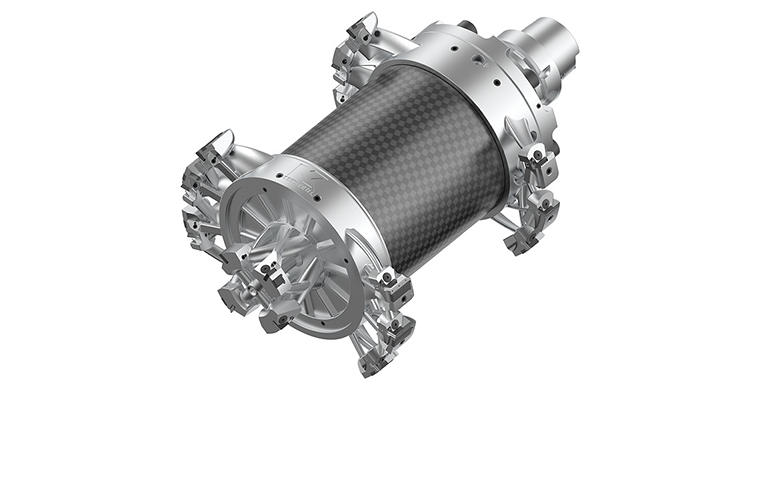

알루미늄 전자 모터 하우징의 가공을 위한 3D 인쇄형 스테이터 보어 공구.

이 버전의 도구는 새롭게 설계된 암 구조, 탄소 섬유로 만들어진 더 큰 센터 튜브, 총 7.3kg의 무게를 특징으로 합니다.

이 복합 공구를 사용하면 단 한 번의 작업으로 세 개의 큰 직경을 가공할 수 있어, 자동차 부품 제조업체의 셋업 시간과 가공 시간을 절감하고 최고의 정확도와 표면 품질을 제공합니다.

3개의 직경을 한 번에 가공할 수 있는 이 스테이터 보어 공구는 가공된 표면의 정렬과 동심도를 보장하면서 사이클 시간을 크게 단축합니다.

경량 3D 인쇄형 콤비네이션 공구를 사용하면 힘이 약한 기계에서도 더 빠른 공구 교환과 스핀업이 가능합니다.