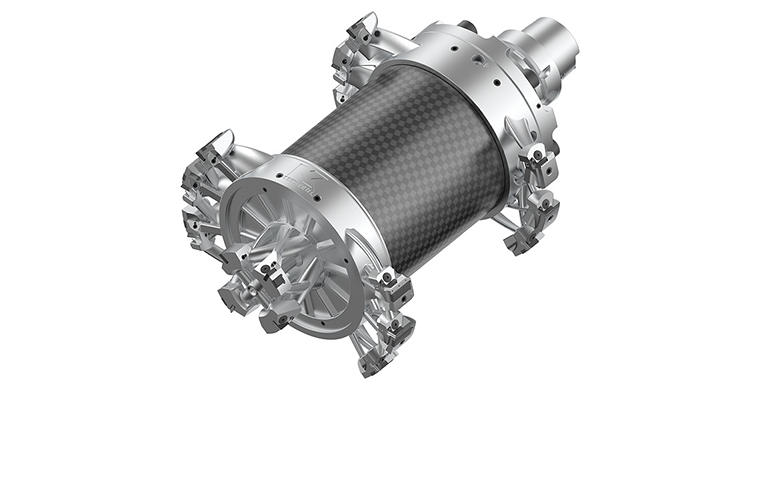

Ferramenta para furo do estator impressa em 3D para a usinagem de carcaças de motores eletrônicos de alumínio

Esta versão da ferramenta apresenta um novo projeto de estrutura de braço, um tubo central maior fabricado com fibra de carbono e com peso total de 7,3 kg.

A ferramenta complexa é capaz de usinar três diâmetros grandes em apenas uma operação, economizando tempo de configuração e tempo de usinagem para fabricantes de componentes automotivos e fornecendo a mais alta precisão e qualidade de superfície.

Usinando três diâmetros em uma operação, a ferramenta para furo do estator garante o alinhamento e a concentricidade das superfícies usinadas, reduzindo significativamente o tempo de ciclo.

A ferramenta de combinação leve e impressa em 3D permite uma troca de ferramenta e giro mais rápidos, mesmo em máquinas menos potentes.