Produkt podobny do:

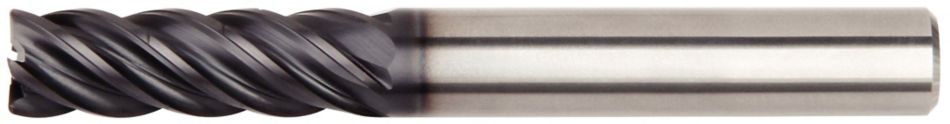

KOR5™ DS • Radiused • 5 Flutes • 3 x D • Weldon® Shank • Inch

KOR5™ DS Solid Carbide End Mill for Dynamic Milling of Steel and Stainless Steel

Nr materiału6769786

Nr katalogowy ISOKOR5RA0250R075HBR030Nr katalogowy ANSIKOR5RA0250R075HBR030

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Trochoidal Milling

Ramping: 5°

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 5

Shank - Cylindrical Weldon

Helix Angle: 40°

Corner Style: Corner Radius

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Nr materiału | 6769786 |

| Nr katalogowy ISO | KOR5RA0250R075HBR030 |

| Nr katalogowy ANSI | KOR5RA0250R075HBR030 |

| Grade | KC643M |

| Adapter Style Machine Side | Weldon |

| [Re] Corner Radius | 0.762 mm |

| [Re] Corner Radius | .03 in |

| [Z] Number of Flutes | 5 |

| [D1] Effective Cutting Diameter | 6.35 mm |

| [D1] Effective Cutting Diameter | .25 in |

| [D] Adapter / Shank / Bore Diameter | 6.35 mm |

| [D] Adapter / Shank / Bore Diameter | .25 in |

| [AP1MAX] 1st Maximum Cutting Depth | 19.05 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .75 in |

| [L] Overall Length | 63.5 mm |

| [L] Overall Length | 2.5 in |

Materiały przedmiotu obrabianego

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Zastosowania

Trochoidal Milling

Ramping: 5°

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 5

Shank - Cylindrical Weldon

Helix Angle: 40°

Corner Style: Corner Radius

Właściwości i zalety

- Designed for trochoidal milling with low radial engagement and full length of cut.

- With chip deformers for ideal chip evacuation at high surface quality.

- Proprietary flute form reduces vibrations and improves tool life.

- Helix angle tailored to minimize vibration and optimize tool life.

- Front end geometry designed for maximum tool life in helical and ramping operations.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

TechnicalInfo

KOR5™ DS • 5 Flutes • 3 x D • Adjustment factor table for feed calculation • Inch

| Ae/D1 | 0.50% | 1.00% | 1.50% | 2.00% | 4.00% | 5.00% | 8.00% | 10.00% | |

| Speed factor | Kv | 2.15 | 2.11 | 2.07 | 1.48 | 1.11 | 1.07 | 1.04 | 1.00 |

| Feed factor | KFz | 1.65 | 1.53 | 1.47 | 1.41 | 1.35 | 1.29 | 1.18 | 1.00 |

Parametry skrawania

KOR5™ DS • 5 Flutes • 3 x D • Application Data • Inch

| Malzeme grubu |  |  | |||||||||||

| Dik kenar frezeleme (A) | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||||

| A | KC643M | D1 | |||||||||||

| Kesme hızı | frac. | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||

| ap | ae | Min. | Maks. | dec. | .2500 | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 0 | 3 x D | 0.1 x D | 500 | – | 1440 | IPT | .0022 | .0033 | .0041 | .0047 | .0053 | .0059 |

| 1 | 3 x D | 0.1 x D | 500 | – | 1440 | IPT | .0022 | .0033 | .0041 | .0047 | .0053 | .0059 | |

| 2 | 3 x D | 0.1 x D | 460 | – | 1370 | IPT | .0022 | .0033 | .0041 | .0047 | .0053 | .0059 | |

| 3 | 3 x D | 0.1 x D | 400 | – | 1150 | IPT | .0018 | .0027 | .0035 | .0041 | .0046 | .0054 | |

| 4 | 3 x D | 0.1 x D | 300 | – | 1080 | IPT | .0017 | .0025 | .0031 | .0036 | .0040 | .0046 | |

| 5 | 3 x D | 0.1 x D | 200 | – | 720 | IPT | .0015 | .0022 | .0028 | .0033 | .0037 | .0043 | |

| 6 | 3 x D | 0.1 x D | 170 | – | 540 | IPT | .0012 | .0018 | .0023 | .0027 | .0030 | .0034 | |

| M | 1 | 3 x D | 0.1 x D | 300 | – | 830 | IPT | .0018 | .0027 | .0035 | .0041 | .0046 | .0054 |

| 2 | 3 x D | 0.1 x D | 200 | – | 580 | IPT | .0015 | .0022 | .0028 | .0033 | .0037 | .0043 | |

| 3 | 3 x D | 0.1 x D | 200 | – | 510 | IPT | .0012 | .0018 | .0023 | .0027 | .0030 | .0034 | |

| K | 1 | 3 x D | 0.1 x D | 400 | – | 1080 | IPT | .0022 | .0033 | .0041 | .0047 | .0053 | .0059 |

| 2 | 3 x D | 0.1 x D | 370 | – | 1010 | IPT | .0018 | .0027 | .0035 | .0041 | .0046 | .0054 | |

| 3 | 3 x D | 0.1 x D | 370 | – | 940 | IPT | .0015 | .0022 | .0028 | .0033 | .0037 | .0043 | |

| S | 1 | 3 x D | 0.1 x D | 170 | – | 650 | IPT | .0018 | .0027 | .0035 | .0041 | .0046 | .0054 |

| 2 | 3 x D | 0.1 x D | 80 | – | 580 | IPT | .0015 | .0022 | .0028 | .0033 | .0037 | .0043 | |

| 3 | 3 x D | 0.1 x D | 80 | – | 290 | IPT | .0010 | .0015 | .0018 | .0022 | .0025 | .0029 | |

| 4 | 3 x D | 0.1 x D | 170 | – | 430 | IPT | .0013 | .0020 | .0026 | .0030 | .0034 | .0040 | |

| H | 1 | 3 x D | 0.1 x D | 270 | – | 1010 | IPT | .0017 | .0025 | .0031 | .0036 | .0040 | .0046 |

| 2 | 3 x D | 0.1 x D | 230 | – | 870 | IPT | .0012 | .0018 | .0023 | .0027 | .0030 | .0034 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use

KOR™5DS

KOR™ Series End Mills: Solid End Mills for Dynamic Milling