Bem-vindo!

Confirme suas preferências

Atualizar preferências

Sugestões de produtos

Product Family suggestions

Kennametal ao seu serviço

Olá., User Name

Sua conta selecionada:

Existe um problema com a sua conta. Entre em contato com o suporte ao cliente.

Conta do vendedor

Alterar conta

Conta de entrega

Alterar conta

- Painel de controle

- Gerenciar pedidos

- Gerenciar canais

- Catálogo de endereços

-

Notificações

Marcar todas como lidas - Alterar senha

- Meu perfil

- Desconectar

Itens

adicionado com sucesso ao carrinho

Ver o carrinho

Ver o carrinho

Fresar mais por menos com nossas ofertas por tempo limitado!

Compre agora

Kennametal ao seu serviço

Itens

adicionado com sucesso ao carrinho

Ver o carrinho

Ver o carrinho

Editando solução

Adicionando solução

Nome da solução: {{SolutionName}}- Produtos

- /

- Insertos do chanfro BF • R900 S(T)F • Semiacabamento • CS5/KMF

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

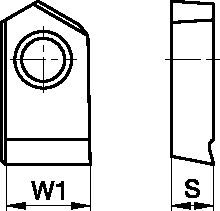

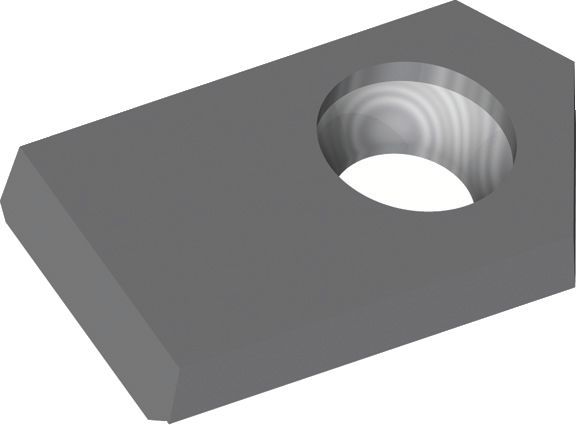

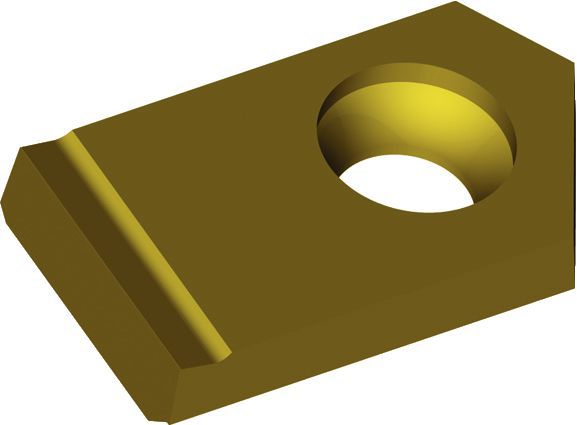

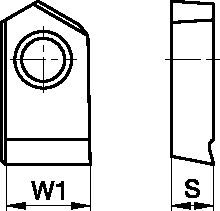

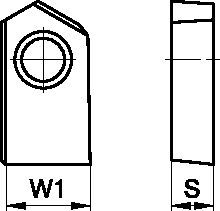

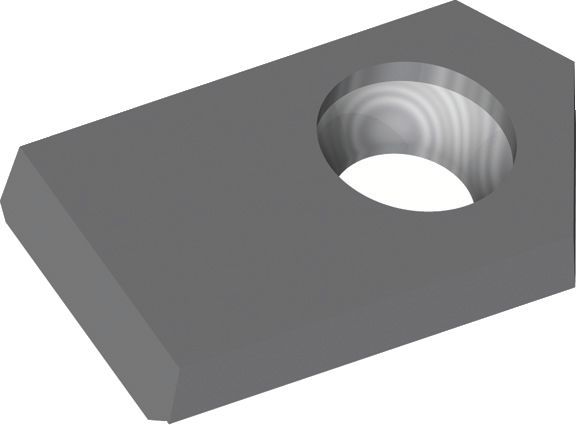

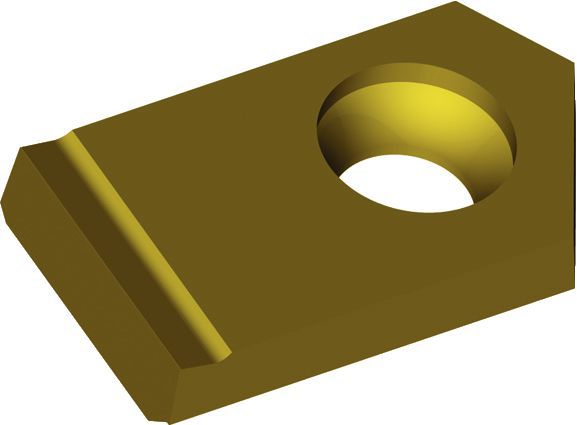

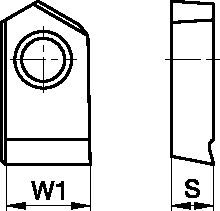

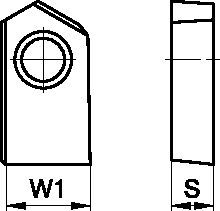

Insertos do chanfro BF • R900 S(T)F • Semiacabamento • CS5/KMF

Insertos BF

Características e benefícios

- Os corpos da broca padrão de aço foram projetados para insertos com chanfros de 41° e 45°.