5230VS09 Series • Helical Shell Mill • Metric

Shoulder milling cutter for multiple materials.

제품 번호5673801

ISO 카탈로그 ID5230VS09-A050Z4R80ANSI 카탈로그 ID5230VS09-A050Z04R80

- P Steel

- M Stainless Steel

- S High-Temp Alloys

- .caption

Slotting: Shoulder Profiling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

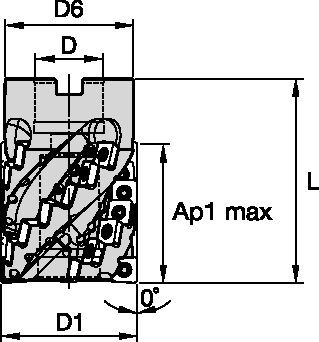

| 제품 번호 | 5673801 |

| ISO 카탈로그 ID | 5230VS09-A050Z4R80 |

| ANSI 카탈로그 ID | 5230VS09-A050Z04R80 |

| [D1] Effective Cutting Diameter | 50 mm |

| [D1] Effective Cutting Diameter | 1.9685 in |

| [D] Adapter / Shank / Bore Diameter | 27 mm |

| [D] Adapter / Shank / Bore Diameter | 1.063 in |

| [D6] Hub Diameter | 47.8 mm |

| [D6] Hub Diameter | 1.882 in |

| [L] Overall Length | 106 mm |

| [L] Overall Length | 4.173 in |

| [AP1MAX] 1st Maximum Cutting Depth | 80 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 3.15 in |

| Number of Inserts | 44 |

| [Z] Number of Flutes | 4 |

공작물 재료

- Steel

- Stainless Steel

- High-Temp Alloys

- .caption

사용 및 응용 분야

Slotting: Shoulder Profiling

특징 및 장점

- Adjustable coolant nozzles support chip evacuation and control heat in the cutting zone.

- Insert positioning provides smooth cutting action, resulting in lower power consumption.

- Well suited for titanium and high-temperature alloy machining.

이송 및 속도를 계산하려면 솔루션을 생성하세요.

솔루션 생성 후 이송 및 속도 아이콘을 선택하면 추천 값이 제공됩니다. 기계와 사양을 추가하여 사용자 정보를 지정하거나 슬라이더를 사용하여 조정할 수 있습니다.

이송량

권장 초기 이송[mm]

| 5230 VS09 • Recommended Starting Feeds [mm/th] | ||||||||||||

| 인서트 형상 | 반경 방향 절삭폭(ae) 비율에 따른 권장 초기 날당 이송(Fz) | |||||||||||

| 10% | 20% | 30% | 40–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| .E..422 | 0,09 | 0,33 | 0,54 | 0,07 | 0,25 | 0,40 | 0,06 | 0,22 | 0,35 | 0,06 | 0,20 | 0,32 |

| .E..423 | 0,12 | 0,38 | 0,63 | 0,09 | 0,28 | 0,47 | 0,08 | 0,25 | 0,41 | 0,07 | 0,23 | 0,38 |

| .E..41 | 0,14 | 0,43 | 0,68 | 0,11 | 0,32 | 0,51 | 0,09 | 0,28 | 0,44 | 0,08 | 0,25 | 0,41 |

| ...TN | 0,17 | 0,43 | 0,64 | 0,13 | 0,32 | 0,48 | 0,11 | 0,28 | 0,41 | 0,10 | 0,25 | 0,38 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||||||||

| 5230 VS09 • Recommended Starting Feeds [IPT] | ||||||||||||

| 인서트 형상 | 반경 방향 절삭폭(ae) 비율에 따른 권장 초기 날당 이송(Fz) | |||||||||||

| 10% | 20% | 30% | 40–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| .E..422 | 0.004 | 0.013 | 0.021 | 0.003 | 0.010 | 0.016 | 0.002 | 0.009 | 0.014 | 0.002 | 0.008 | 0.013 |

| .E..423 | 0.005 | 0.015 | 0.025 | 0.004 | 0.011 | 0.019 | 0.003 | 0.010 | 0.016 | 0.003 | 0.009 | 0.015 |

| .E..41 | 0.006 | 0.017 | 0.027 | 0.004 | 0.013 | 0.020 | 0.004 | 0.011 | 0.017 | 0.003 | 0.010 | 0.016 |

| ...TN | 0.007 | 0.017 | 0.025 | 0.005 | 0.013 | 0.019 | 0.004 | 0.011 | 0.016 | 0.004 | 0.010 | 0.015 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||||||||

속도

권장 초기 속도[m/min]

| 5720 Series • Recommended Starting Speed [m/min] | |||||||||||||

| 재종 | MP91M | KCSM40 | SP6519 | X500 | |||||||||

| 칩 두께 hex mm | 최소 | 최대 | 최소 | 최대 | 최소 | 최대 | 최소 | 최대 | |||||

| 소재 그룹 | 최대 | 초기값 | 최소 | 최대 | 초기값 | 최소 | 최대 | 초기값 | 최소 | 최대 | 초기값 | 최소 | |

| P | 1 | 345 | 245 | 140 | 350 | 320 | 300 | 295 | 215 | 130 | 270 | 200 | 130 |

| 2 | 305 | 215 | 120 | 300 | 270 | 220 | 260 | 190 | 115 | 240 | 280 | 115 | |

| 3 | 270 | 190 | 105 | 280 | 240 | 195 | 230 | 165 | 100 | 210 | 155 | 100 | |

| 4 | 205 | 145 | 80 | 240 | 205 | 165 | 175 | 125 | 75 | 160 | 120 | 75 | |

| 5 | – | – | – | 200 | 180 | 160 | 140 | 105 | 70 | 130 | 100 | 70 | |

| 6 | – | – | – | 180 | 140 | 100 | 120 | 85 | 50 | 110 | 80 | 50 | |

| M | 1 | – | – | – | 260 | 210 | 185 | 270 | 195 | 115 | 250 | 185 | 115 |

| 2 | – | – | – | 235 | 180 | 145 | 235 | 170 | 105 | 220 | 160 | 100 | |

| 3 | – | – | – | 175 | 145 | 110 | 195 | 140 | 85 | 180 | 130 | 80 | |

| K | 1 | 365 | 255 | 145 | – | – | – | – | – | – | – | – | – |

| 2 | 285 | 200 | 115 | – | – | – | – | – | – | – | – | – | |

| 3 | 260 | 185 | 105 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 50 | 40 | 25 | 55 | 40 | 20 | 45 | 35 | 25 |

| 2 | – | – | – | 55 | 40 | 25 | 45 | 35 | 20 | 45 | 30 | 20 | |

| 3 | – | – | – | 65 | 45 | 30 | 55 | 40 | 25 | 50 | 40 | 25 | |

| 4 | – | – | – | 75 | 60 | 40 | 80 | 55 | 35 | 60 | 50 | 35 | |

| H | 1 | 105 | 80 | 50 | – | – | – | – | – | – | – | – | – |

| 2 | 95 | 70 | 40 | – | – | – | – | – | – | – | – | – | |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||||||||

| 5720 Series • Recommended Starting Speed [SFM] | |||||||||||||

| 재종 | MP91M | KCSM40 | SP6519 | X500 | |||||||||

| Chip Thickness hex Inch | 최소 | 최대 | 최소 | 최대 | 최소 | 최대 | 최소 | 최대 | |||||

| 소재 그룹 | 최대 | 초기값 | 최소 | 최대 | 초기값 | 최소 | 최대 | 초기값 | 최소 | 최대 | 초기값 | 최소 | |

| P | 1 | 1130 | 805 | 460 | 1150 | 1050 | 985 | 970 | 705 | 425 | 885 | 655 | 425 |

| 2 | 1000 | 705 | 395 | 985 | 885 | 720 | 855 | 625 | 375 | 785 | 920 | 375 | |

| 3 | 885 | 625 | 345 | 920 | 785 | 640 | 755 | 540 | 330 | 690 | 510 | 330 | |

| 4 | 675 | 475 | 260 | 785 | 675 | 540 | 575 | 410 | 245 | 525 | 395 | 245 | |

| 5 | – | – | – | 655 | 590 | 525 | 460 | 345 | 230 | 425 | 330 | 230 | |

| 6 | – | – | – | 590 | 460 | 330 | 395 | 280 | 165 | 360 | 260 | 165 | |

| M | 1 | – | – | – | 855 | 690 | 605 | 885 | 640 | 375 | 820 | 605 | 375 |

| 2 | – | – | – | 770 | 590 | 475 | 770 | 560 | 345 | 720 | 525 | 330 | |

| 3 | – | – | – | 575 | 475 | 360 | 640 | 460 | 280 | 590 | 425 | 260 | |

| K | 1 | 1200 | 835 | 475 | – | – | – | – | – | – | – | – | – |

| 2 | 935 | 655 | 375 | – | – | – | – | – | – | – | – | – | |

| 3 | 855 | 605 | 345 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 165 | 130 | 80 | 180 | 130 | 65 | 150 | 115 | 80 |

| 2 | – | – | – | 180 | 130 | 80 | 150 | 115 | 65 | 150 | 100 | 65 | |

| 3 | – | – | – | 215 | 150 | 100 | 180 | 130 | 80 | 165 | 130 | 80 | |

| 4 | – | – | – | 245 | 195 | 130 | 260 | 180 | 115 | 195 | 165 | 115 | |

| H | 1 | 345 | 260 | 165 | – | – | – | – | – | – | – | – | – |

| 2 | 310 | 230 | 130 | – | – | – | – | – | – | – | – | – | |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||||||||

인서트 선택

| 5230 VS09 • Insert Selection Guide | ||||||

| 소재 그룹 | 경절삭 | 범용 | 중황삭 | |||

| – | (경절삭용 형상) | – | (중절삭용 형상) | |||

| – | 내마모성 |  | 인성 | |||

| – | 형상 | 재종 | 형상 | 재종 | 형상 | 재종 |

| P1–P2 | .E..422 | SP6519 | .E..41 | SP6519 | .E..41 | SP6519 |

| P3–P4 | .E..423 | SP6519 | .E..423 | SP6519 | ...TN | MP91M |

| P5–P6 | .E..41 | SP6519 | .E..423 | SP6519 | ...TN | SP6519 |

| M1–M2 | .E..422 | KCSM40 | .E..41 | KCSM40 | .E..423 | KCSM40 |

| M3 | .E..423 | KCSM40 | .E..423 | KCSM40 | ...TN | KCSM40 |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .E..422 | X500 | .E..41 | KCSM40 | .E..423 | KCSM40 |

| S3 | .E..422 | KCSM40 | .E..423 | KCSM40 | .E..41 | KCSM40 |

| S4 | .E..41 | X500 | .E..423 | X500 | ...TN | X500 |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use